Two-dimensional tin selenide nanosheet-based surface enhanced Raman substrate and production method thereof

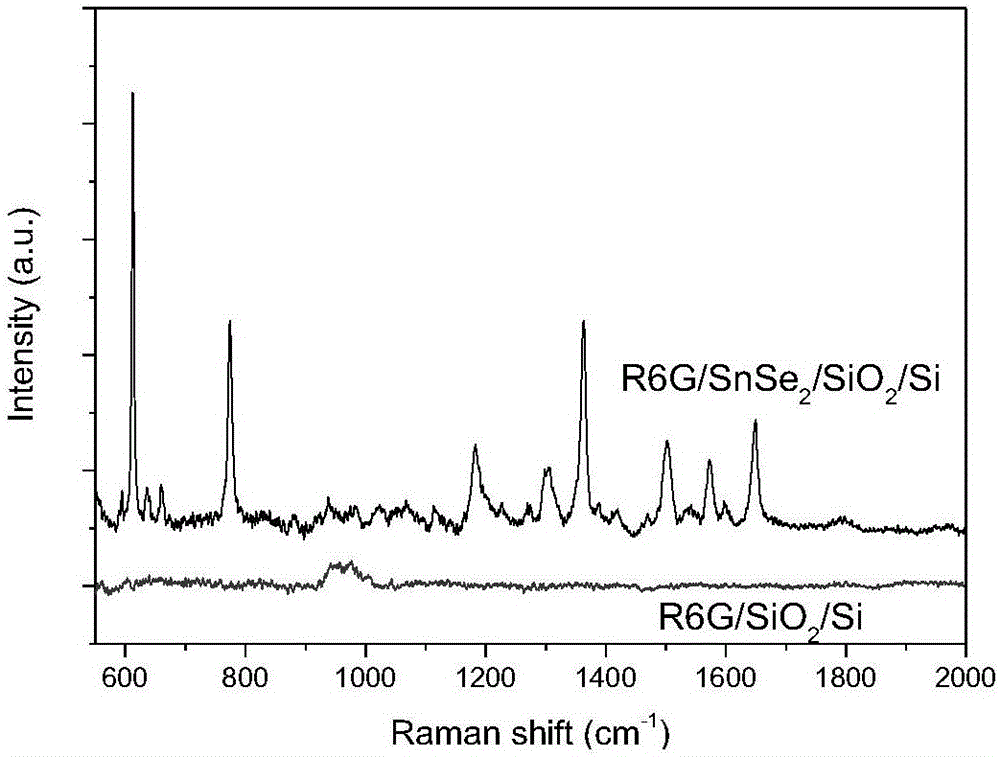

A technology of surface-enhanced Raman and tin selenide, applied in Raman scattering, measuring devices, instruments, etc., can solve the problems of weak Raman enhancement effect, and achieve cheap equipment, obvious Raman enhancement effect, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1, will be covered with 300nm SiO 2 The Si substrate of the oxide layer was cut into small square pieces of 1 cm×1 cm as the substrate.

[0046] Step 2, at room temperature, use an ultrasonic cleaning machine to clean the substrate in step 1, with an ultrasonic power of 180W and a frequency of 40kHz, and then use acetone, ethanol, and deionized water for ultrasonic cleaning in sequence, and the ultrasonic cleaning time is 20 minutes each time. Blow dry the surface of the substrate with nitrogen gas for use.

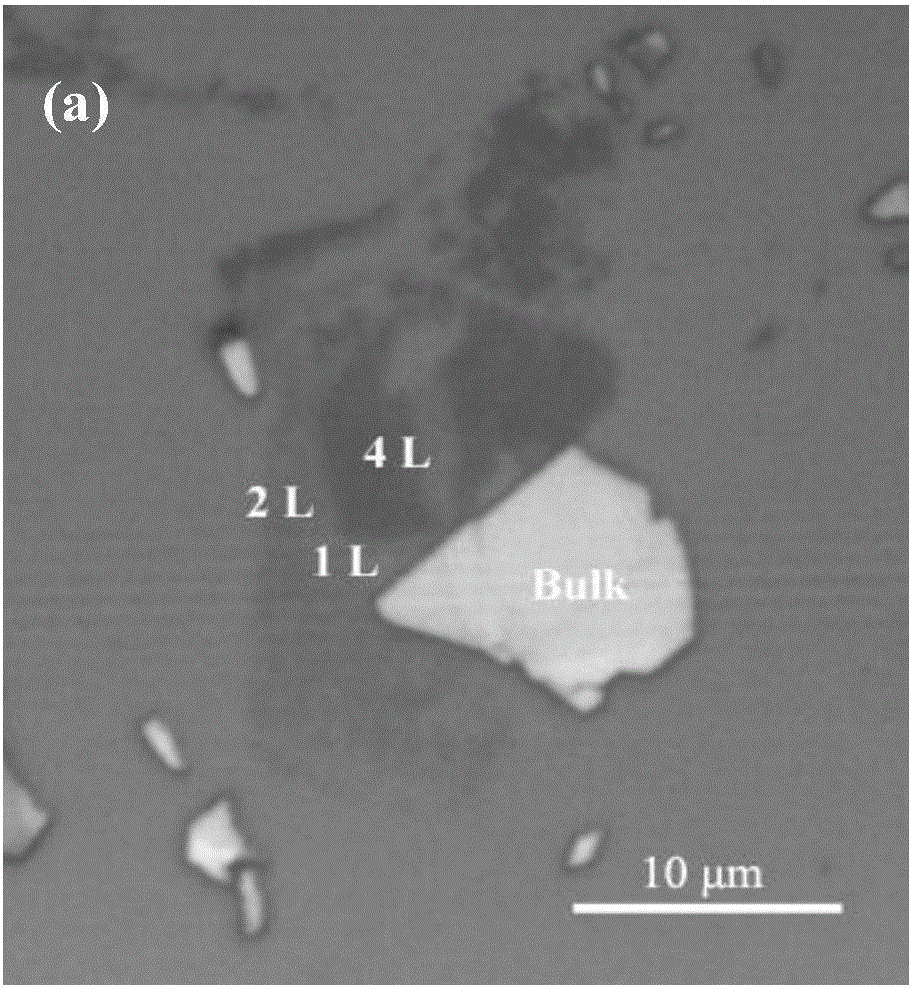

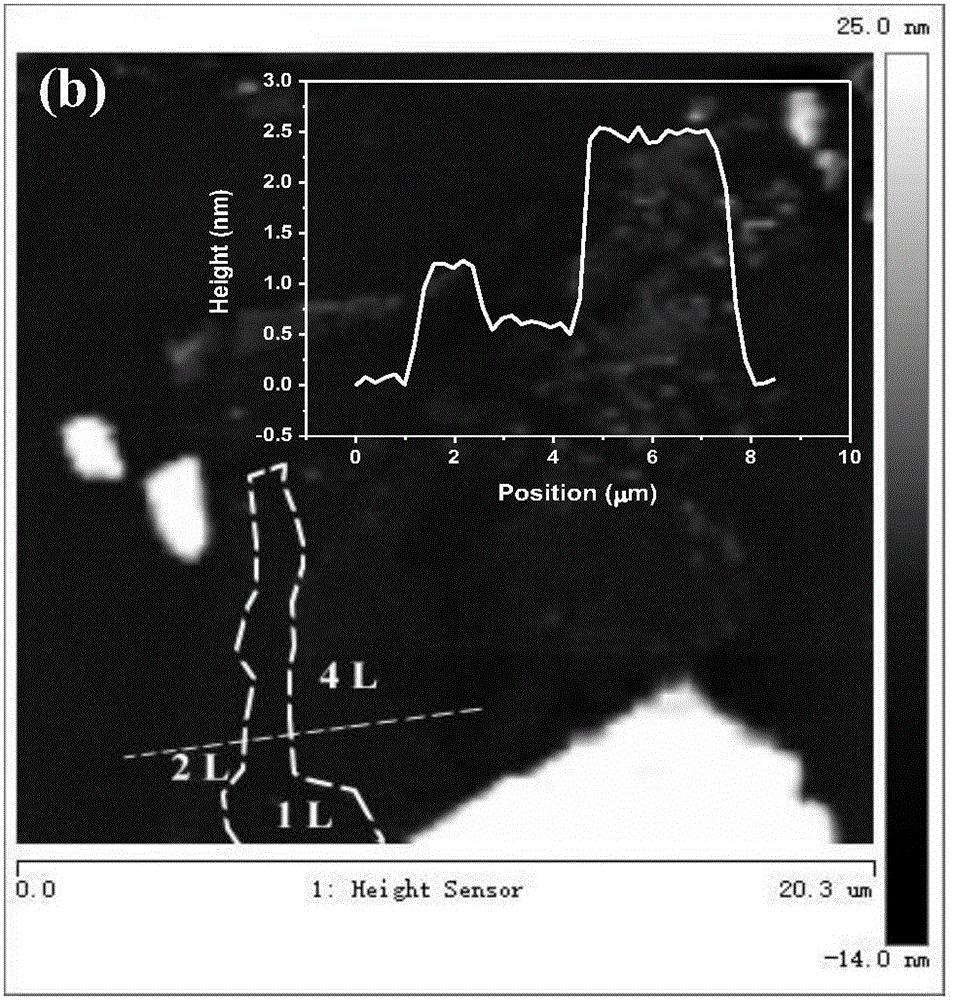

[0047] Step 3, cover the bulk SnSe with 5cm×2cm scotch tape 2 On the surface of the material, gently apply mechanical pressure, and then quickly tear it off, so that a layer of SnSe sticks on the surface of the tape 2 flakes, use another piece of tape of the same size, with SnSe 2 The position of the sheet tape is pasted, and quickly torn off after the pasting, and then the second piece of tape is repeatedly pasted, quickly torn off, and the above operation...

Embodiment 2

[0064] Step 1, will be covered with 300nm SiO 2 The Si substrate of the oxide layer was cut into small square pieces of 1 cm×1 cm as the substrate.

[0065] Step 2, at room temperature, use an ultrasonic cleaning machine to clean the substrate in step 1, with an ultrasonic power of 180W and a frequency of 40kHz, and then use acetone, ethanol, and deionized water for ultrasonic cleaning in sequence, and the ultrasonic cleaning time is 20 minutes each time. Blow dry the surface of the substrate with nitrogen gas for use.

[0066] Step 3, cover the bulk SnSe with 5cm×2cm scotch tape 2 On the surface of the material, gently apply mechanical pressure, and then quickly tear it off, so that a layer of SnSe sticks on the surface of the tape 2 flakes, use another piece of tape of the same size, with SnSe 2 The position of the sheet tape is pasted, and quickly torn off after the pasting, and then the second piece of tape is repeatedly pasted, quickly torn off, and the above operation...

Embodiment 3

[0074] Step 1, will be covered with 300nm SiO 2 The Si substrate of the oxide layer was cut into small square pieces of 1 cm×1 cm as the substrate.

[0075] Step 2, at room temperature, use an ultrasonic cleaning machine to clean the substrate in step 1, with an ultrasonic power of 180W and a frequency of 40kHz, and then use acetone, ethanol, and deionized water for ultrasonic cleaning in sequence, and the ultrasonic cleaning time is 20 minutes each time. Blow dry the surface of the substrate with nitrogen gas for use.

[0076] Step 3, cover the bulk SnSe with 5cm×2cm scotch tape 2On the surface of the material, gently apply mechanical pressure, and then quickly tear it off, so that a layer of SnSe sticks on the surface of the tape 2 flakes, use another piece of tape of the same size, with SnSe 2 The position of the sheet tape is pasted, and quickly torn off after the pasting, and then the second piece of tape is repeatedly pasted, quickly torn off, and the above operation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com