A strong acid-resistant magnetic adsorption particle

A magnetic adsorption and magnetic particle technology, applied in the direction of adsorption of water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of acid resistance, secondary pollution, magnetic particles losing magnetism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

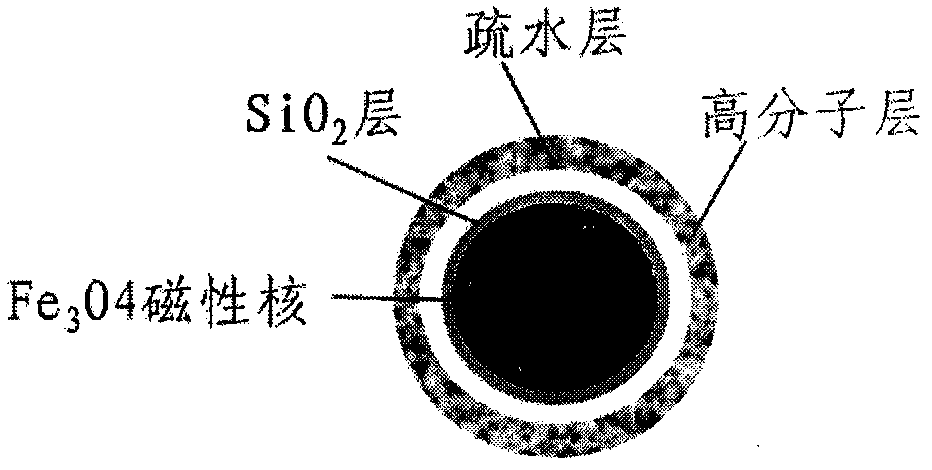

[0034] [Example 1] Fe 3 o 4 Synthesis

[0035] Synthesis of magnetic Fe according to literature 3 o 4 Particles, the specific operation is as follows: under the protection of inert gas, 7.05g FeCl 3 and 4.3g FeCl 2 4H 2 O was dissolved in 200 mL deionized water and heated to 85 °C. Add 40ml concentrated ammonia water and stir for 30min. Then use a magnet to attract sedimentation, and wash with deionized water several times until nearly neutral. Wash twice with ethanol, 100 mL each time. Drain the residual ethanol and dry to obtain micronanoscale Fe 3 o 4 .

Embodiment 2

[0036] [Example 2] Silicon oxide coated magnetic particles (Fe 3 o 4 @SiO 2 )

[0037] With 100mL ethanol with Fe in embodiment 1 3 o 4 The particles were dispersed in 25mL of water by ultrasonic treatment for 30min. Under mechanical stirring, a mixture of 50mL of ethanol and 1mL of ammonia water was added dropwise. After stirring for 15min at 30°C, 10mL of tetraethoxysilane (TEOS) was added and reacted for 1h.

Embodiment 3

[0038] [Example 3] Magnetic particle coating hydrophobic layer (Fe 3 o 4 @SiO 2 @SiWO, WO means hydrophobic group)

[0039] Following Example 2, continue to add 1 mL of ammonia water, 10 mL of TEOS, and 6 mL of dimethyldiethoxysilane (DMDES) for reaction, and then add 1 mL of ammonia water and 6 mL of DMDES after 30 minutes for reaction for 4 hours. The magnet is settled, washed with water, and repeated many times until it is nearly neutral. Then wash twice with ethanol. After dispersing the magnetic powder with 150 mL of ethanol, add 1 mL of ammonia water and 6 mL of DMDES under stirring, and react for 2 days. The magnet is settled, washed with water several times, and then washed with ethanol until nearly neutral. Drain the remaining ethanol and dry to obtain hydrophobic magnetic particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com