High-strength and high-toughness cast rare earth magnesium alloy and preparation method thereof

A high-strength, high-toughness, rare-earth magnesium technology, applied in the field of light metal materials, can solve the problems of poor toughness, low strength of magnesium alloys, and poor heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing a high-strength and high-toughness casting rare earth magnesium alloy, comprising the following steps:

[0045] Step 1. Proportioning the magnesium source, zinc source, ytterbium source and zirconium source according to the mass percentage of each component, removing the scale on the surface of the raw materials of each component and preheating to 200-300°C;

[0046] According to the present invention, the sources of the above-mentioned raw materials are not particularly limited, and they can be known sources in the field of rare earth magnesium alloy preparation. Generally, the source of magnesium is commercially available high-purity magnesium ingots, the source of zinc is high-purity zinc, and the source of ytterbium is ytterbium-15 % magnesium-ytterbium master alloy, zirconium is a magnesium-zirconium master alloy containing 30wt.% zirconium, and the mass percentage of magnesium is determined by high-purity m...

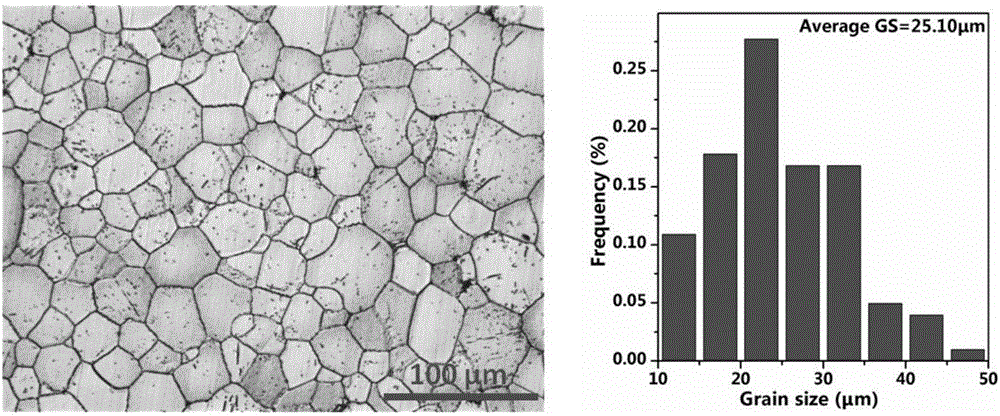

Embodiment 1

[0056] A high-strength and high-toughness casting Mg-Yb-Zn-Zr rare earth magnesium alloy, the mass percent of each component is: Yb 0.5%, Zn 0.4%, Zr 0.4%, and the balance is Mg and unavoidable impurity elements.

[0057] A method for preparing a high-strength and high-toughness casting Mg-Yb-Zn-Zr rare earth magnesium alloy, the steps are as follows:

[0058] Step 1. First, according to the composition of the Mg-Yb-Zn-Zr alloy and the mass percentage of each component, batching is carried out; the oxide skin on the surface of each component raw material is removed and preheated to 250°C;

[0059] Step 2. Preheat the iron tongs pot to 550°C, add high-purity magnesium ingots, set the furnace temperature to 720°C and feed SF 6 :CO 2 Protective gas with a volume ratio of 1:200;

[0060] Step 3. After the magnesium ingot is completely melted, when the measured melt temperature is 730°C, skim off the scum on the melt surface, add the above-mentioned pure zinc and magnesium-ytterb...

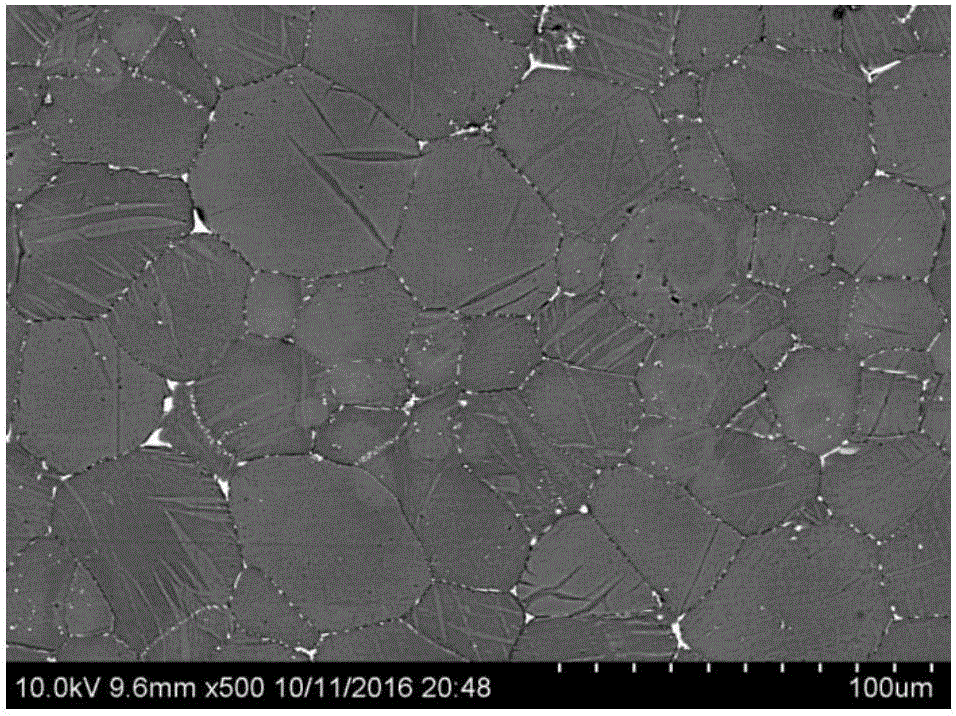

Embodiment 2

[0067] A high-strength and high-toughness casting Mg-Yb-Zn-Zr rare earth magnesium alloy, the mass percentage of each component is: Yb 1.0%, Zn 0.5%, Zr 0.5%, and the balance is Mg and unavoidable impurity elements.

[0068] A method for preparing a high-strength and high-toughness casting Mg-Yb-Zn-Zr rare earth magnesium alloy, the steps are as follows:

[0069] Step 1. First, according to the composition of the Mg-Yb-Zn-Zr alloy and the mass percentage of each component, batching is carried out; the oxide skin on the surface of each component raw material is removed and preheated to 250°C;

[0070] Step 2. Preheat the iron tongs pot to 550°C, add high-purity magnesium ingots, set the furnace temperature to 740°C and feed SF 6 :CO 2 Protective gas with a volume ratio of 1:200;

[0071] Step 3. After the magnesium ingot is completely melted, when the measured melt temperature is 740°C, skim off the scum on the surface of the melt, add the above-mentioned pure zinc and magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com