Weighing and transportation system for industrial starch after bagging

An industrial starch and transportation system technology, applied in transportation and packaging, packaging, conveyors, etc., can solve problems such as low efficiency, inability to balance precision and efficiency, and abandonment, and achieve compact production process, strong load-bearing capacity, and improved production volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

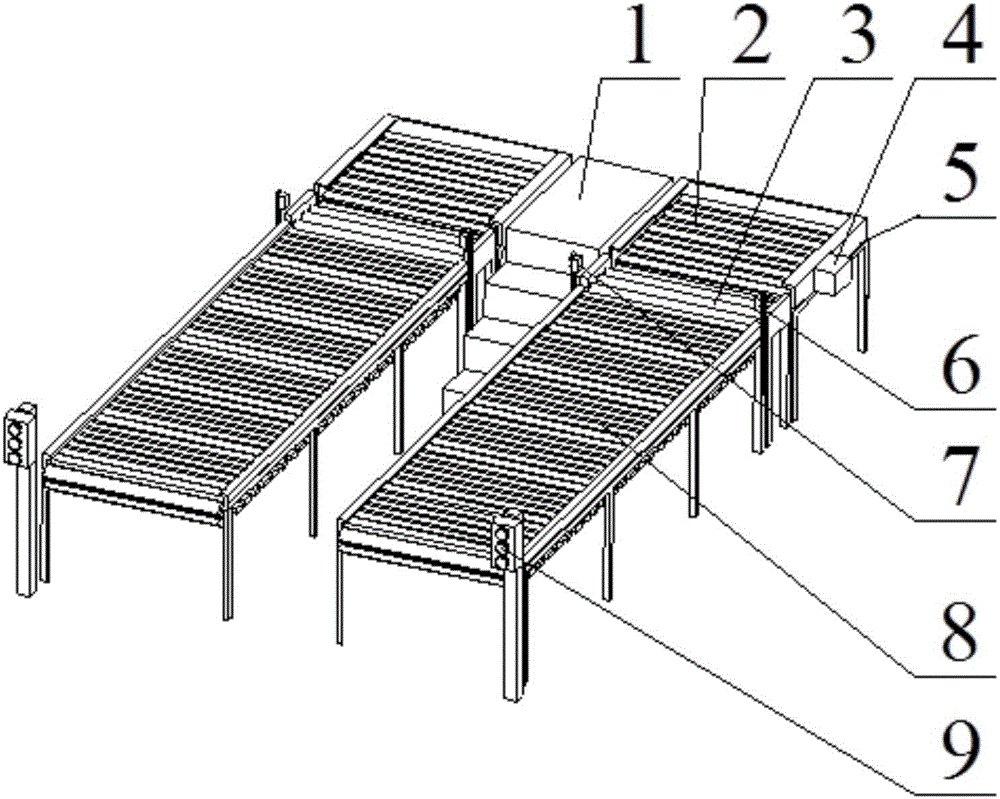

[0026] A weighing transportation system after industrial starch is bagged, such as figure 1 As shown, it is used to weigh and transport the bagged industrial starch, including a weighing platform 5 and a transport crawler 8, and the weighing platform 5 is used to place the bagged industrial starch and weigh the bagged industrial starch , the transport crawler 8 is docked with the weighing platform 5 for the transportation of industrial starch after bagging; On the bottom of the conveyor belt 2, there is also a load cell 4, which is electrically connected to the motor that controls the operation of the conveyor belt 2. When the load cell 4 senses that the packaging bag reaches the set weight, the load cell 4 sends a signal Pass to the motor that controls conveyor belt 2 to run, and the motor that controls conveyor belt 2 to run starts to make conveyor belt 2 run, and the industrial starch after bagging is transported on the transport crawler 8. The transport track 8 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com