Preparation method for wet copper slag formed pellets

A technology of pelletizing and copper slag, which is applied in the field of preparation of wet copper slag forming pellets, can solve problems such as environmental pollution and waste of resources, and achieve the effects of simple industrial operation, low production cost, and low energy consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

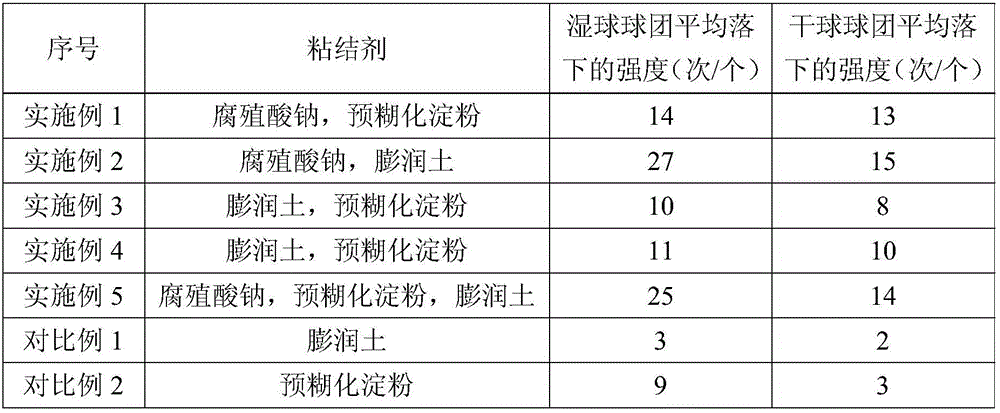

Examples

preparation example Construction

[0029] The invention provides a method for preparing wet copper molding pellets. The method comprises the following steps: taking copper slag powder as a benchmark, and by mass percentage, copper slag powder, carbon raw material, and limestone in a mass ratio of 100: (20 ~25): (16~20) are mixed to obtain a mixed material; a composite binder is added to the obtained mixed material, and the composite binder and copper slag powder are carried out according to the mass ratio of (2~6):100 Mix and mix evenly to obtain a composite material, put the obtained composite material into a disc pelletizer for pelletizing to obtain wet pellets, dry or dry the obtained wet pellets to obtain dry pellets group.

[0030] In the above method, the carbon raw material adopts coal powder or blue charcoal powder.

[0031] In the above method, the content of total iron (TFe) in the copper slag powder is 35%-45%, and the carbon content in the carbon raw material is 65%-85%.

[0032] In the above meth...

Embodiment 1

[0045] Preparation of composite binder:

[0046] In this embodiment, the composite binder includes raw materials according to the following mass percentage proportioning:

[0047] Sodium humate 80%, pregelatinized starch 20%;

[0048] Weigh 32g of sodium humate and 8g of pregelatinized starch, put them into a mixer and stir to obtain a composite binder.

[0049] The method for preparing wet copper slag molding pellets by using the above-mentioned composite binder is as follows:

[0050] Mix 1000g of copper slag powder with a total iron content of 35% and a moisture content of 10.5%, 250g of coal powder with a carbon content of 65% and a moisture content of 8%, and 160g of limestone with a moisture content of 1.8%, and stir for 10 minutes to obtain a mixed material . The obtained mixed material was further mixed with 40 g of the composite binder prepared above, and stirred for 5 minutes to obtain a composite material. Put the obtained composite material into a disc pelletiz...

Embodiment 2

[0053] Preparation of composite binder:

[0054] In this embodiment, the composite binder includes raw materials according to the following mass percentage proportioning:

[0055] Sodium humate 20%, bentonite 80%;

[0056] Take by weighing 12g of sodium humate and 48g of bentonite, put them into a mixer and stir and mix to obtain a composite binder.

[0057] The method for preparing wet copper slag molding pellets by using the above-mentioned composite binder is as follows:

[0058] Mix 1000g of copper slag powder with a total iron content of 40% and a moisture content of 10%, 210g of blue charcoal powder with a carbon content of 70% and a moisture content of 9.5%, and 170g of limestone with a moisture content of 1.5%, and stir for 8 minutes to obtain a mixture material. The obtained mixed material was further mixed with 60 g of the composite binder prepared above, and stirred for 10 minutes to obtain a composite material. Put the obtained composite material into a disc pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com