A high-temperature smoke cooler-air heater system suitable for scr denitrification system

A technology of SCR reactor and air heater, which is applied in indirect heat exchangers, chemical instruments and methods, separation methods, etc., can solve the problem of worsening the blockage of ammonium hydrogen sulfate at the cold end, reducing catalyst activity, and worsening the blockage of ammonium hydrogen sulfate, etc. problems, to achieve the effect of enhancing the resistance to ammonium hydrogen sulfate clogging, improving self-mixing uniformity, and improving comprehensive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

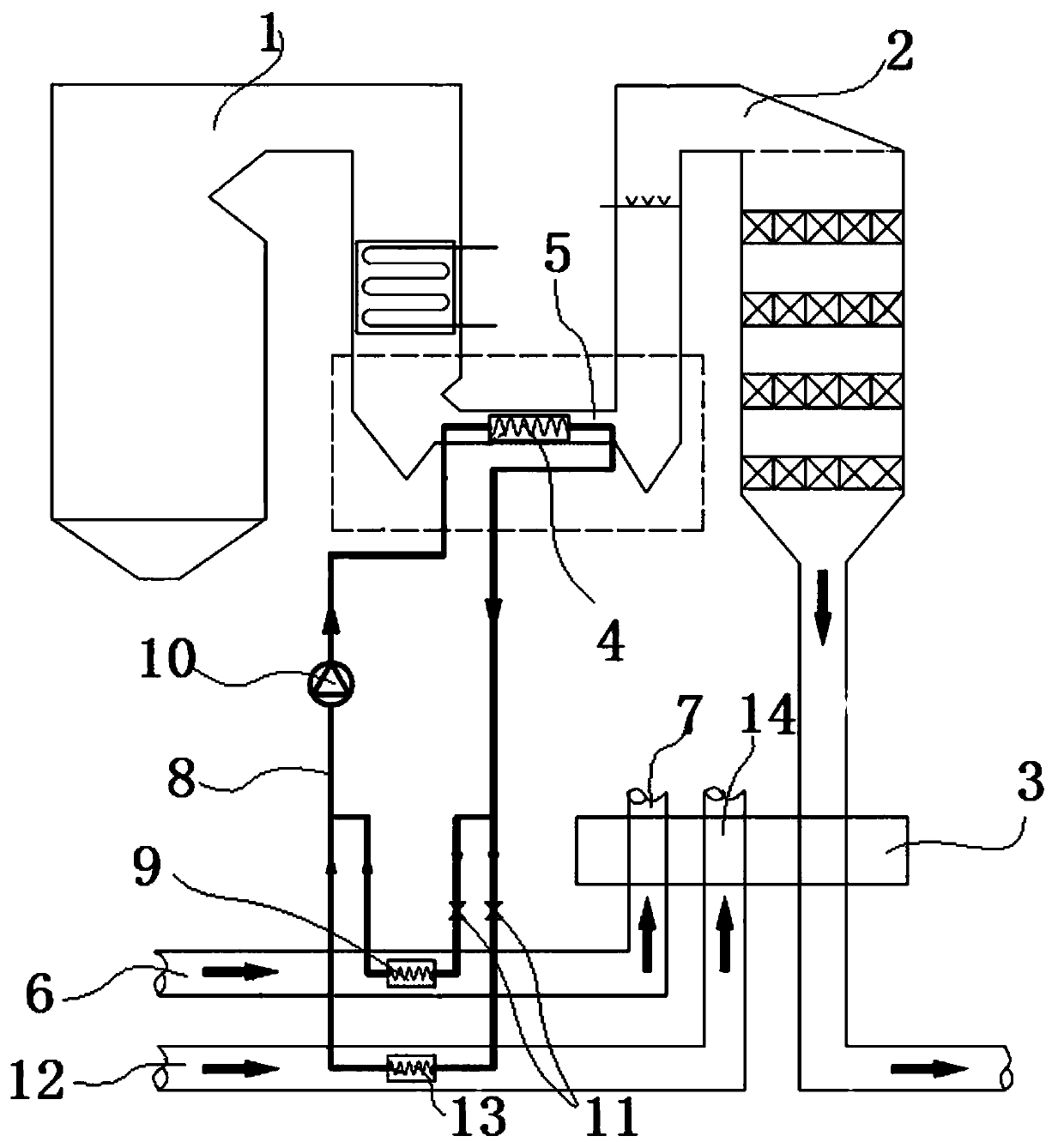

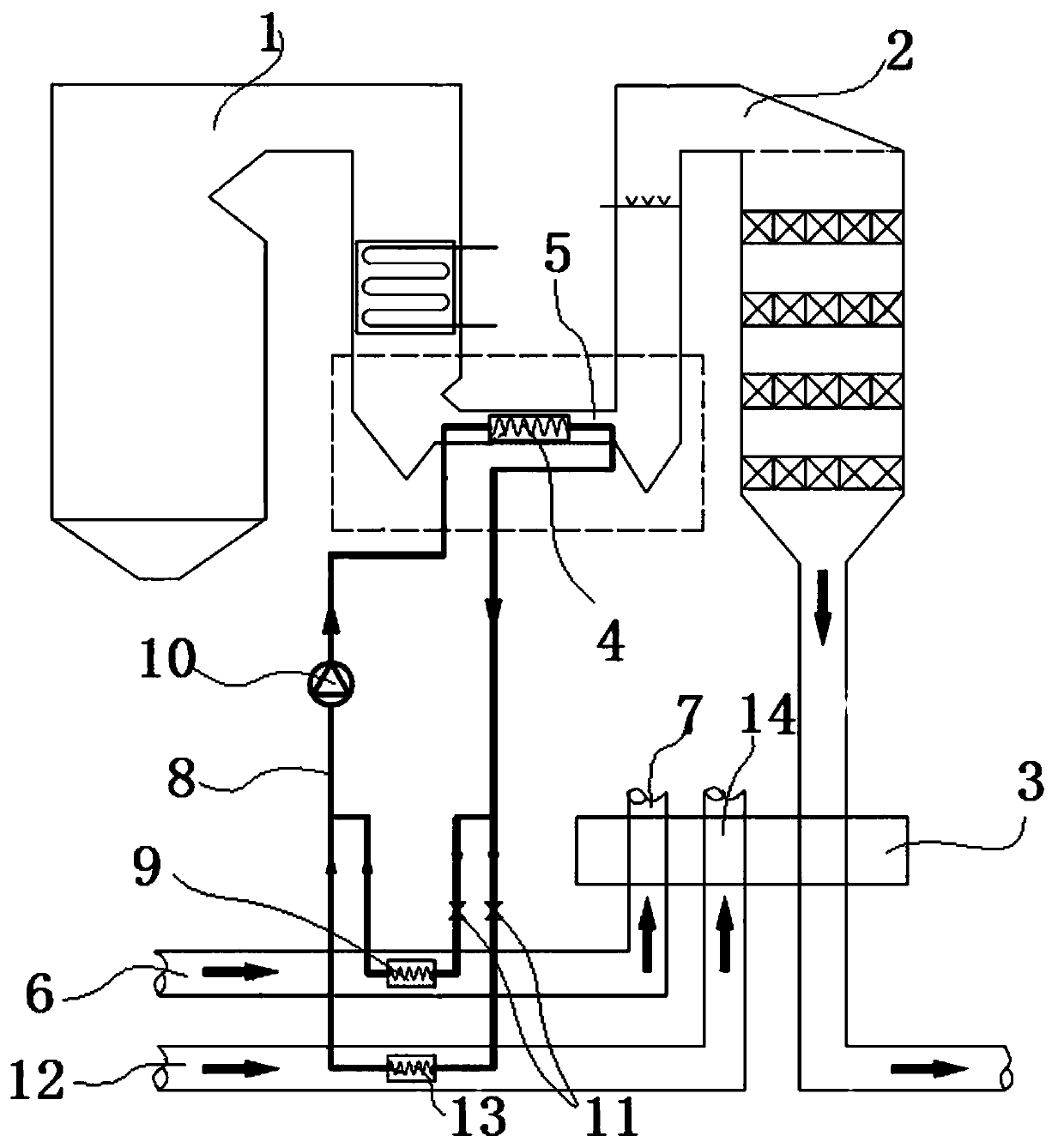

[0022] Such as figure 2 As shown, the flue 5 is used to connect the exhaust port of the boiler 1 with the flue gas inlet of the SCR reactor 2, specifically, the flue 5 is located between the economizer of the boiler 1 and the ammonia injection grid of the SCR reactor 2 Between, the flue gas inlet of the air preheater 3 communicates with the flue gas outlet of the SCR reactor 2 . The high-temperature smoke cooler-heater system suitable for SCR denitrification system includes flue gas condenser 4, primary fan, secondary fan, primary cold air channel 6, primary hot air channel 7, first air heater 9, secondary fan, Secondary cold air channel 12, secondary hot air channel 14, second heater 13, pipeline 8 and desalinated water.

[0023] The flue gas condenser 4 is arranged in the flue 5 . The primary cold air channel 6 is used to connect the outlet of the primary fan with the first air inlet of the air preheater 3, and the primary hot air channel 7 is used to connect the first ai...

Embodiment 2

[0030]Embodiment 2: The operation case of the high temperature smoke cooler-heater system suitable for SCR denitrification system using the above embodiment

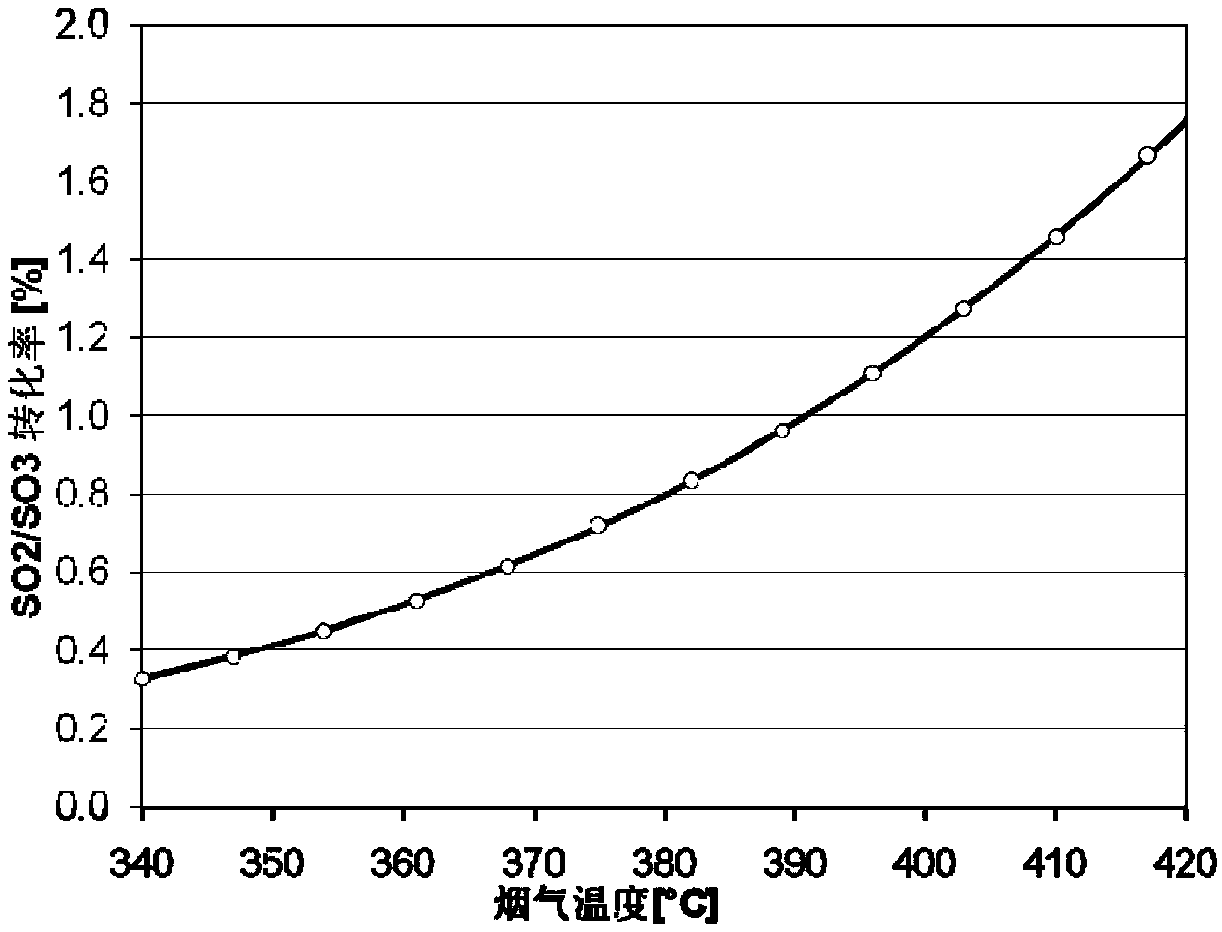

[0031] For a 600MW unit, the flue gas temperature at the SCR inlet under full load is about 410°C, the flue gas temperature under 350MW load is about 340°C, and the lowest continuous ammonia injection temperature is about 324.4°C. SO in SCR inlet flue gas 2 The concentration is about 2146μL / L, SO 3 The concentration is about 21.5μL / L. The designed SO of the SCR catalyst under full load 2 / SO 3 The conversion rate is 1.5%, SO in the flue gas at the inlet of air preheater 3 3 The concentration is about 56.2μL / L, and the blocking coefficient Nu of ammonium bisulfate ABS is 27061.

[0032] After the flue gas temperature is reduced from 410°C to 380°C through the flue gas condenser 4), the SO of the SCR catalyst 2 / SO 3 The conversion rate can be reduced from 1.5% to 0.8%, and the SO in the flue gas at the inlet of air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com