High purity soybean oligopeptide having unique solubility and preparation method and application

A soybean oligopeptide, high-purity technology, applied in the field of deep processing of soybean protein, can solve the problems of strong hygroscopicity, poor sensory perception, and insignificant efficacy, so as to improve product yield, ensure high efficiency, and compact preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

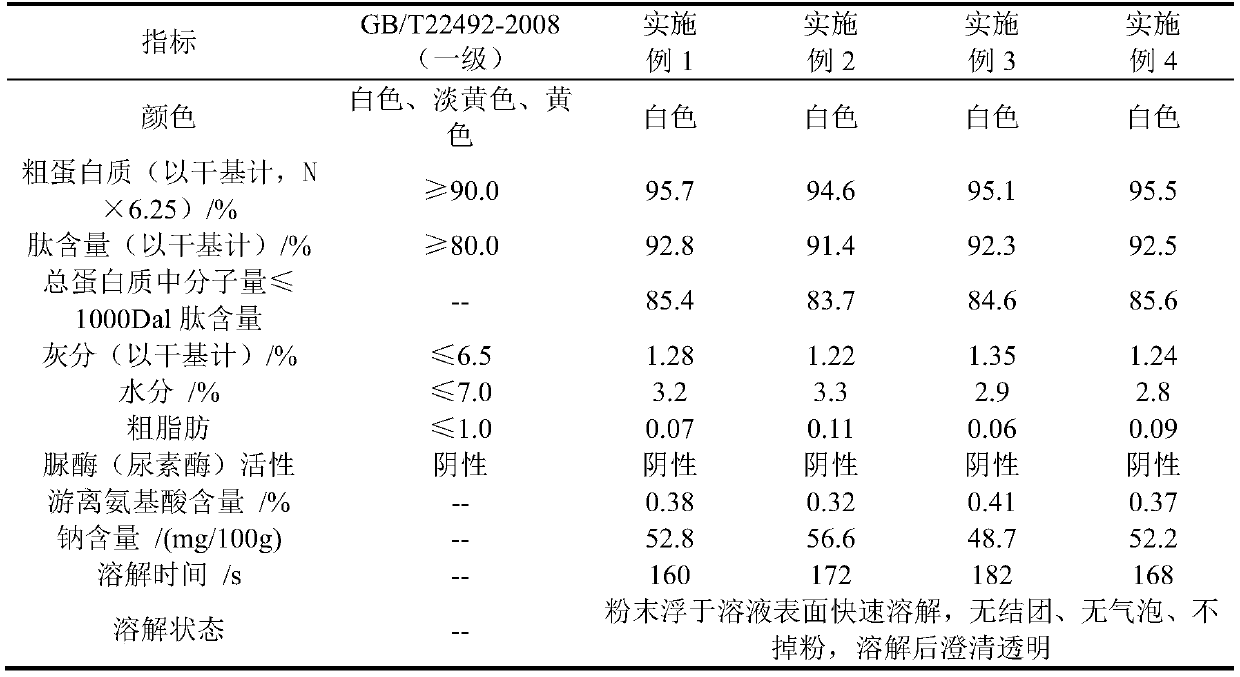

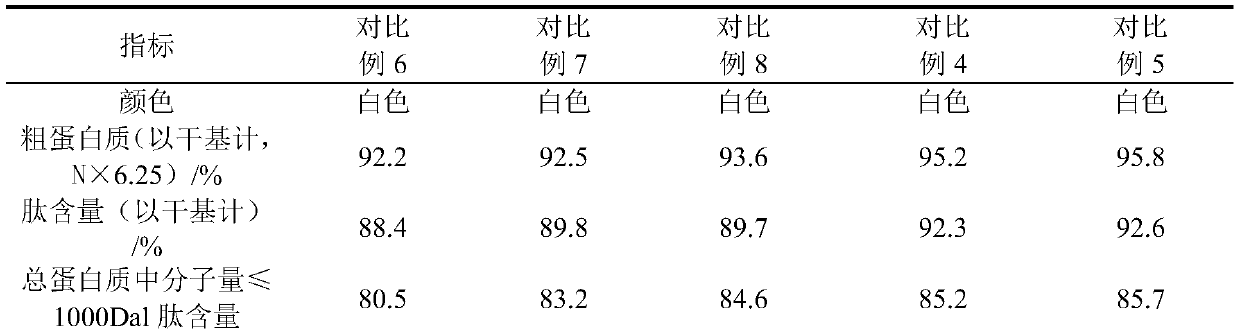

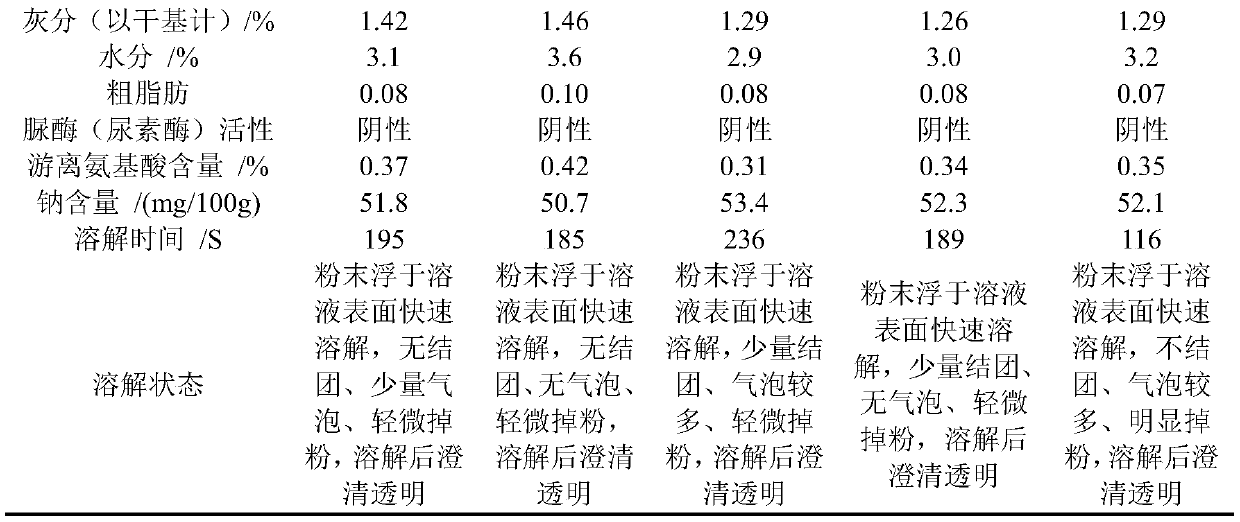

Examples

Embodiment 1

[0056] (1) Dispersion and hydration of soybean protein isolate powder: use deionized water to prepare soybean protein isolate powder into a protein slurry with a mass percentage of 10%, and use a mixer to shear, disperse, and hydrate the soybean protein powder at a speed of 2500 rpm 15min;

[0057] (2) Enzymolysis: Use a sodium hydroxide solution with a concentration of 3 mol / L to adjust the pH value of the protein slurry to 9.0, and add Alcalase 2.4L (commercial enzyme from Novozymes Biotechnology Co., Ltd.) equivalent to 1.0% of the protein powder mass in the Stir at 53°C (stirring speed is 36rpm) and hydrolyze for 6.5h, then add Neutrase 0.8L (commercial enzyme from Novozymes Biotechnology Co., Ltd.) equivalent to 0.6% of protein powder mass, and medium temperature 480L type α - Amylase (commercial enzyme from Novozymes Biotechnology Co., Ltd.), stirred and hydrolyzed at 53°C for 1.5h;

[0058] (3) Decolorization by adsorption of enzyme and activated carbon: after enzymoly...

Embodiment 2

[0063] (1) Dispersion and hydration of soybean protein isolate powder: use deionized water to prepare soybean protein isolate powder into a protein slurry with a mass percentage of 5%, and use a mixer to shear and disperse the soybean protein powder evenly and hydrate at a speed of 2000rpm 20min;

[0064] (2) Enzymolysis: Use a sodium hydroxide solution with a concentration of 1 mol / L to adjust the pH value of the protein slurry to 8.0, add Alcalase 2.4L (a commercial enzyme from Novozymes Biotechnology Co., Ltd.) equivalent to 0.5% of the protein powder mass in the Stir at 50°C (stirring speed is 36rpm) and hydrolyze for 10h, then add Neutrase 0.8L (commercial enzyme from Novozymes Biotechnology Co., Ltd.) equivalent to 0.2% of protein powder mass, and medium-temperature 480L type α- Amylase (commercial enzyme from Novozymes Biotechnology Co., Ltd.) was stirred and hydrolyzed at 50°C for 2h;

[0065] (3) Decolorization by adsorption of enzyme and activated carbon: After enzy...

Embodiment 3

[0070] (1) Dispersion and hydration of soybean protein isolate powder: use deionized water to prepare soybean protein isolate powder into a protein slurry with a mass percentage of 15%, and use a mixer to shear, disperse, and hydrate the soybean protein powder at a speed of 3000 rpm 10min;

[0071] (2) Enzymolysis: Use a sodium hydroxide solution with a concentration of 5 mol / L to adjust the pH value of the protein slurry to 10.0, add Alcalase 2.4L (commercial enzyme from Novozymes Biotechnology Co., Ltd.) equivalent to 1.0% of the protein powder mass in the Stir at 55°C (stirring speed is 36rpm) and hydrolyze for 3h, then add Neutrase 0.8L (commercial enzyme from Novozymes Biotechnology Co. Xin Biotechnology Co., Ltd. commercial enzyme) was stirred and hydrolyzed at 55 ° C for 1 h;

[0072] (3) Decolorization of enzyme and activated carbon adsorption: after enzymolysis, heat up to 95°C, add 15% activated carbon powder (above 200 mesh) relative to the mass of soybean protein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com