A processing device and method for a flowback fracturing fluid

A technology of fracturing flowback fluid and treatment equipment, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., and can solve complex components, poor treatment effect, and large floor area and other problems, to achieve the effect of simple process flow, flexible and convenient use, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

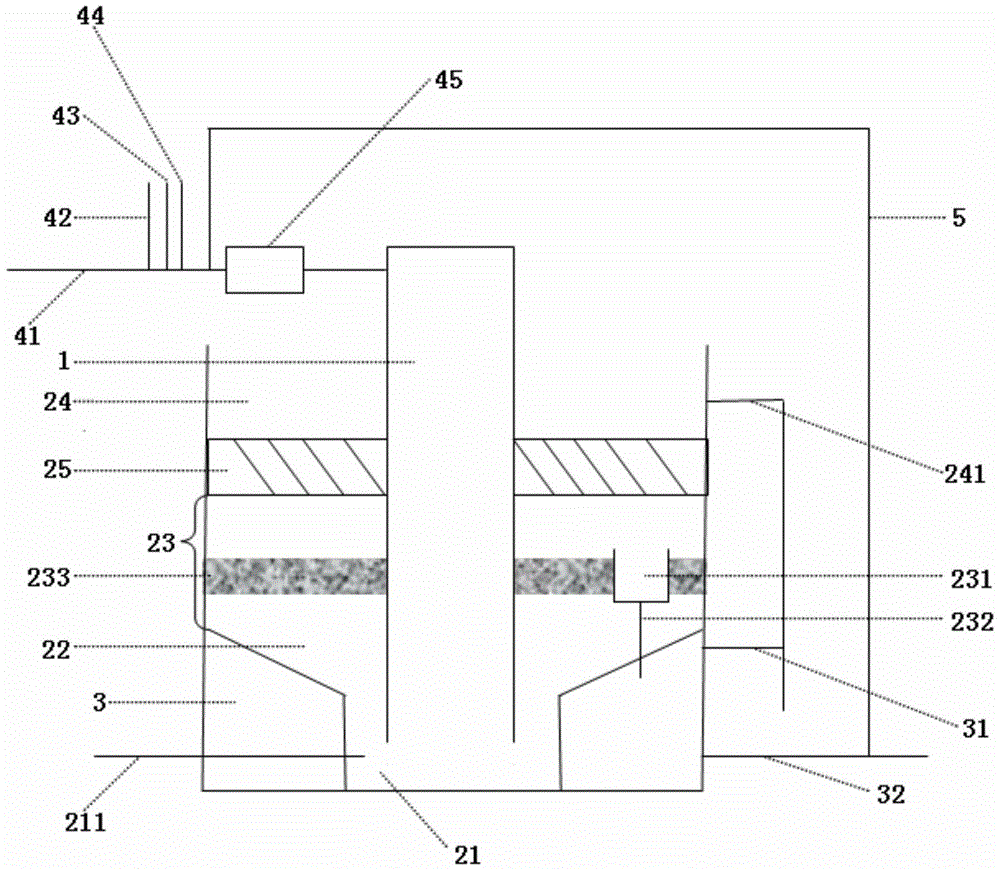

Image

Examples

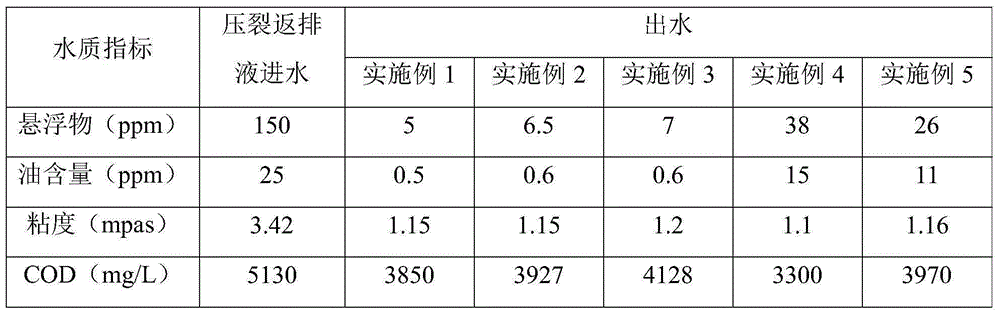

Embodiment 1

[0075] This embodiment is used to illustrate the method for treating fracturing flowback fluid using the device for treating fracturing flowback fluid of the present invention.

[0076] (1) Under the condition that the pH value of the fracturing flowback fluid is 3, the oxidation viscosity reduction reaction is carried out in the oxidation viscosity reduction reaction chamber 1 in the presence of an oxidizing agent and a catalyst. The oxidizing agent is 10% by weight of sodium persulfate solution, and the catalyst is It is a mixture of ferric chloride and calcium chloride, the weight ratio of ferric chloride and calcium chloride is 1:4, and the dosage of oxidant is 200ppm relative to the inflow of fracturing flowback fluid (based on the effective sodium persulfate concentration meter), the dosage of catalyst is 200ppm, and the hydraulic retention time in oxidation viscosity reduction reaction chamber 1 is 30min;

[0077] (2) The material after the step (1) reaction enters the ...

Embodiment 2

[0081] This embodiment is used to illustrate the method for treating fracturing flowback fluid using the device for treating fracturing flowback fluid of the present invention.

[0082] (1) Under the condition that the pH value of the fracturing flowback fluid is 4, the oxidation viscosity reduction reaction is carried out in the oxidation viscosity reduction reaction chamber 1 in the presence of an oxidizing agent and a catalyst. The oxidizing agent is 15% by weight of sodium persulfate solution, and the catalyst is It is a mixture of ferric chloride and calcium chloride, the weight ratio of ferric chloride and calcium chloride is 1:6, relative to the fracturing flowback fluid, the dosage of oxidant is 100ppm (based on the effective sodium persulfate concentration meter), the dosage of catalyst is 500ppm, and the hydraulic retention time in oxidation viscosity reduction reaction chamber 1 is 15min;

[0083] (2) The material after the step (1) reaction enters the mixing zone 2...

Embodiment 3

[0087] This embodiment is used to illustrate the method for treating fracturing flowback fluid using the device for treating fracturing flowback fluid of the present invention.

[0088] (1) Under the condition that the pH value of the fracturing flowback fluid is 5, the oxidation viscosity reduction reaction is carried out in the oxidation viscosity reduction reaction chamber 1 in the presence of an oxidizing agent and a catalyst. The oxidizing agent is 20% by weight of sodium persulfate solution, and the catalyst is It is a mixture of ferric chloride and calcium chloride, the weight ratio of ferric chloride and calcium chloride is 1:8, and the dosage of oxidant is 300ppm relative to the inflow of fracturing flowback fluid (based on the effective rate of sodium persulfate concentration meter), the dosage of catalyst is 350ppm, and the hydraulic retention time in oxidation viscosity reduction reaction chamber 1 is 45min;

[0089] (2) The material after the step (1) reaction ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com