Liquid state deslagging and graded gasifying reaction furnace of constant pressure fixed bed of water cooling wall

A technology of liquid slag discharge and gasification reaction, applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of molten slag level control and difficulty in slag discharge, and improve space utilization and energy utilization efficiency , the effect of reducing energy consumption and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

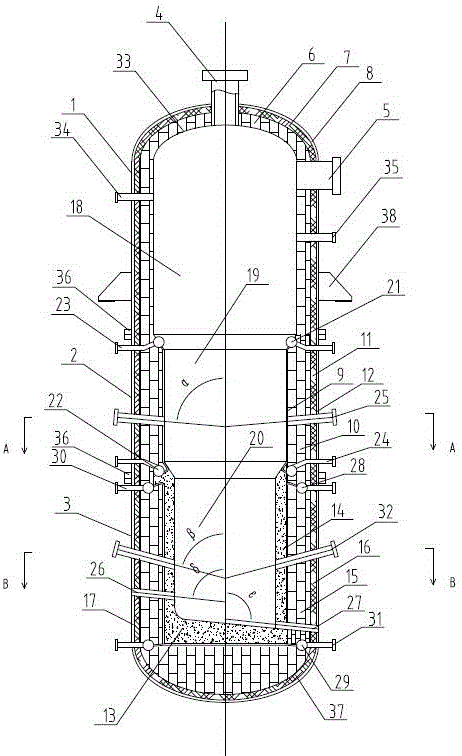

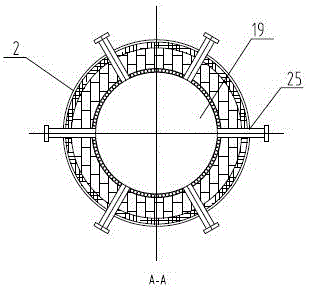

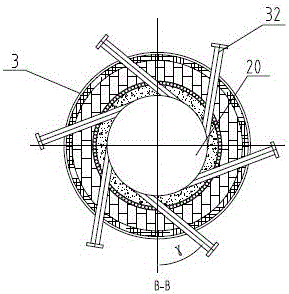

[0053] A water-cooled wall atmospheric pressure fixed bed liquid slagging graded gasification reaction furnace, comprising an upper furnace body 1, a middle furnace body 2 and a lower furnace body 3, forming a three-stage furnace structure; the top of the upper furnace body 1 is provided with The feed port 4 is provided with a synthesis gas outlet 5 on the side, and the side of the lower furnace body 3 is provided with a slagging outlet; The furnace body insulation layer 7 and the upper furnace body steel plate shell 8, the furnace wall of the middle furnace body 2 is the middle furnace body water-cooled wall layer 9, the middle furnace body refractory material layer 10, and the middle furnace body insulation layer 11 from the inside to the outside. And the steel plate shell 12 of the middle furnace body, the furnace wall of the lower furnace body 3 is successively composed of a refractory protective lining layer 13, a water-cooled wall layer 14 of the lower furnace body, a ref...

Embodiment 2

[0055] A water-cooled wall atmospheric pressure fixed bed liquid slagging graded gasification reaction furnace, comprising an upper furnace body 1, a middle furnace body 2 and a lower furnace body 3, forming a three-stage furnace structure; the top of the upper furnace body 1 is provided with The feed port 4 is provided with a synthesis gas outlet 5 on the side, and the side of the lower furnace body 3 is provided with a slagging outlet; The furnace body insulation layer 7 and the upper furnace body steel plate shell 8, the furnace wall of the middle furnace body 2 is the middle furnace body water-cooled wall layer 9, the middle furnace body refractory material layer 10, and the middle furnace body insulation layer 11 from the inside to the outside. And the steel plate shell 12 of the middle furnace body, the furnace wall of the lower furnace body 3 is successively composed of a refractory protective lining layer 13, a water-cooled wall layer 14 of the lower furnace body, a ref...

Embodiment 3

[0058] A water-cooled wall atmospheric pressure fixed bed liquid slagging graded gasification reaction furnace, comprising an upper furnace body 1, a middle furnace body 2 and a lower furnace body 3, forming a three-stage furnace structure; the top of the upper furnace body 1 is provided with The feed port 4 is provided with a synthesis gas outlet 5 on the side, and the side of the lower furnace body 3 is provided with a slagging outlet; The furnace body insulation layer 7 and the upper furnace body steel plate shell 8, the furnace wall of the middle furnace body 2 is the middle furnace body water-cooled wall layer 9, the middle furnace body refractory material layer 10, and the middle furnace body insulation layer 11 from the inside to the outside. And the steel plate shell 12 of the middle furnace body, the furnace wall of the lower furnace body 3 is successively composed of a refractory protective lining layer 13, a water-cooled wall layer 14 of the lower furnace body, a ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com