Plant acne-removing compound as well as preparation method and applications thereof

A compound, acne-removing technology, applied in the directions of drug combinations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of large side effects of sulfur and benzoyl peroxide, drug resistance and allergy, etc., and achieve the inhibition of acne propionic acid. Bacillus, low irritant, accelerates shedding of epidermal keratinocytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

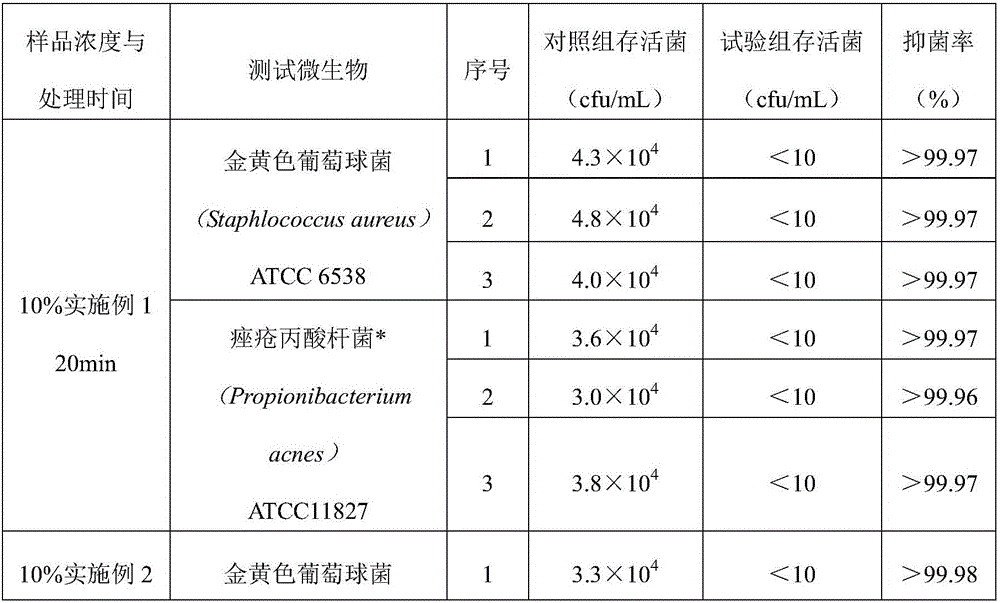

Embodiment 1

[0039] Embodiment 1: the preparation of plant anti-acne compound

[0040] (1) Preparation of shallot extract: take 1 mass part of shallot, add 10 mass parts of 95% (w / w) ethanol to soak for 3 hours, then heat to 50°C for 3 hours, filter and recover the extract with 200-mesh filter cloth , ethanol is recovered by distillation under reduced pressure to obtain a thick paste containing the shallot extract, adding 1 mass part of glycerin to disperse the thick paste, adding 3 mass parts of propylene glycol to dissolve, passing through 200 mesh gauze to obtain the shallot extract.

[0041] (2) Preparation of wild chrysanthemum extract: Take 1 part by mass of wild chrysanthemum, add 10 parts by mass of 20% (w / w) propylene glycol aqueous solution, heat in a water bath at 80° C. for 3 hours, and filter through a 200-mesh filter cloth to obtain wild chrysanthemum extract.

[0042] (3) Preparation of lotus leaf extract: Take 1 part by mass of lotus leaf, add 30 parts by mass of 20% (w / w) ...

Embodiment 2

[0044] Embodiment 2: the preparation of plant anti-acne compound

[0045] (1) Preparation of shallot extract: take 3 parts by mass of shallot, add 15 parts by mass of 95% (w / w) ethanol, soak for 5 hours, then heat to 60°C and soak for 4 hours, filter and extract with 200-mesh filter cloth liquid, and the ethanol was recovered by distillation under reduced pressure to obtain a thick paste containing the shallot extract, adding 3 parts by mass of glycerin to disperse the thick paste, adding 10 parts by mass of propylene glycol to dissolve, and passing through 200 mesh gauze to obtain the shallot extract.

[0046] (2) Preparation of wild chrysanthemum extract: take 1 mass part of wild chrysanthemum, add 30 mass parts of 20% (w / w) propylene glycol aqueous solution, heat in a water bath at 80° C. for 4 hours, and filter through a 200-mesh filter cloth to obtain wild chrysanthemum extract.

[0047] (3) Preparation of lotus leaf extract: take 1 part by mass of lotus leaf, add 10 part...

Embodiment 3

[0049] Embodiment 3: the preparation of plant anti-acne compound

[0050] (1) Preparation of shallot extract: Take 5 parts by mass of shallot, add 20 parts by mass of 95% (w / w) ethanol, soak for 6 hours, then heat to 70°C and soak for 5 hours, filter and extract with 200-mesh filter cloth Liquid, the ethanol is recovered by distillation under reduced pressure to obtain a thick paste containing the shallot extract, add 3 parts by mass of glycerin to disperse the thick paste, add 15 parts by mass of propylene glycol to dissolve, pass through 200 mesh gauze, and obtain the shallot extract.

[0051] (2) Preparation of wild chrysanthemum extract: take 1 mass part of wild chrysanthemum, add 20 mass parts of 20% (w / w) propylene glycol aqueous solution, heat in a water bath at 80° C. for 5 hours, and filter through a 200-mesh filter cloth to obtain wild chrysanthemum extract.

[0052] (3) Preparation of lotus leaf extract: take 1 part by mass of lotus leaf, add 30 parts by mass of 20%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com