Printing master batch of artificial synthetic fiber fabric applicable to printing forming technology

A synthetic fiber, artificial technology, applied in the direction of conjugated synthetic polymer rayon, fiber chemical characteristics, additive processing, etc., can solve the problems of unsuitability for popularization, environmental pollution damage, high cost, and achieve low cost and high price. Low, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

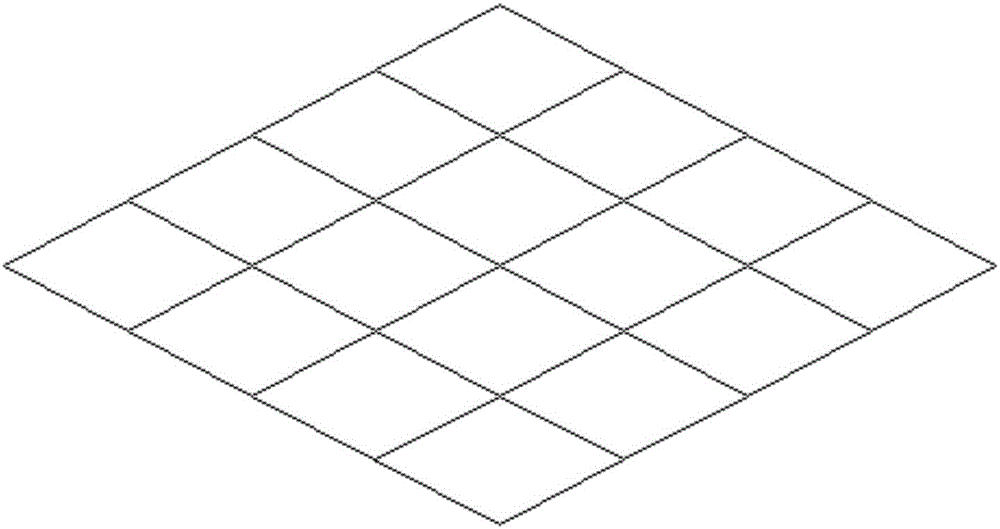

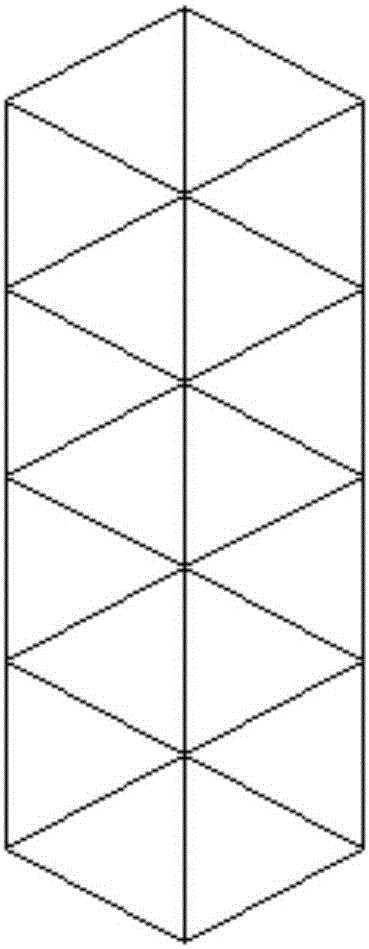

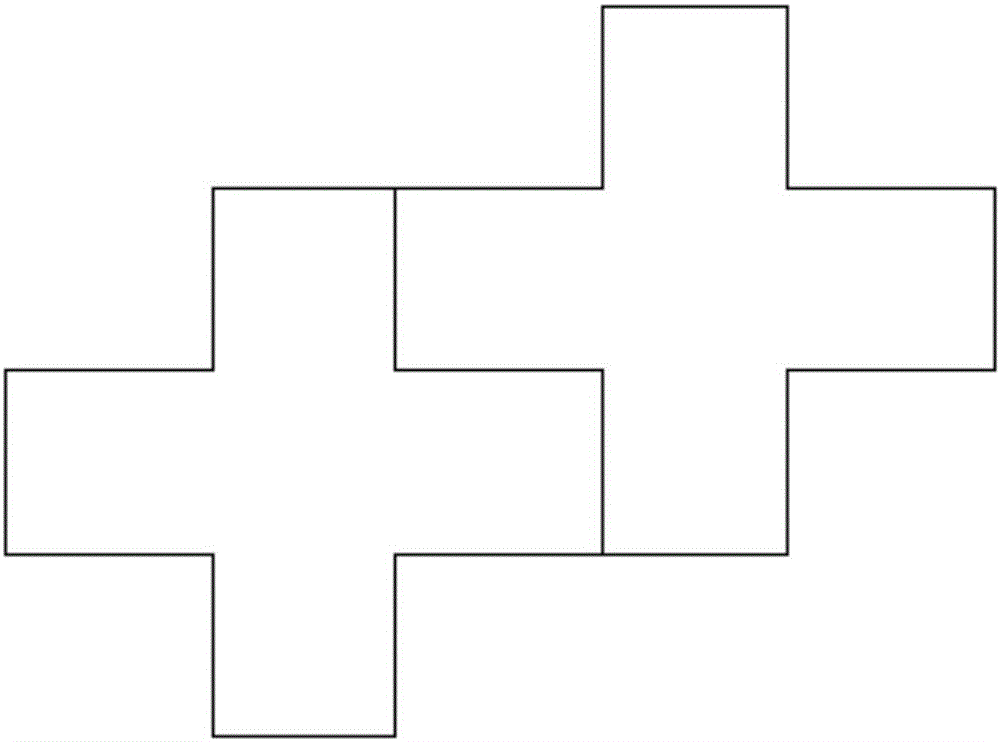

Image

Examples

Embodiment 1

[0035] The invention discloses a printing masterbatch for imitating artificial synthetic fiber fabric suitable for printing and forming technology, which is prepared from the following components according to mass percentage: polytetrafluoroethylene 25%, polyethylene terephthalate 15% %, polyimide fiber 23%, polyvinylidene chloride 7%, triphenyl phosphite 20%, polyvinyl chloride fiber 6%, basalt fiber 4%.

[0036] The present invention also provides a method for printing artificial synthetic fiber fabrics by using the above-mentioned printing masterbatch for imitating artificial synthetic fiber fabrics suitable for printing and forming technology, and the specific steps are as follows:

[0037] (1), according to above-mentioned mass percentage, take by weighing polytetrafluoroethylene, polyethylene terephthalate, polyimide fiber, polyvinylidene chloride, triphenyl phosphite, polyvinyl chloride fiber, basalt fiber and add into the mixer for mixing;

[0038] (2), add the mixed ...

Embodiment 2

[0044] The invention discloses a printing masterbatch for imitating artificial synthetic fiber fabric suitable for printing and forming technology, which is prepared from the following components according to mass percentage: polytetrafluoroethylene 20%, polyethylene terephthalate 15% %, polyimide fiber 25%, polyvinylidene chloride 10%, triphenyl phosphite 15%, polyvinyl chloride fiber 10%, basalt fiber 5%.

[0045] The present invention also provides a method for printing the artificial synthetic fiber fabric by using the above-mentioned printing masterbatch suitable for the printing and forming technology to imitate the artificial synthetic fiber fabric, and the specific steps are as follows:

[0046] (1), according to above-mentioned mass percentage, take by weighing polytetrafluoroethylene, polyethylene terephthalate, polyimide fiber, polyvinylidene chloride, triphenyl phosphite, polyvinyl chloride fiber, basalt fiber and add into the mixer for mixing;

[0047] (2), addin...

Embodiment 3

[0053] The invention discloses a printing masterbatch for imitating artificial synthetic fiber fabric suitable for printing and forming technology, which is prepared from the following components according to mass percentage: polytetrafluoroethylene 15%, polyethylene terephthalate 15% %, polyimide fiber 30%, polyvinylidene chloride 15%, triphenyl phosphite 10%, polyvinyl chloride fiber 7%, basalt fiber 8%.

[0054] The present invention also provides a method for printing the artificial synthetic fiber fabric by using the above-mentioned printing masterbatch suitable for the printing and forming technology to imitate the artificial synthetic fiber fabric, and the specific steps are as follows:

[0055] (1), according to above-mentioned mass percentage, take by weighing polytetrafluoroethylene, polyethylene terephthalate, polyimide fiber, polyvinylidene chloride, triphenyl phosphite, polyvinyl chloride fiber, basalt fiber and add into the mixer for mixing;

[0056] (2), add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com