SCR denitration catalyst evaluation device

A denitrification catalyst and evaluation device technology, which is applied in the field of SCR denitrification catalyst evaluation device, can solve the problems of high test cost, dependence on manual operation, and long time, and achieve unattended automatic operation, easy disassembly and operation, The effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

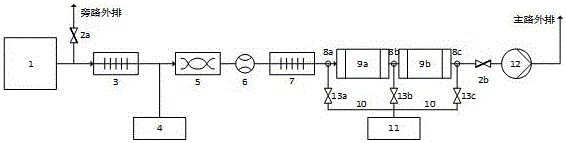

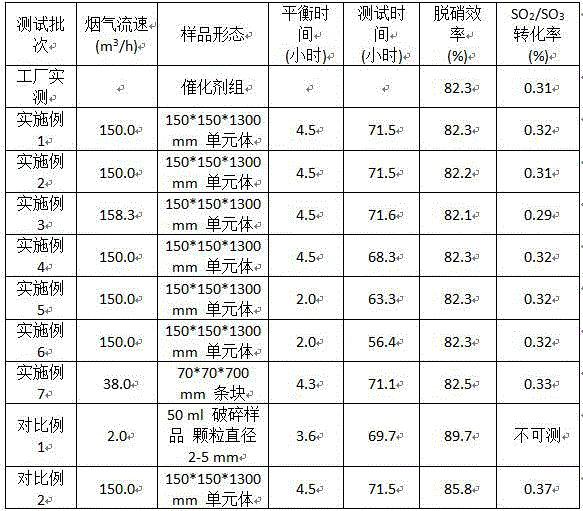

[0035] A kind of SCR denitration catalyst evaluation device of the present invention, flow process is as follows figure 1 shown. The oil-fired boiler (1) is used as the basic flue gas generating device, equipped with two-stage preheaters (3, 7) and two-stage reactors (9). The internal size of each reactor (9a, 9b) is 150*150*1500 mm, the front and rear of the reactor are sealed with graphite gaskets, and the front, middle, and rear are equipped with sampling pipelines (10) and online analysis systems (11 ) connection, the flue gas flow is measured by the flow meter (6), and forms a control loop with the flow regulating valve (2a) on the outlet bypass of the boiler (1) and the flow regulating valve (2b) on the outlet pipeline of the reactor. Reactor flue gas flow.

Embodiment 2

[0037] An SCR catalyst evaluation device of the present invention is different from Embodiment 1 in that a natural gas combustion furnace and a water removal device are used instead of an oil-fired boiler (1).

Embodiment 3

[0039] An SCR catalyst evaluation device of the present invention is different from Embodiment 1 in that the boiler outlet pipeline does not include a flue gas bypass pipe and a regulating valve (2a), and does not have the function of automatically adjusting the flue gas flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com