Biomass fertilizer preparation method and system therefor

A preparation system and biomass technology, applied in the field of biomass fertilizer preparation, can solve the problems of large energy loss, environmental pollution, high carbon loss rate, etc., and achieve the effect of improving the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

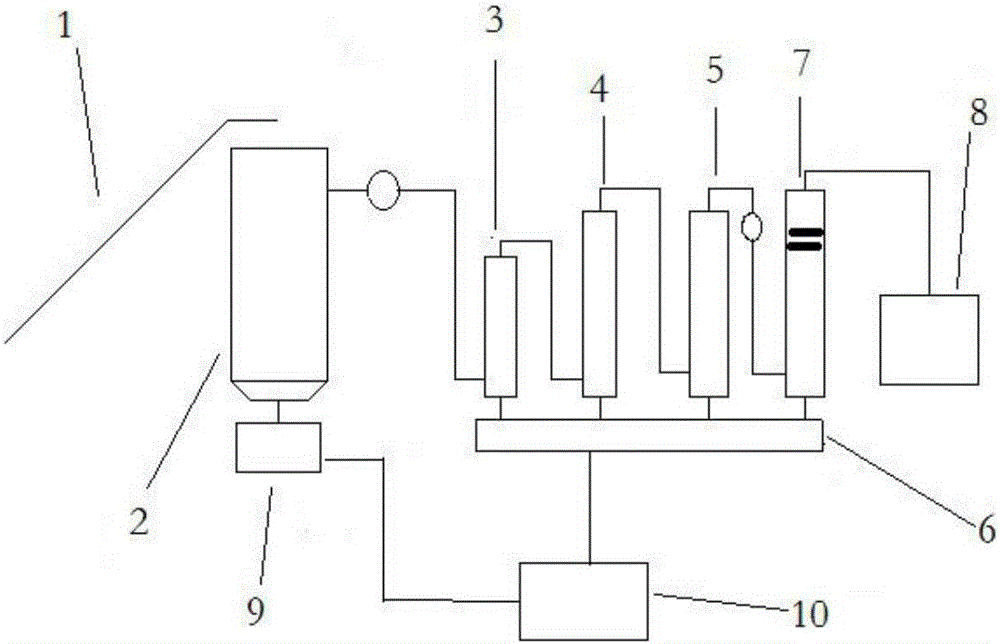

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] A preparation method of biomass fertilizer, comprising the following steps:

[0027] a) The biomass is transported to the gasification furnace 2 by the raw material conveyor 1 and pyrolyzed into combustible gas and activated carbon, and the activated carbon is collected in the carbon storage bin 9 of the gasification furnace 2;

[0028] b) Turn on the induced draft fan to transport the flammable gas to the spray tower 3, scrubber 4 and condensation tower 5 successively to remove dust, tar, organic acid and moisture in the gas, and cool down to 25°C-30°C , the condensed solution is circulated to the reservoir 6;

[0029] e) continue to transport to the decoking and dedusting tower 7 to further remove tar, org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com