Carbonate type high-silicon bauxite beneficiation method

A technology of high-silicon bauxite and ore dressing method, which is applied in flotation, solid separation, etc., and can solve the problem of ineffective removal of carbonate impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the present embodiment takes high-grade Yunnan carbonate type high-silicon bauxite as the research object, and Al in the ore 2 o 3 The grade is 42.94%, SiO 2 The content is 17.30%, and the aluminum-silicon ratio is 2.48; the gangue minerals are mainly quartz, dolomite, kaolinite and calcite.

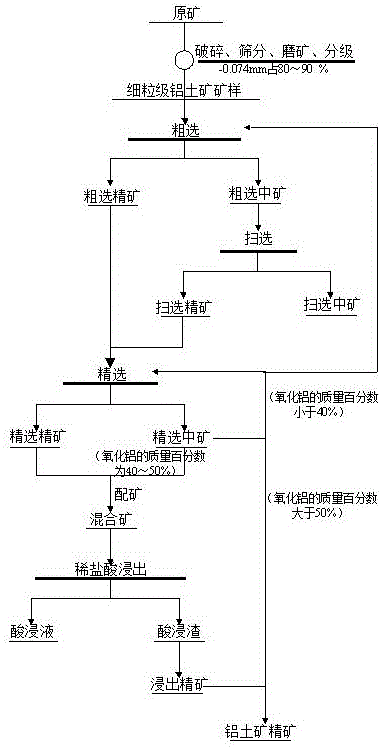

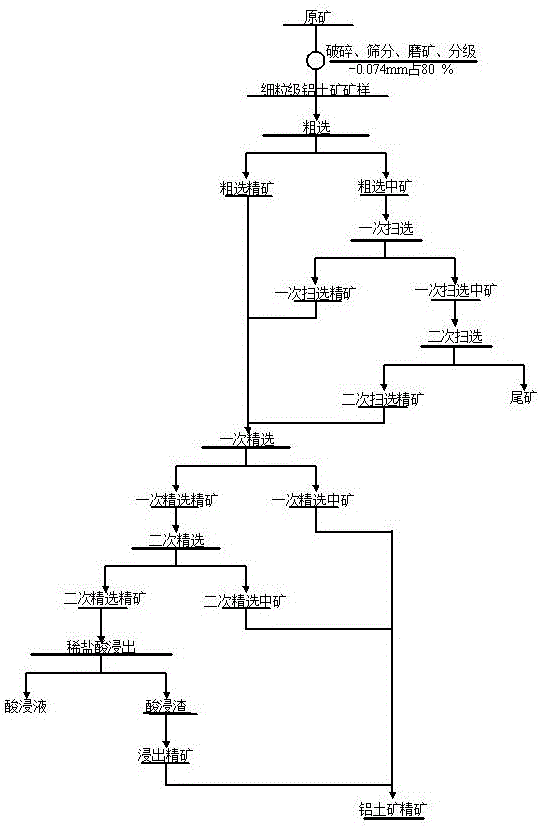

[0033] Such as figure 1 and 2 Shown, a kind of beneficiation method of carbonate type high-silicon bauxite, concrete steps are as follows:

[0034] (1) Crushing, screening, grinding, and grading the raw ore to -0.074 mm accounted for 80% to obtain fine-grained bauxite ore samples;

[0035] (2) Add 400g / t of sodium oleate, 1000g / t of water glass, and 100g / t of No. 2 oil to the fine-grained bauxite sample in step (1), and roughen for 4 minutes to obtain the roughened concentrate and rough beneficiation; wherein the mass percentage of alumina in the rough beneficiation concentrate is 46.42%, the mass percentage of silicon dioxide is 6.27%, and the mass ratio of alu...

Embodiment 2

[0055] Embodiment 2: the present embodiment takes the low-grade Yunnan carbonate type high-silicon bauxite as the research object, and Al in the ore 2 o 3 The grade is 18.73%, SiO 2 The content of CaO and MgO in the ore is 8.34%, and the ratio of aluminum to silicon is 2.24; the content of CaO in the ore is 7.63%, and the content of MgO is 8.42%. CaO and MgO mainly exist in the form of calcite and dolomite. Calcite etc.

[0056] Such as figure 1 and 4 Shown, a kind of beneficiation method of carbonate type high-silicon bauxite, concrete steps are as follows:

[0057] (1) Crushing, screening, grinding, and grading the raw ore to -0.074 mm accounted for 85% to obtain fine-grained bauxite ore samples;

[0058] (2) Add 200g / t of sodium oleate, 600g / t of water glass, and 60g / t of No. 2 oil to the fine-grained bauxite sample in step (1), and roughen for 4 minutes to obtain the roughened concentrate and Rough beneficiation; wherein the mass percentage of alumina in the rough be...

Embodiment 3

[0076] Embodiment 3: the present embodiment takes high-grade Guangxi carbonate type high-silicon bauxite as the research object, and Al in the ore 2 o 3 The grade is 27.64%, SiO 2 The content is 8.67%, and the aluminum-silicon ratio is 3.19; the gangue minerals are mainly quartz, dolomite, kaolinite and calcite.

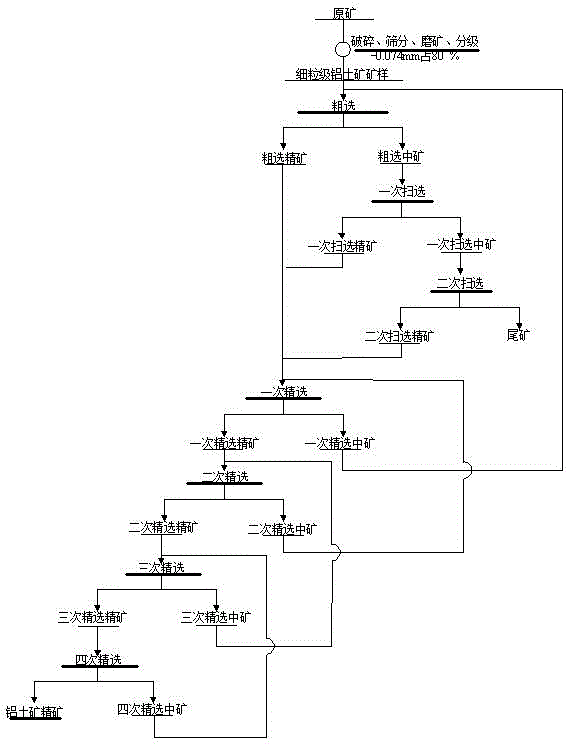

[0077] Such as figure 1 and 6 Shown, a kind of beneficiation method of carbonate type high-silicon bauxite, concrete steps are as follows:

[0078] (1) Crushing, screening, grinding, and grading the raw ore to -0.074 mm accounts for 90% to obtain fine-grained bauxite ore samples;

[0079] (2) Add sodium oleate 300g / t, water glass 800g / t, and No. 2 oil 80g / t to the fine-grained bauxite ore sample in step (1) in sequence, and roughen for 4 minutes to obtain the roughened concentrate and rough concentrate; wherein the mass percentage of alumina in the rough concentrate is 45.57%, the mass percentage of silica is 5.82%, and the mass ratio of alumina to silica is 7.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com