Efficient synthetic method for series of spinel nanostructured materials

A technology of nanostructures and synthesis methods, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve complex steps, high cost, unsuitable for mass production and other problems, to achieve the effect of simple reaction device, realization of industrial scale production, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

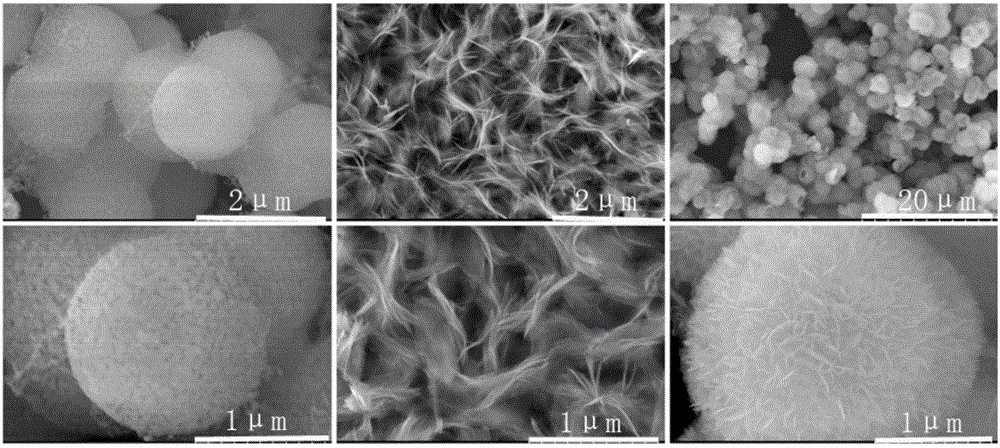

[0020] Embodiments of the present invention include the following steps:

[0021] 1) Dissolving the soluble salt of A and the soluble salt of B in an alcoholic solvent and stirring to obtain a mixed solution; the A is selected from one of Mg, Zn, Ni, Co, Ca, Cu, rare earth element Ln, etc. ; The B is selected from one of Al, Si, Cr, Bi, Fe, Ga, etc.; the soluble salt adopts nitrate or chloride etc.; the mol ratio of the soluble salt of A and the soluble salt of B can be The ratio is 1:2; the alcohol solvent can be selected from at least one of ethanol, propanol, butanol, hexanol, etc.; the stirring time can be 1 h.

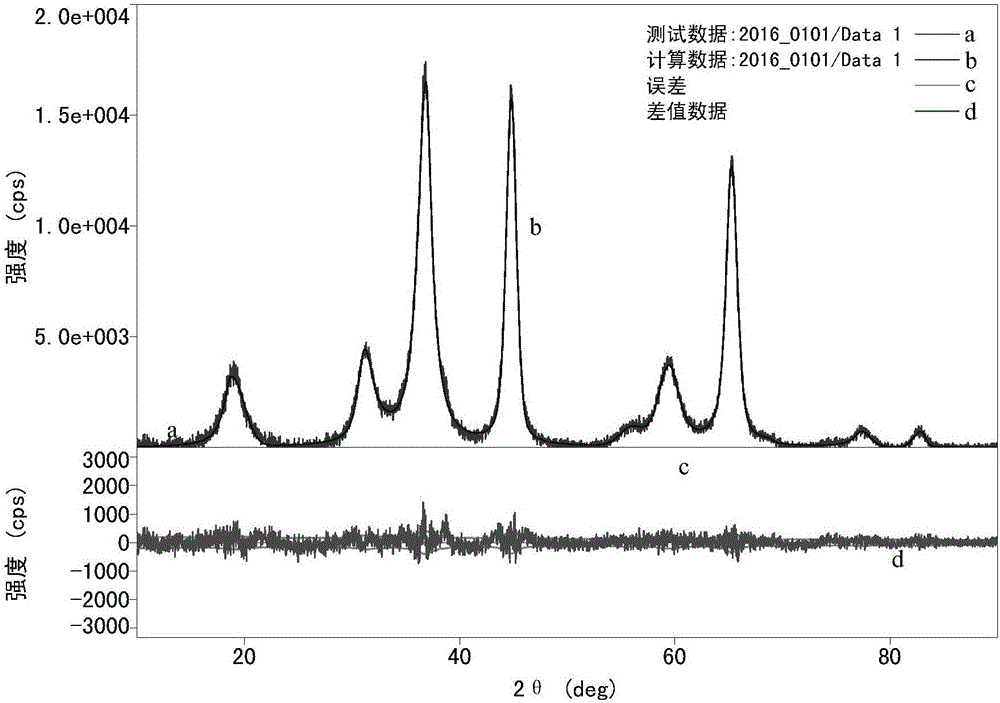

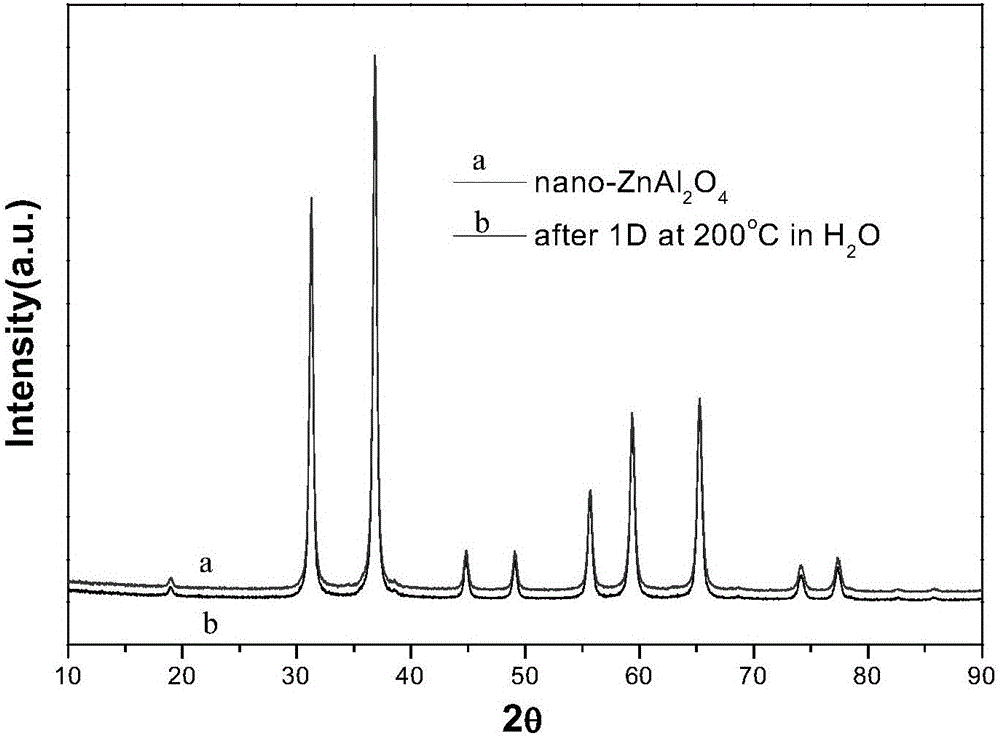

[0022] 2) Transfer the mixed solution obtained in step 1) to an autoclave for reaction, and centrifuge to obtain a precursor product; the autoclave can be an autoclave lined with polytetrafluoroethylene; the temperature of the reaction can be 200 °C, the reaction time can be 24h.

[0023] 3) Calcining the precursor product obtained in step 2) to obtain a series ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com