Large-steric-hindrance neutral nickel catalyst, preparation method and application in preparation of ethylene/polar monomer copolymers

A nickel catalyst and catalyst technology are applied in the application field of large sterically hindered neutral nickel catalyst and preparation, and the preparation of ethylene/polar monomer copolymer, and the effect of simple and efficient synthesis method is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

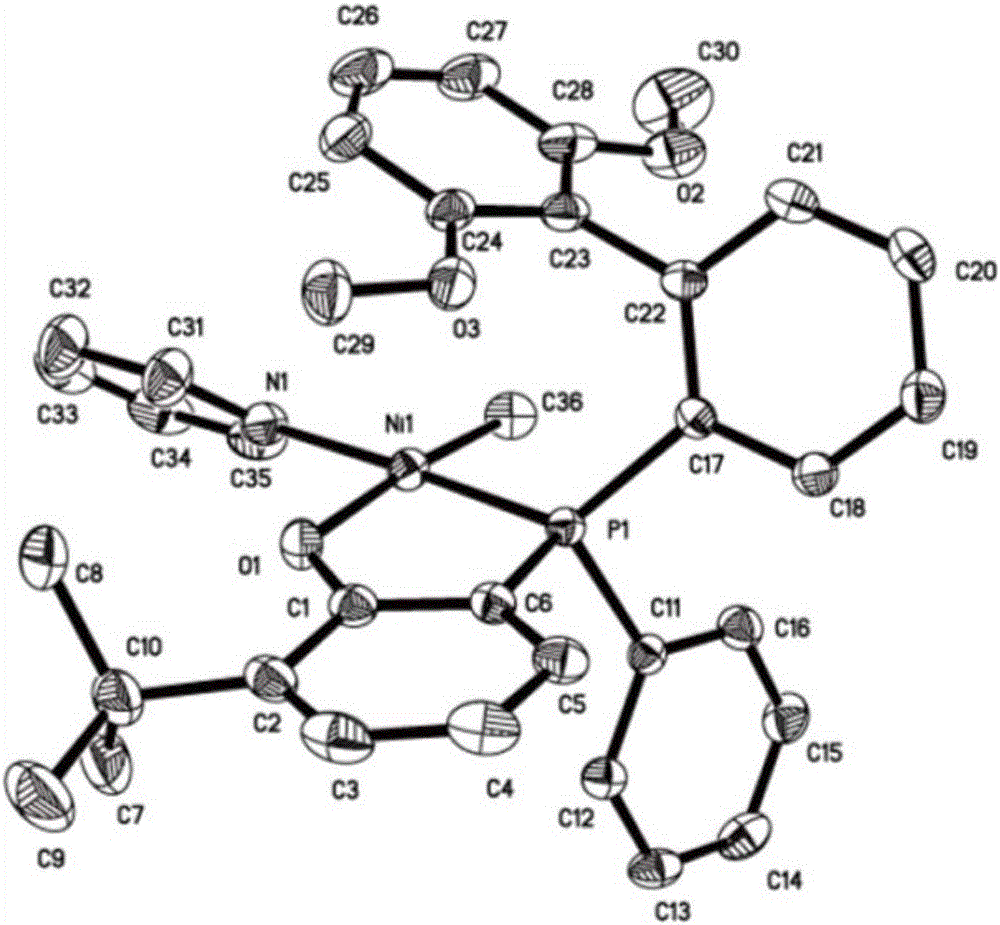

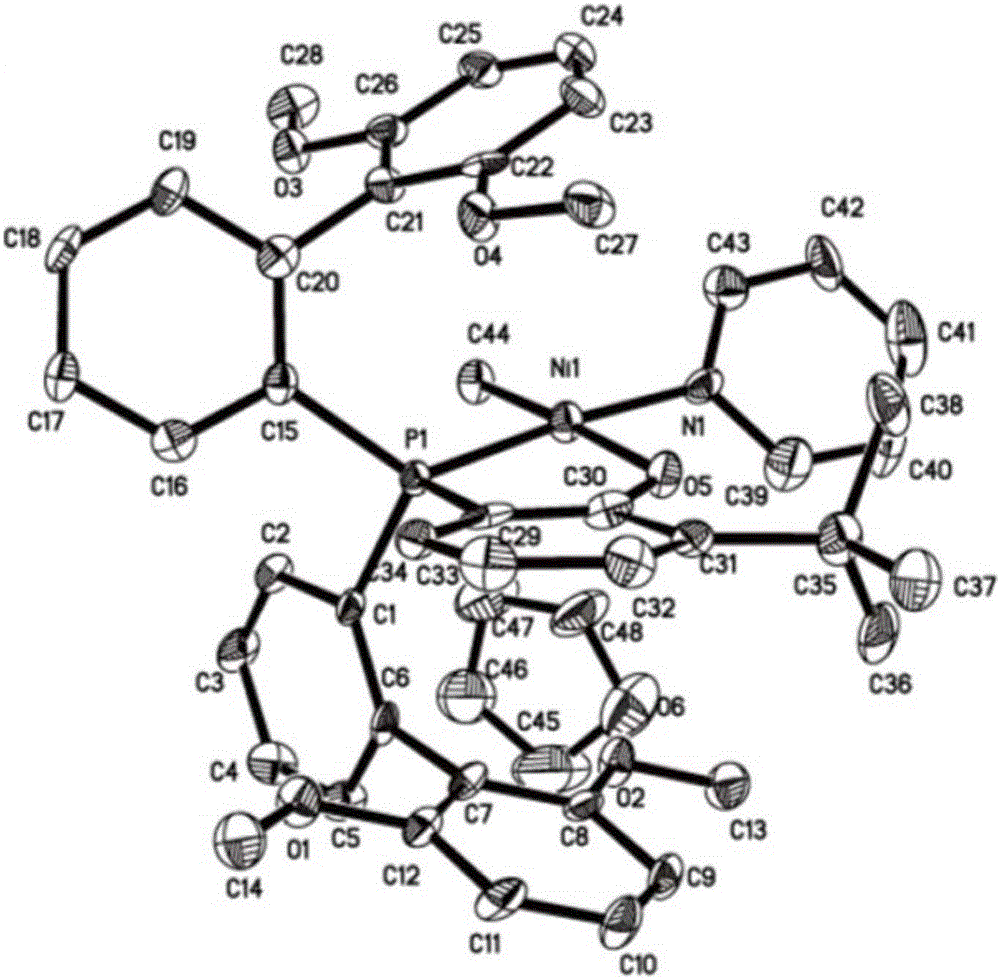

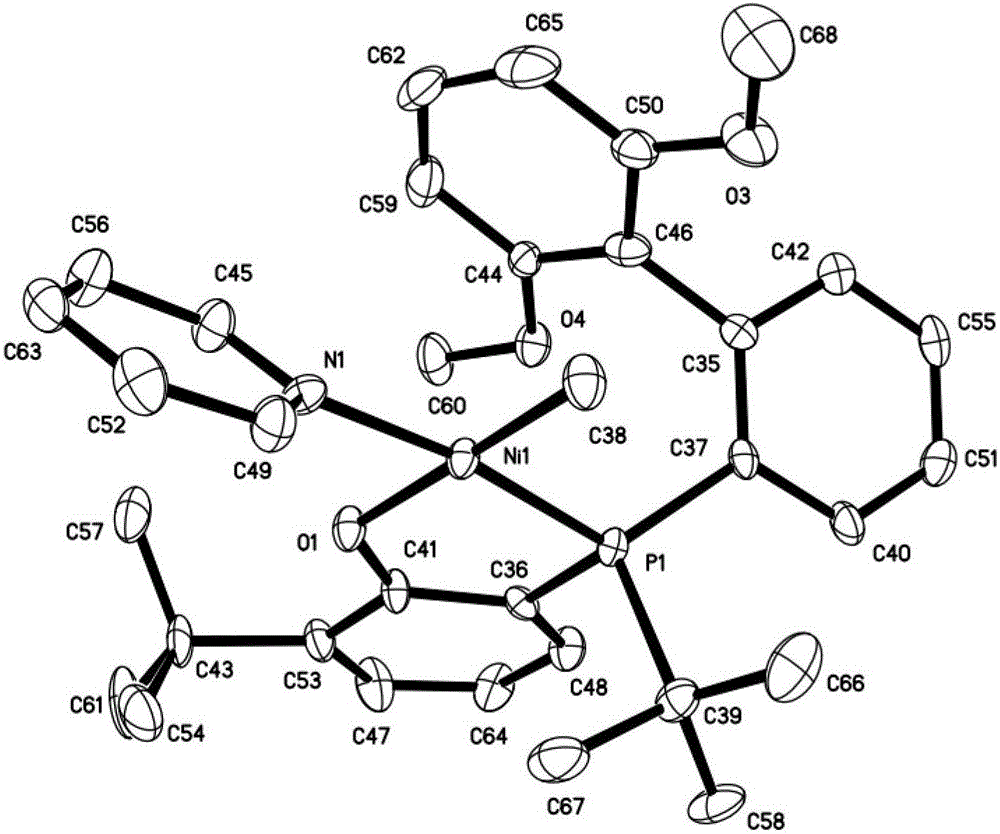

[0061] The invention provides a method for synthesizing a phenol-phosphine neutral nickel catalyst with a large hindered phosphine, by combining a phenol-phosphine ligand with Py 2 NiMe 2 Mix directly, remove the nickel black produced by the deterioration of the nickel source during the reaction after the reaction, and then obtain the catalyst with the structure of formula a~j, and the operation is simple. X-ray single crystal diffraction shows that the complex has a planar tetragonal structure centered on nickel.

[0062]

[0063] The Ar group is 2-(2',6'-(OMe) 2 -C 6 h 3 )-C 6 h 4 ;

[0064] Preferably, the nickel source required for the reaction is Py 2 NiMe 2 ;

[0065] Preferably, the reaction solvent is toluene, and the reaction temperature is room temperature.

[0066] The specific implementation steps of the catalyst with formula a~j structure synthesized by this example:

[0067] The specific implementation steps of this example are firstly the synthesis...

Embodiment 2

[0113] The polyethylene in this embodiment is linear polyethylene. The catalyst used is a catalyst having a structure of formula a.

[0114]

[0115] The Ar group is 2-(2',6'-(OMe) 2 -C 6 h 3 )-C 6 h 4 ;

[0116] The preparation method of linear polyethylene in the present embodiment comprises the following steps:

[0117] (1) Under high vacuum, add 500mL toluene into a dry 1000mL autoclave, stir for 5 minutes, the reaction temperature is stabilized to 70°C, add 10μmol of toluene solution of the catalyst having the structure of formula a, and quickly feed 10atm ethylene Gas, polymerization under strong stirring for 20 minutes;

[0118] (2) After the polymerization, the ethylene gas in the autoclave was evacuated, and the polymer obtained in the autoclave was poured into 1L of ethanol to settle. Then filter, wash and vacuum dry to obtain high molecular weight linear polyethylene.

[0119] The product obtained above was subjected to DSC analysis and NMR analysis, and...

Embodiment 3

[0121] The polyethylene in this embodiment is linear polyethylene, and the catalyst used is a catalyst having the structure of formula c.

[0122]

[0123] The Ar group is 2-(2',6'-(OMe) 2 -C 6 h 3 )-C 6 h 4 ;

[0124] The preparation method of linear polyethylene in the present embodiment comprises the following steps:

[0125] (1) Under high vacuum, add 500mL of toluene to a dry 1000mL autoclave, stir for 5 minutes, the reaction temperature stabilizes to 30°C, add 10μmol of toluene solution of the catalyst having the structure of formula c, and quickly pass into 10atm ethylene Gas, polymerization under strong stirring for 20 minutes;

[0126] (2) After the polymerization, the ethylene gas in the autoclave was evacuated, and the polymer obtained in the autoclave was poured into 1L of ethanol to settle. Then filter, wash and vacuum dry to obtain high molecular weight linear polyethylene.

[0127] The product obtained above was subjected to DSC analysis and nuclear m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com