Micro-fluidic chip based on MHD control

A technology of microfluidic chips and microchannels, applied in the field of machinery, can solve the problems of unfavorable integrated development, low sensitivity, and excessive volume, and achieve the effects of convenient integrated development, improved detection efficiency, and low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

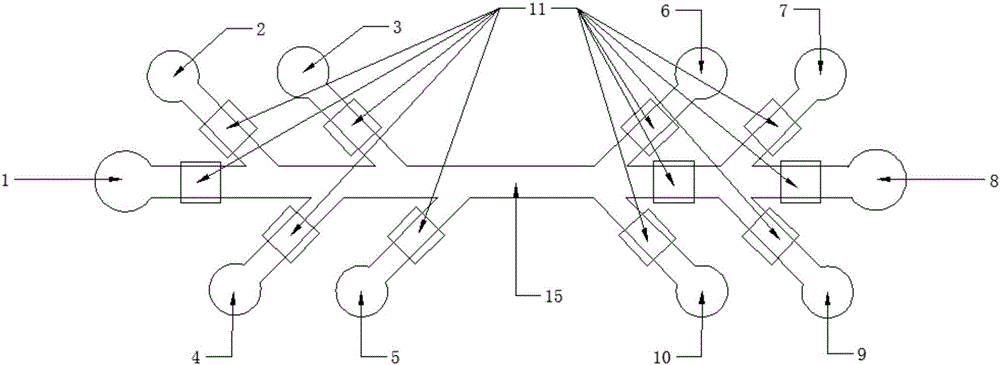

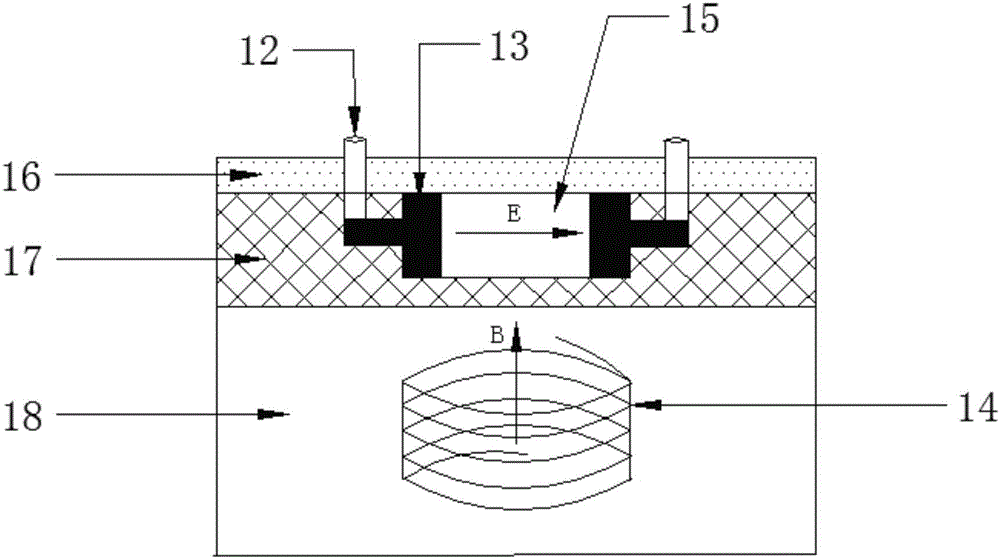

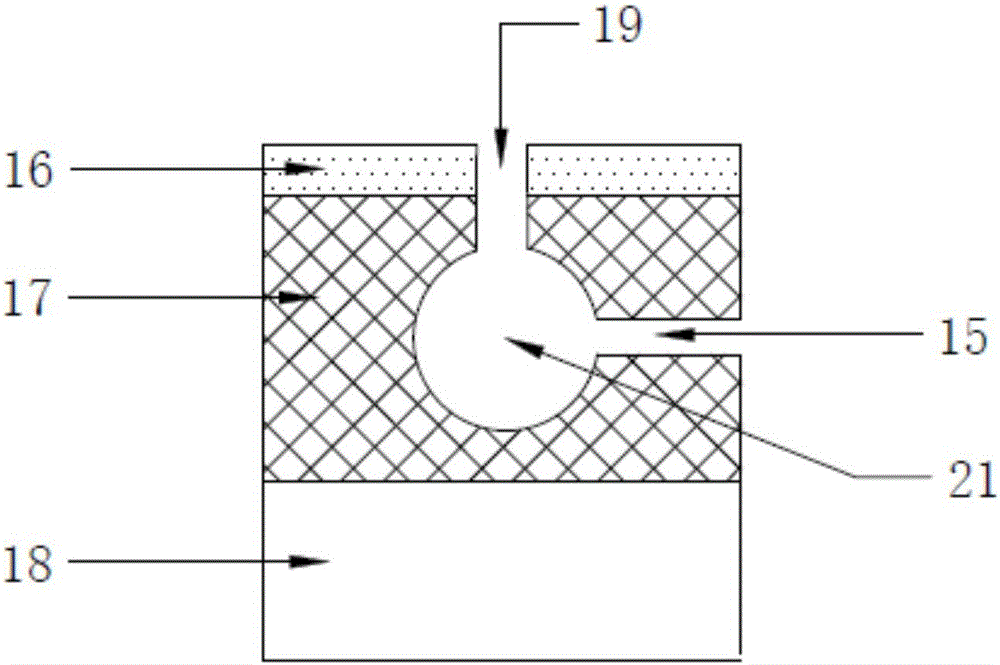

[0026] Such as figure 1 As shown, the present invention provides a microfluidic chip based on MHD control. The microfluidic chip adopts a three-layer structure, and the first layer is a quartz glass sheet 18, such as figure 2 Shown; The second layer is the microchannel layer 17, which is coated with a layer of SU-8 photoresist on the cleaned quartz glass sheet, and after drying, the microchannel 15 is photoetched with an exposure machine. The electrode 13 is electroplated on the channel 15, and the electrode 13 is connected to the electrode connecting column 12. The quartz glass sheet 18 directly below the micro-channel 15 has a groove that can be embedded with a micro-coil 14. The micro-channel layer 17 also includes a liquid storage chamber. 21 and a detection chamber 22; the third layer is the PDMS cover sheet layer 16, on which the outlet of the electrode connection column 12, the injection port 19 and the observation port 20 are left. Specifically include:

[0027] The...

Embodiment 2

[0034] The sample of the liquid storage chamber 2 of the present invention flows to the detection chamber D9: the sample is injected into the liquid storage chamber 2 through the injection port 19, and the adjustment is applied to the liquid storage chamber 2, the liquid storage chamber 3, the liquid storage chamber 4, and the liquid storage chamber 2. The direction of the electric field and the magnetic field of the AC MHD driven pump 11 on the tributaries where the liquid chamber 5, the detection chamber A6, the detection chamber B7, and the detection chamber E10 are located, the direction of the Lorentz force that the sample receives under the action of the electromagnetic field points to the main channel; and the sample The Lorentz force received by the AC MHD driven pump 11 flowing through the tributary where the detection chamber D9 is located points to the detection chamber D9; adjust the direction of the electric field and magnetic field of the AC MHD driven pump 11 clos...

Embodiment 3

[0036] The sample of the liquid storage chamber-1 of the present invention is mixed with the reagent of the liquid storage chamber three 3 and the reagent of the liquid storage chamber four 4 and flows to the detection chamber A6 and the detection chamber E10: the sample is injected into the liquid storage chamber-1 through the injection port 19, and the sample is injected into the liquid storage chamber-1. Reagent is injected into liquid storage chamber three 3 , and reagent is injected into liquid storage chamber four 4 . Adjust the direction of the electric field and the magnetic field of the AC MHD driven pump 11 applied to the tributaries where the liquid storage chamber 2, liquid storage chamber 3, liquid storage chamber 4, and liquid storage chamber 5 are located, so that the Loren The direction of the force points to the main channel; adjust the direction of the electric field and the magnetic field of the AC MHD drive pump 11 close to the liquid storage chamber 1, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com