Production process for long-length high-strength and high-conductivity copper-chrome-zirconium alloy contact wire

A production process, copper chromium zirconium technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of length, weight and shape limitations, high vacuum production cost, difficult production scale, etc., to reduce cost and difficulty , the distribution of alloy components is uniform, and the effect is consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

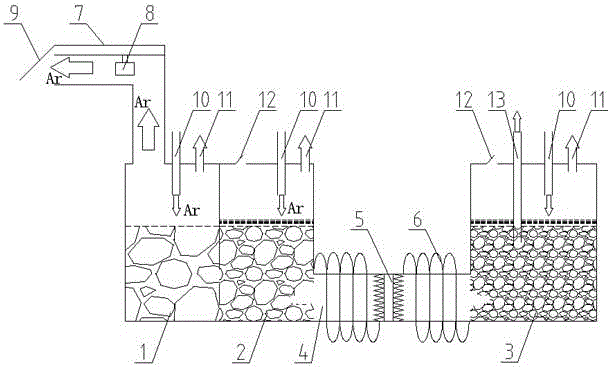

[0121] like Figure 5As shown, the right-angle channel continuous extrusion device includes a first extrusion die 27, and the first extrusion die 27 includes a first extrusion cavity 30, and the front side of the first extrusion cavity 30 is provided with a first A feeding channel 28, the first punching channel 31, the second punching channel 32 and the third punching channel 33 are arranged above the first extrusion cavity 30, the first punching channel 31, the second punching channel 32 and the Each of the third punches 33 is provided with corresponding punches, the first punches 31 are arranged vertically, and the second punches 32 and the third punches 33 are symmetrically arranged on the first punches. 31 on both sides, the first punching channel 31 is two volumes, the second punching channel 32 and the third punching channel 33 are one volume, and the second punching channel 32 and the third punching channel 33 form a 120° clip Angle, a right-angle discharge channel 29 ...

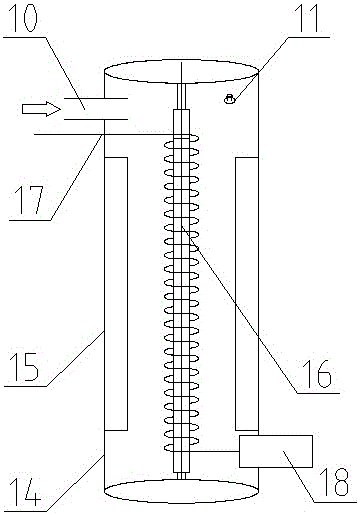

Embodiment 2

[0126] like Figure 6~Figure 9 As shown, the continuous extrusion device for right-angle passages includes a second extrusion die 35, and the second extrusion die 35 includes a second extrusion cavity 36, and the front side of the second extrusion cavity 36 is provided with a first Two feeding passages 37 and four feeding pressurizing passages 42 up, down, left, and right. Each feeding pressurizing passage 42 is provided with a corresponding punch. The rear side of the second extrusion cavity 36 is provided with a center outlet The material channel 38, the second feed channel 37 and the central discharge channel 38 are located on the same center line as the second extrusion cavity 36, and the four feed pressurization channels 42 are connected to the center of the second extrusion cavity 36. The line is at a certain angle. The central discharge channel 38 includes two sections, the front and the rear. A reverse circulation cooling system 41 is provided on the outside of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com