Method for recycling zinc from zinc-contained resources through synchronous flotation-sulfation roasting

A sulfation roasting and resource technology, which is applied in flotation, process efficiency improvement, solid separation and other directions, can solve the problems of non-ferrous metal oxide ore and mixed ore sorting, and no engineering beneficiation technology has been formed, and achieve recovery rate. High, less pollution, the effect of processing a wide range of zinc resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

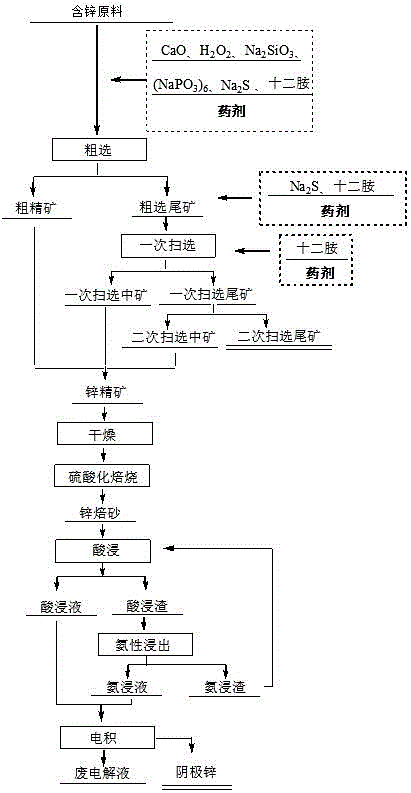

[0021] Embodiment 1: as figure 1 Shown, this zinc-containing resource synchronous flotation-sulfation roasting reclaims the method for zinc, and its concrete steps are as follows:

[0022] (1) Crushing and finely grinding the sphalerite, in which the sphalerite with a particle size of less than 200 meshes accounts for 60% of the total sphalerite quality, and roughing agents (1kg / t CaO, 300g / t H 2 o 2 , 400g / t Na 2 SiO 3 , 400g / t (NaPO 3 ) 6 kg / t, 2kg / t Na 2 S, 200g / t dodecylamine) was added to sphalerite and roughed for 5 minutes to obtain rough concentrate and roughed tailings; the scavenging agent (2 kg / tNa 2 S, 50 g / t dodecylamine) is added to the roughing tailings for the first scavenging for 2 minutes to obtain a scavenging medium and a scavenging tailings; add a scavenging agent (50 g / t dodecylamine) to a scavenging Carry out the second scavenging of the tailings for 2 minutes to obtain the secondary scavenging and secondary scavenging tailings; combine the coarse...

Embodiment 2

[0028] Embodiment 2: as figure 1 Shown, this zinc-containing resource synchronous flotation-sulfation roasting reclaims the method for zinc, and its concrete steps are as follows:

[0029] (1) Crushing smithsonite, in which smithsonite with a particle size of less than 180 mesh accounts for 70% of the total smithsonite mass, roughing agents (1.5kg / t CaO, 400g / t H 2 o 2 , 500g / t Na 2 SiO 3 , 500g / t (NaPO 3 ) 6 , 8kg / t Na 2 S, 400g / t dodecylamine) was added to smithsonite for roughing for 6 minutes to obtain rough concentrate and roughing tailings; the scavenging agent (6kg / t Na 2 S, 80g / t dodecylamine) is added to the roughing tailings for the first scavenging for 4 minutes to obtain a scavenging medium and a scavenging tailing; add a scavenging agent (70g / t dodecylamine) to a scavenging tail The ore is swept for the second time for 4 minutes to obtain the secondary scavenging and tailings; combine the coarse concentrate, the first scavenging and the second scavenging to...

Embodiment 3

[0035] Embodiment 3: as figure 1 Shown, this zinc-containing resource synchronous flotation-sulfation roasting reclaims the method for zinc, and its concrete steps are as follows:

[0036] (1) The low-grade zinc oxide ore is crushed and finely ground, among which the zinc oxide ore with a particle size of less than 160 mesh accounts for 80% of the total zinc oxide ore quality, and the roughing agent (2kg / t CaO, 600g / t H 2 o 2 、600g / t Na 2 SiO 3 , 600g / t (NaPO 3 ) 6 , 10kg / t Na 2 S, 600g / t dodecylamine) was added to zinc oxide ore and roughed for 8 minutes to obtain rough concentrate and roughed tailings; the scavenging agent (10kg / t Na 2 S, 150g / t dodecylamine) was added to the roughing tailings for the first scavenging for 5 minutes to obtain a scavenging medium ore and a scavenging tailing; add a scavenging agent (100g / t dodecylamine) to a scavenging tail The ore is scavenged for the second time for 5 minutes to obtain the secondary scavenging and tailings; combine th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com