Alloy-supported aromatic hydrocarbon saturation catalyst and preparation method thereof

A catalyst and alloy-type technology, applied in the field of supported alloy-type aromatic hydrocarbon saturation catalyst and its preparation, can solve the problems of low saturation and uncontrollable degree of hydrogenation of polycyclic aromatic hydrocarbons, etc., and achieve strong saturation ability, good stability and good stability. The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

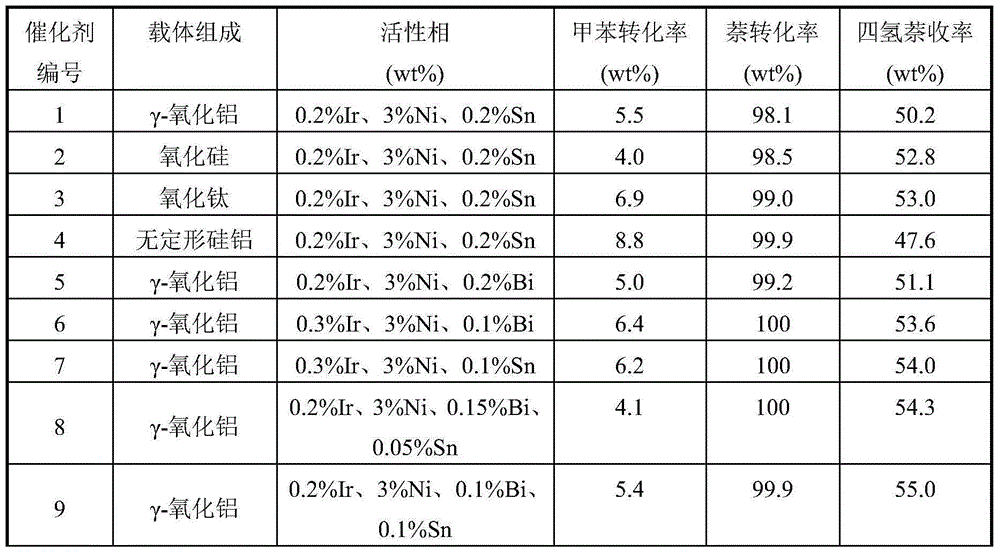

Embodiment 1

[0029] Add 2.4g of scallop powder to 80g of γ-alumina (commercially purchased) on a dry basis and mix well, then add 4g of HNO at a volume ratio of 1:1 3 aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0030] The mixed solution of chloroiridic acid, nickel nitrate, and tin chloride was impregnated to the carrier particles at 40°C, and the dry basis weight of the carrier contained in the impregnating solution was 0.2%Ir, 3%Ni and 0.2%Sn, aged for 8h and After drying, it was oxidized in air at 1000°C for 4 hours, and then reduced in hydrogen at 700°C for 4 hours (this step can be completed in a reactor) to obtain the finished catalyst 1.

[0031] Catalyst 1 was used to evaluate the hydroge...

Embodiment 2

[0033] Add 2.4g of kale powder to 80g of silica (commercially purchased) on a dry basis and mix well, then add 4g of HNO with a volume ratio of 1:1 3 aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0034] The mixed solution of chloroiridic acid, nickel nitrate, and tin chloride was impregnated to the carrier particles at 40°C, and the dry basis weight of the carrier contained in the impregnating solution was 0.2% Ir, 3% Ni and 0.2% Sn, aged for 8h and After drying, it was oxidized in air at 1000°C for 4 hours, and then reduced in hydrogen at 700°C for 4 hours (this step can be completed in a reactor) to obtain the finished catalyst 2.

[0035] Catalyst 2 was used to evaluate the hydrogenation ...

Embodiment 3

[0037] Add 2.4g of scallop powder to 80g of titanium oxide (commercially purchased) on a dry basis and mix well, then add 4g of HNO at a volume ratio of 1:1 3 aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0038] The mixed solution of chloroiridic acid, nickel nitrate, and tin chloride was impregnated to the carrier particles at 40°C, and the dry basis weight of the carrier contained in the impregnating solution was 0.2%Ir, 3%Ni and 0.2%Sn, aged for 8h and After drying, it was oxidized in air at 1000°C for 4 hours, and then reduced in hydrogen at 700°C for 4 hours (this step can be completed in a reactor) to obtain the finished catalyst 3.

[0039] Catalyst 3 was used to evaluate the hydrogenat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com