Ion exchange process for recovering tungsten from tungsten-containing diluted solution wastewater

An ion exchange and anion exchange column technology, applied in ion exchange water/sewage treatment, water pollutants, water/sewage treatment and other directions, can solve the problems of poor process index and use effect, shorten the time spent on desorption, The effect of increasing the exchange capacity and increasing the tungsten adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

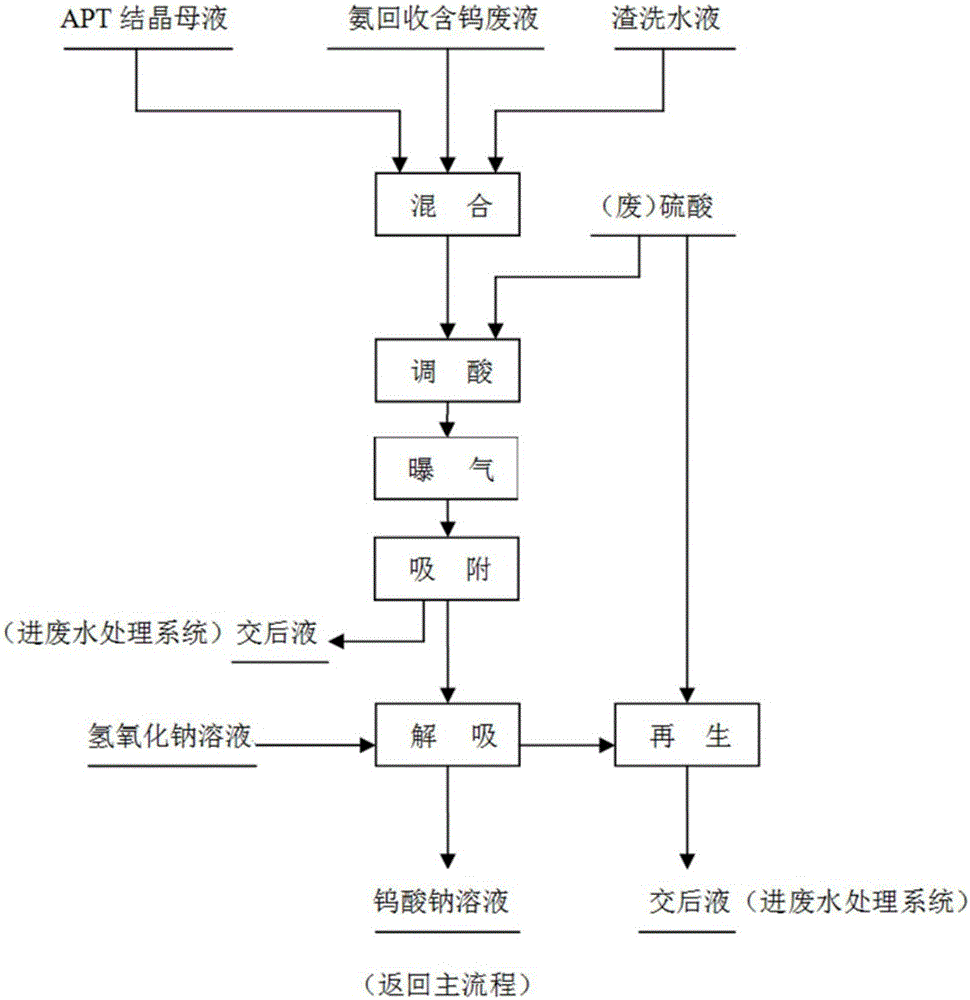

[0025] An ion exchange process for recovering tungsten from tungsten-containing dilute solution wastewater, such as figure 1 shown, including: the WO 3 Adjust the pH value of the tungsten-containing dilute solution wastewater with a concentration of 1g / L to 3.5, and then use compressed air to aerate for 30 minutes, every 200m 3 The wastewater containing dilute tungsten solution is aerated with a fan, and the air intake of each fan is 8m 3 / min, filter after the aeration is completed, and the obtained filtrate is the prepared liquid; the prepared liquid is pumped into the macroporous weak base anion exchange column D301 to adsorb tungsten, and the exchange flow rate is kept at 8m 3 / h, the NaOH solution of 80g / L is used to desorb the tungsten adsorbed by the ion exchange column after the adsorption is completed. After the desorption is completed, the resin in the exchange column is regenerated with sulfuric acid with a mass concentration of 130g / L (the recovery rate of tungste...

Embodiment 2

[0027] An ion exchange process for recovering tungsten from tungsten-containing dilute solution wastewater, such as figure 1 shown, including: the WO 3 Adjust the pH value of the tungsten-containing dilute solution wastewater with a concentration of 1g / L to 5, and then use compressed air to aerate for 60 minutes, every 200m 3 The wastewater containing dilute tungsten solution is aerated with a fan, and the air intake of each fan is 10m 3 / min, filter after the aeration is completed, and the obtained filtrate is the prepared liquid; the prepared liquid is pumped into the macroporous weak base anion exchange column D201 to adsorb tungsten, and the exchange flow rate is kept at 8m 3 / h, the NaOH solution of 80g / L is used to desorb the tungsten adsorbed by the ion exchange column after the adsorption is completed. After the desorption is completed, the resin in the exchange column is regenerated with sulfuric acid with a mass concentration of 130g / L (the recovery rate of tungsten...

Embodiment 3

[0029] An ion exchange process for recovering tungsten from tungsten-containing dilute solution wastewater, such as figure 1 shown, including: the WO 3The tungsten-containing dilute solution wastewater with a concentration of 1g / L is adjusted to pH 4.2 with concentrated sulfuric acid or waste acid solution, and then aerated with compressed air for 45 minutes, every 200m 3 The wastewater containing dilute tungsten solution is aerated with a fan, and the air intake of each fan is 9m 3 / min, filter after the aeration is completed, and the obtained filtrate is the prepared liquid; the prepared liquid is pumped into the macroporous weak base anion exchange column D314 to adsorb tungsten, and the exchange flow rate is kept at 8m 3 / h, the NaOH solution of 80g / L is used to desorb the tungsten adsorbed by the ion exchange column after the adsorption is completed. After the desorption is completed, the resin in the exchange column is regenerated with sulfuric acid with a mass concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com