Hydrophilic and antibacterial dental implant system and manufacturing method thereof

An implant and hydrophilic technology, which is applied in the fields of dental implants, dentistry, and dental repairs, etc., to achieve the effect of improving surface hydrophilicity, facilitating adhesion and proliferation, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

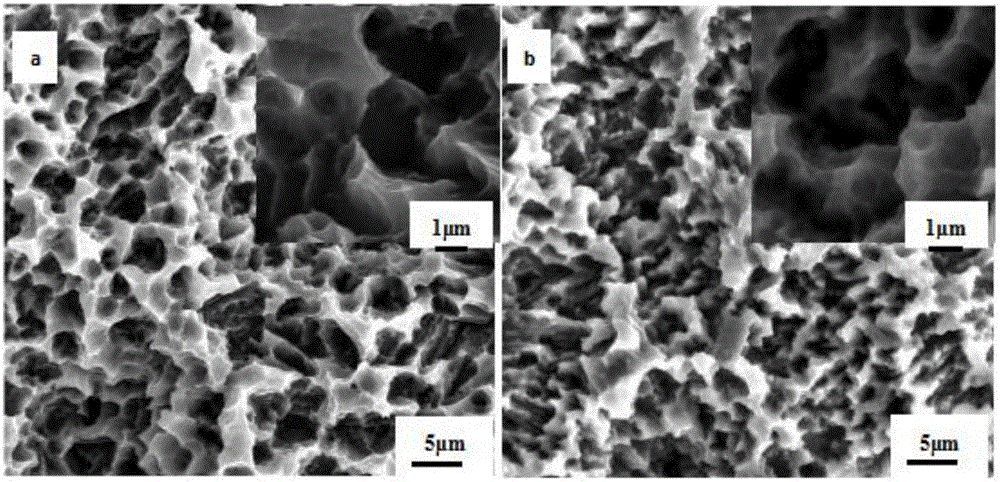

[0046] (1) Sample preparation: currently commercially used pure titanium dental implants (hereinafter referred to as SLA implants) treated by sandblasting and acid etching.

[0047] (2) Sample cleaning: Ultrasonic cleaning with deionized water for 5 minutes to wash off substrate surface attachments; then, ultrasonic cleaning with absolute ethanol for 5 minutes to deeply dissolve organic pollutants. After cleaning, dry it and put it in a vacuum chamber.

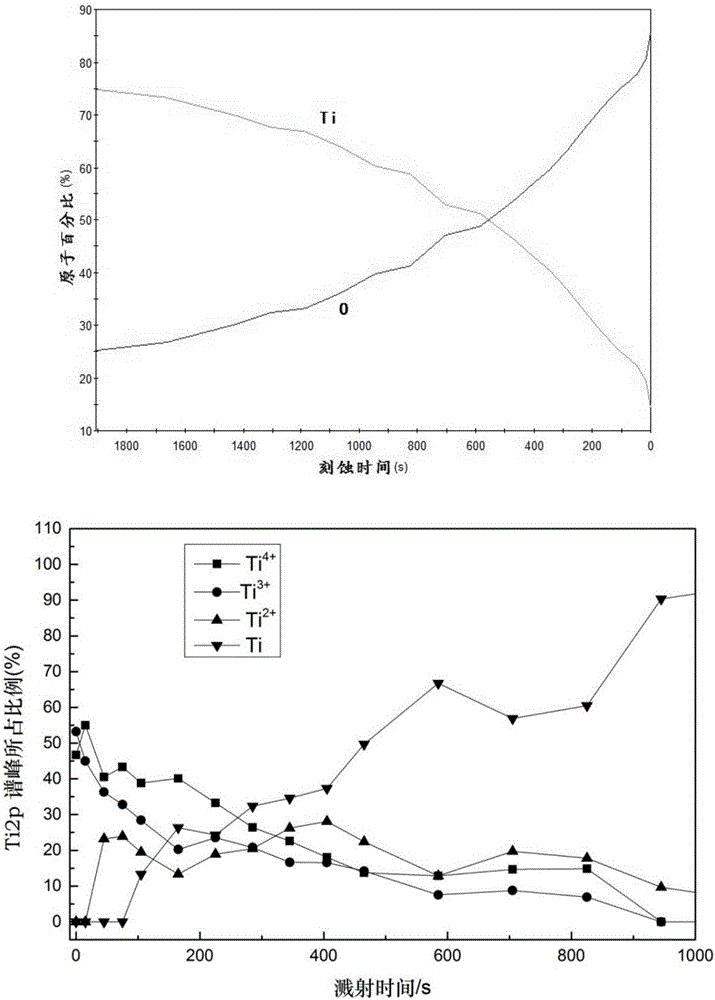

[0048] (3) Plasma cleaning: After evacuating to the background vacuum, inject 1-20 sccm of argon gas. After the pressure in the vacuum chamber is stable, turn on the RF power supply, adjust the RF power to 100W-400W, and adjust the reflected power to the lowest level as much as possible (should not More than 4% of the incident power), to generate glow discharge between the upper and lower electrode plates, adjust the angle valve to maintain the working pressure at 1-10Pa, use the argon plasma generated by glow discharge to bom...

Embodiment 2

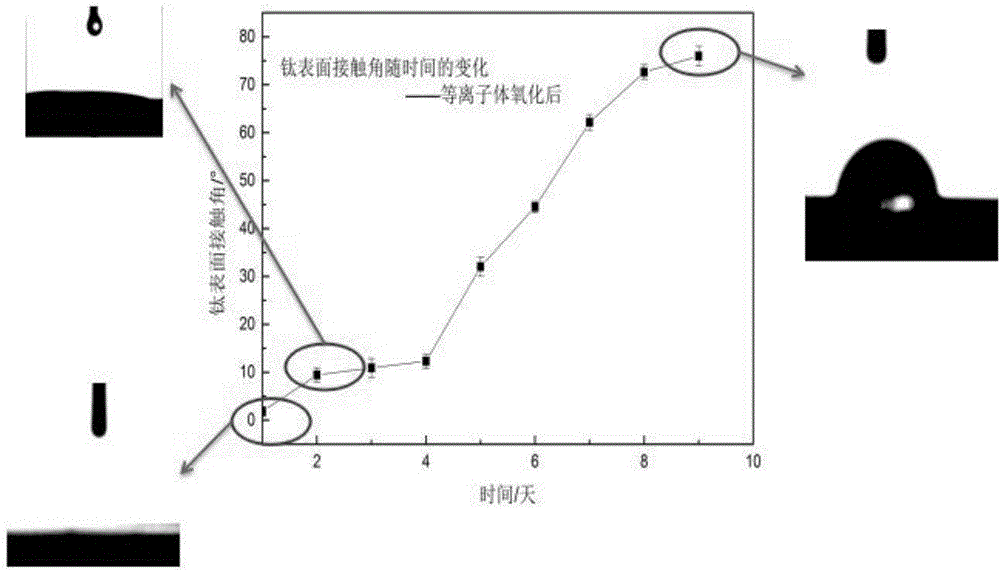

[0055] The sandblasted and acid-etched implants were subjected to plasma oxidation surface modification treatment, and then directly placed in the solution for storage. At different time periods, samples were taken out to test the contact angle. The results show that the hydrophilicity of the surface is well maintained, and the contact angles are all lower than 10°, maintaining the superhydrophilic characteristics. Available solutions include deionized water, alkaline solution or various salt solutions, etc. The solution storage method can isolate the direct contact between the implant and the air, avoid the contamination of the surface by the hydrocarbon groups in the air, thereby protecting the existence and content of the hydroxyl groups on the implant surface, and finally achieve the long-term stability of hydrophilicity .

[0056] The solution storage method is not only beneficial to maintain the hydrophilicity of the plasma oxidized implant, but also can grow nanostruct...

Embodiment 3

[0060] Protein adsorption experiments were carried out on the implants obtained through the above plasma oxidation and solution immersion storage treatments.

[0061] When implants osseointegrate, protein is first adsorbed on the surface of the material. Among them, the adsorption of serum albumin and fibronectin directly affects the behavior of osteoblasts in the later stage. The better the adsorption of these two proteins, the more favorable the biological behavior of osteoblasts.

[0062] The experimental process is as follows: place the sample titanium sheet in a 48-well plate, add 1ml of fibronectin (Fn) and bovine serum albumin (BSA) to the sample at 3 detection time points for each group, and add 1ml of fibronectin (Fn) and bovine serum albumin (BSA). Under certain conditions, after incubation for 3 h, 6 h, and 24 h, wash with PBS three times, then add 200 μL of sodium dodecyl sulfate (SDS, 1 wt%), shake in a shaker at room temperature for 1 hour, and then collect.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com