Water-in-oil analyzer calibration device and method

A technology of verification devices and analyzers, applied in measuring devices, analysis materials, instruments, etc., can solve the problems of high consumption of manpower and material resources, long test time, unsafe and environmental protection, etc., to reduce production costs, save test consumables, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

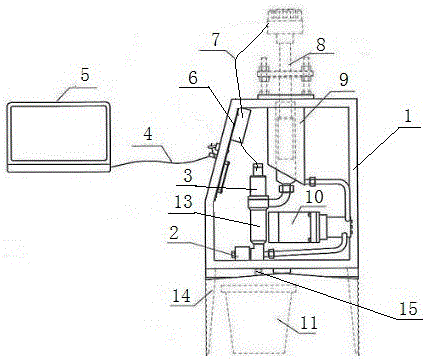

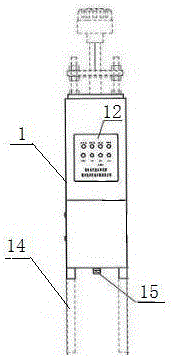

[0048] This embodiment provides a crude oil moisture analyzer testing device, combined with figure 1 and figure 2 As shown, it includes a box-type housing 1. The inside of the box-type housing 1 is equipped with a medium circulation system, a standard water content analyzer 3, a measured crude oil water content analyzer 8 and a data processing unit 6. The box-type housing 1 is provided with a panel 12. The standard water content analyzer 3 is embedded with a temperature sensor, which can detect the temperature in real time. The standard water content analyzer 3 and the measured crude oil water content analyzer 8 are respectively electrically connected to the data processing unit 6, and the data processing unit 6 is electrically connected to the panel 12, and the panel 12 Electrically connected to a host computer 5, the host computer 5 has a built-in microcomputer system program for the verification device of the water content analyzer in crude oil, and the microcomputer progr...

Embodiment 2

[0052] This embodiment is further improved. The four corners of the bottom plate of the box-type housing 1 are provided with folding brackets 14. The bottom plate of the box-type housing 1 has a slope structure from the four corners to the middle, and the folding bracket 14 is also a slope structure. The base plate slopes are complementary.

[0053] The medium circulation system is provided with a liquid discharge port 15, and a solenoid valve 2 is provided at the liquid discharge port 15. The liquid discharge port 15 runs through the bottom plate of the box-type housing 1, and an oil drum 11 is arranged under the bottom plate of the box-type housing 1. After the verification of the device is completed, the solenoid valve 2 can automatically discharge liquid, which is convenient, safe and environmentally friendly.

[0054] The foldable support 14 is used for placing the box-type housing 1 on site. After the foldable support 14 is opened, the oil drum 11 can be placed under the...

Embodiment 3

[0056] Above-mentioned data processing unit 6 comprises signal acquisition, processing, control circuit, is used for the acquisition of the detection signal of standard water content analyzer 3 and tested crude oil water content analyzer 8, processing and control transmission to panel 12, the signal acquisition involved here , processing, and control circuits are all existing mature circuits, which belong to the prior art, and are not specifically explained here; the panel 12 is provided with a solenoid valve switch indicator light, a gear pump indicator light, a power supply indicator light, and a start-stop solenoid valve. and gear pump buttons. This embodiment has the prompting function of the operation indicator light. During the verification process, the device can be operated according to the prompt of the operation indicator light, which is convenient for the operator.

[0057] The standard moisture analyzer 3 and the measured crude oil moisture analyzer 8 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com