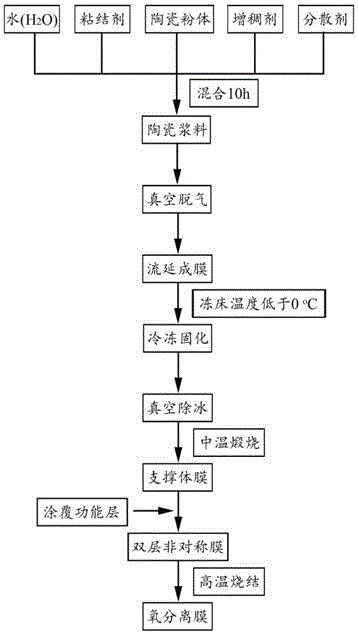

Method for shaping gradient-straight-hole double-layer asymmetric ceramic oxygen separation membrane

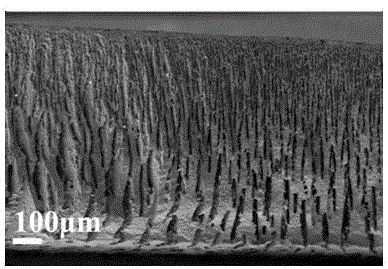

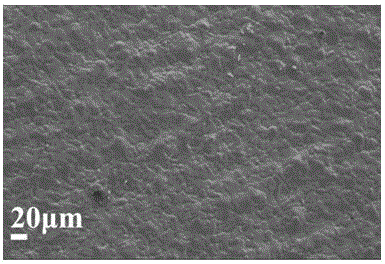

A forming method and technology of oxygen separation membrane, which is applied in the forming field of gradient straight hole asymmetric ceramic oxygen separation membrane, can solve the problem of high tortuosity factor of asymmetric ceramic oxygen separation membrane support body, lower gas transmission speed on support body, and restrict oxygen Improve the surface oxygen exchange rate, improve the oxygen permeation flux, and reduce the tortuosity factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] (1) Ammonium polyacrylate, polypropylene and polysaccharide were dissolved in deionized water to form an aqueous solution; gadolinium oxide-doped cerium oxide (Ce 0.9 Gd 0.1 o 1.95 , GDC) powder and strontium oxide doped lanthanum manganate ((La 0.8 Sr 0.2 ) 0.95 MnO 3-δ , LSM) powder according to the mass ratio of 62.2:37.8 ball mill and mix uniformly to make GDC-LSM composite ceramic powder; add GDC-LSM composite ceramic powder to the aqueous solution prepared above, ball mill and mix uniformly to obtain a stable water-based ceramic slurry , the mass content of deionized water, ceramic powder and organic matter in the water-based ceramic slurry is 32.2%, 57.8% and 10.0%, respectively, and the organic matter is 4.5% ammonium polyacrylate, 4% polypropylene and 1.5% polysaccharide;

[0030] (2) Put the water-based ceramic slurry in a vacuum pump, and vacuum degass for 10 minutes to remove the air bubbles introduced during the mixing process of ball milling;

[0031...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com