Disc diaphragm aerator

A kind of aerator and membrane technology, applied in the field of aerator, to achieve the effect of reducing friction, reducing aeration resistance, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

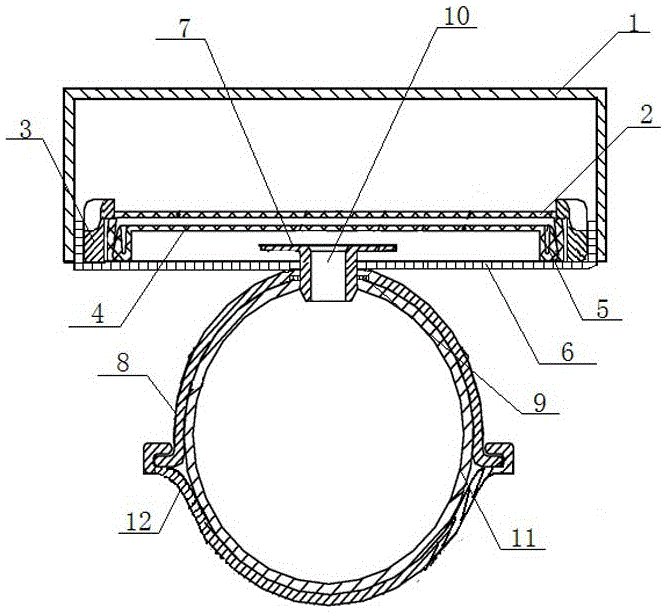

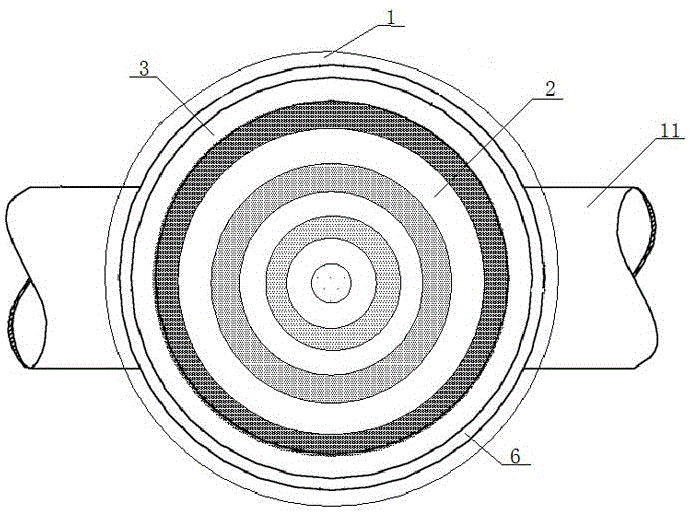

[0031] A disc type membrane aerator provided in this embodiment has a structure such as figure 1 and figure 2As shown, it includes a screw gland 3, a diaphragm 2, and a base. The diaphragm 2 is arranged between the screw gland 3 and the base, and a diversion supporting plate 4 for supporting the diaphragm 2 is also provided between the diaphragm 2 and the base. , the surrounding edges of the diversion support plate 4 are uniformly provided with through holes 5, and a check valve 7 with a hole and a valve integrated is arranged between the diversion support plate 4 and the base. The base is provided with a filter cover 1, and the bottom of the base An inverted saddle-shaped wedge plate 12 is also provided, wherein: the diaphragm 2 is provided with a plurality of openings, and the openings are strip-shaped micro-holes; the base is composed of a cylindrical chassis 6 with an open upper end and a saddle-shaped support 8. There are holes on the saddle-shaped bracket 8, and the ch...

Embodiment 2

[0039] The structure of this embodiment is the same as that of Embodiment 1, and the difference is that in the disc type diaphragm aerator of this embodiment, the materials of the diaphragm, the check valve and the O-shaped sealing ring are all composite polypropylene materials, including polypropylene Matrix and reinforcement system, the components in parts by weight of the polypropylene matrix include: polypropylene resin: 86 parts, 3-hydroxypropionitrile: 6 parts, o-methylhydroquinone: 0.8 parts, nucleating agent: 1.7 parts , Antioxidant: 2.2 parts, Lubricant: 0.3 parts, Filler: 7.6 parts; The addition amount of reinforcement system is 6.5% of polypropylene matrix weight; : 13.8 parts, ethoxylated alkylamine: 36 parts, methyl hydrogen silicone oil: 72 parts, ammonium polyphosphate: 1.6 parts, chopped glass fiber: 5.8 parts, fumed silica: 3.6 parts, γ- Aminopropyltriethoxysilane: 4 parts, toughening agent: 2.8 parts, reactive diluent: 2.6 parts, compatibilizer: 1.6 parts, co...

Embodiment 3

[0041] The structure of this embodiment is the same as that of Embodiment 1, and the difference is that in the disc type diaphragm aerator of this embodiment, the materials of the diaphragm, the check valve and the O-shaped sealing ring are all composite polypropylene materials, including polypropylene Matrix and reinforcement system, the components in parts by weight of the polypropylene matrix include: polypropylene resin: 87 parts, 3-hydroxypropionitrile: 7 parts, o-methylhydroquinone: 0.9 parts, nucleating agent: 1.8 parts , Antioxidant: 2.3 parts, lubricant: 0.4 parts, filler: 7.7 parts; the addition of reinforcement system is 7% of the weight of polypropylene matrix; the components of reinforcement system are composed of nano-silica : 13.9 parts, ethoxylated alkylamine: 37 parts, methyl hydrogen silicone oil: 73 parts, ammonium polyphosphate: 1.7 parts, chopped glass fiber: 5.9 parts, fumed silica: 3.7 parts, γ- Aminopropyl triethoxysilane: 5 parts, toughening agent: 2.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com