Environment-friendly recycled asphalt mixture and preparation technology thereof

A technology of recycled asphalt and preparation process, which is applied in the field of asphalt, which can solve the problems of waste of resources, damage to the ecological environment, pollution of the environment, etc., and achieve the effect of saving energy and alleviating the shortage of supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

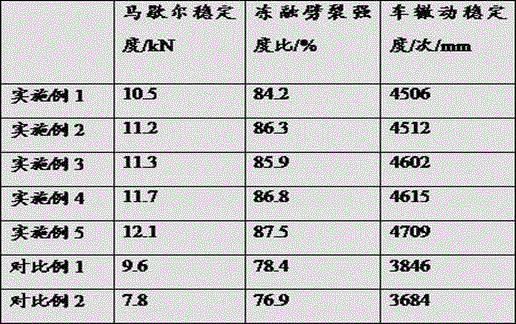

Examples

Embodiment 1

[0023] An environmentally friendly recycled asphalt mixture, which is composed of the following components in parts by weight: 10 parts of waste asphalt, 3 parts of biological asphalt, 1 part of modified asphalt, 1 part of 40 mesh waste tire powder, 55 parts of aggregate, 5 parts of mineral powder, 2 parts of environmentally friendly solvent oil, 1 part of orange oil, 1.5 parts of coumarone, 2.5 parts of smectite, 4 parts of silver-loaded zeolite, 5 parts of lime, 1.6 parts of tin dioxide, isocyanate propyl triethyl 0.6 parts of oxysilane, 1.2 parts of polyoxyethylene ether, 0.3 parts of glycerol phosphate, 3.2 parts of regeneration agent, 0.4 parts of sodium silicate;

[0024] The modified asphalt is a natural rubber modified asphalt;

[0025] The aggregate is a mixture of granite, basalt and quartz with a particle size of 0.1-10mm and a mass ratio of 5:1:2;

[0026] The mineral powder is calcium carbonate powder with a particle size smaller than 0.05mm.

[0027] Wherein, d...

Embodiment 2

[0034] An environmentally friendly recycled asphalt mixture, which consists of the following components in parts by weight: 20 parts of waste asphalt, 7 parts of biological asphalt, 4 parts of modified asphalt, 6 parts of 40 mesh waste tire powder, 70 parts of aggregate, 13 parts of mineral powder, 4 parts of environmentally friendly solvent oil, 3 parts of orange oil, 3 parts of coumarone, 6 parts of smectite, 7 parts of silver-loaded zeolite, 9 parts of lime, 4 parts of tin dioxide, isocyanate propyl triethyl 2.6 parts of oxysilane, 3.6 parts of polyoxyethylene ether, 2 parts of glycerol phosphate, 6 parts of regeneration agent, 1.5 parts of sodium silicate;

[0035] Described modified asphalt comprises SBS modified asphalt and styrene-butadiene rubber modified asphalt that weight ratio is 1:3;

[0036] The aggregate is a mixture of granite, basalt and quartz with a particle size of 0.1-10mm and a mass ratio of 5:1:2;

Embodiment 3

[0045] An environmentally friendly recycled asphalt mixture, which consists of the following components in parts by weight: 12 parts of waste asphalt material, 3.5 parts of biological asphalt, 1.2 parts of modified asphalt, 1.8 parts of 40 mesh waste tire powder, 58 parts of aggregate, 5.7 parts of mineral powder, 2.2 parts of environmentally friendly solvent oil, 1.5 parts of orange oil, 1.8 parts of coumarone, 2.9 parts of smectite, 4.3 parts of silver-loaded zeolite, 5.3 parts of lime, 1.7 parts of tin dioxide, isocyanatopropyl triethyl 0.8 parts of oxysilane, 1.4 parts of polyoxyethylene ether, 0.6 parts of glycerol phosphate, 3.7 parts of regeneration agent, 0.8 parts of sodium silicate;

[0046] Described modified bitumen comprises the styrene-butadiene rubber modified bitumen and butadiene rubber modified bitumen that weight ratio is 4:1;

[0047] The aggregate is a mixture of granite, basalt and quartz with a particle size of 0.1-10mm and a mass ratio of 5:1:2;

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Marshall stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com