Cu-BTC/polypyrrole nanowire/graphene nano composited material-based ammonia gas sensor, and preparation method thereof

A technology of nanocomposite materials and polypyrrole nanowires, which is applied in the field of ammonia sensors, can solve the problems of non-quantitative and other problems, achieve stable product performance, improve sensitivity and selectivity, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

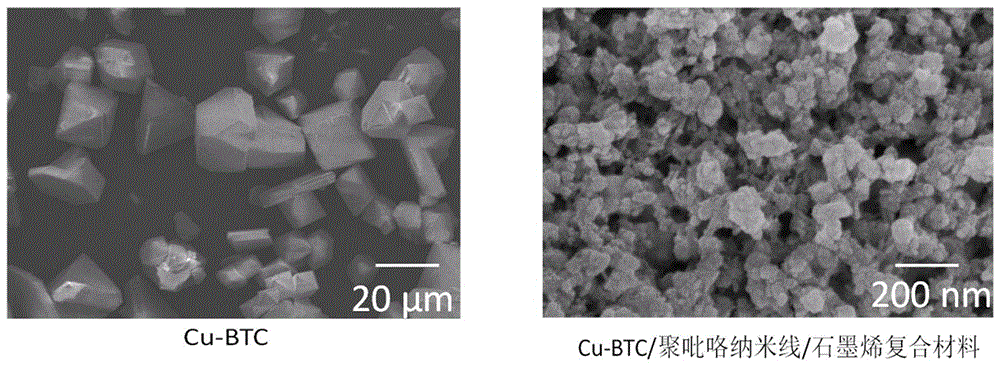

[0029] Preparation of ammonia gas sensor based on Cu-BTC / polypyrrole nanowire / graphene nanocomposite:

[0030] (1) Add 0.1 mol / L pyrrole, 0.1 mol / L cetyltrimethylammonium bromide, 0.1 mol / L citric acid and excess deionized water to the flask, and stir on a magnetic stirrer 3 hours;

[0031] (2) Step (1) Slowly add 20 mL of 0.5 mol / L ammonium persulfate solution into the mixture with a burette, continue stirring for 4 hours, filter, wash, and dry at 60°C;

[0032] (3) Add 0.5 g of the prepared polypyrrole nanowire / graphene composite into a solution containing 0.1 mol / L trimesic acid, 0.1 mol / L copper nitrate, 20 mL DMF, 12 mL ethanol and 8 mL water for ultrasonic dispersion 1h;

[0033] (4) Transfer the solution in step (3) to the reaction kettle, cover it, and place it in an oven at 80°C for 24 hours, filter, wash, and dry to obtain Cu-BTC / polypyrrole nanowires / graphene nanocomposites , and then load it on the ITO conductive glass;

[0034] (5) Paste two conductive copper ...

Embodiment 2

[0040] Preparation of ammonia gas sensor based on Cu-BTC / polypyrrole nanowire / graphene nanocomposite:

[0041] (1) Add 0.2 mol / L of pyrrole, 0.15 mol / L of cetyltrimethylammonium bromide, 0.2 mol / L of citric acid and excess deionized water into the flask, and stir on a magnetic stirrer 3 hours;

[0042] (2) Step (1) Slowly add 30 mL of 0.5 mol / L ammonium persulfate solution to the mixture with a burette, continue stirring for 4 hours, filter, wash, and dry at 60°C;

[0043](3) Add 0.5 g of the prepared polypyrrole nanowire / graphene composite into a solution containing 0.1 mol / L trimesic acid, 0.2 mol / L copper nitrate, 12 mL DMF, 15 mL ethanol and 8 mL water for ultrasonication Disperse for 1h;

[0044] (4) Transfer the solution in step (3) to the reaction kettle, cover it, place it in an oven at 85°C for 24 h, filter, wash, and dry to obtain Cu-BTC / polypyrrole nanowire / graphene nanocomposite Material;

[0045] (5) Paste two conductive copper foils on the ITO conductive glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com