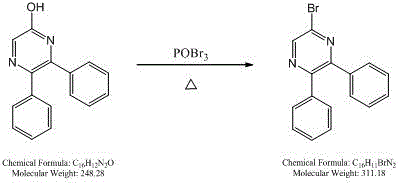

Preparation method of 2-bromine-5,6-diphenyl pyrazine

A technology of diphenylpyrazine and hydroxyl group, applied in the field of preparation of 2-bromo-5,6-diphenylpyrazine, can solve the problems of low yield and product purity, complicated process and high cost, and achieve product quality Stable, high-purity, and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 5-hydroxy-2,3-diphenylpyrazine (1.0g, 4.0mmol) in 10mL tetrahydrofuran, according to the molar ratio of 5-hydroxy-2,3-diphenylpyrazine and phosphorus oxybromide 1:1.2 Proportionally add phosphorus oxybromide (1.35g, 4.8mmol), and react at 65°C for 3 hours. After the reaction is detected by TLC, slowly pour the reaction solution into 20g of ice-water mixture while it is hot, and continue stirring for 20 minutes. Adjust the pH value to 8.0 with saturated potassium carbonate solution, extract 20mL*3 times with ethyl acetate, wash with 10mL saturated brine, dry over anhydrous sodium sulfate, and remove the solvent by rotary evaporation to obtain the crude product of 2-bromo-5,6-diphenylpyrazine , the crude product was recrystallized with methanol to obtain 1.02 g of pure product 2-bromo-5,6-diphenylpyrazine, the product yield was 82%, and the product purity was 98%.

Embodiment 2

[0020] Dissolve 5-hydroxy-2,3-diphenylpyrazine (1.0g, 4.0mmol) in 10mL of benzene, according to the molar ratio of 5-hydroxy-2,3-diphenylpyrazine and phosphorus oxybromide 1:2 Proportionally add phosphorus oxybromide (2.25g, 8.0mmol), react at 80°C for 2.5 hours, TLC detects that the reaction is complete, slowly pour the reaction solution into 20g of ice-water mixture while it is hot, continue to stir for 20 minutes, and use saturated Adjust the pH value to 8.0 with potassium bicarbonate solution, extract 20mL*3 times with ethyl acetate, wash with 10mL of saturated brine, dry over anhydrous sodium sulfate, and remove the solvent by rotary evaporation to obtain the crude product of 2-bromo-5,6-diphenylpyrazine , the crude product was recrystallized with methanol to obtain 1.05 g of pure product 2-bromo-5,6-diphenylpyrazine, the product yield was 84%, and the product purity was 98%.

Embodiment 3

[0022] Dissolve 5-hydroxy-2,3-diphenylpyrazine (1.0g, 4.0mmol) in 10mL toluene, according to the molar ratio of 5-hydroxy-2,3-diphenylpyrazine and phosphorus oxybromide 1:5 Add phosphorus oxybromide (6.22g, 20.0mmol) in proportion, react at 85°C for 2.0 hours, TLC detects that the reaction is complete, slowly pour the reaction solution into 30g of ice-water mixture while it is hot, continue to stir for 20 minutes, and use saturated Adjust the pH value to 8.0 with sodium bicarbonate solution, extract 30 mL*3 times with ethyl acetate, wash with 20 mL of saturated brine, dry over anhydrous sodium sulfate, and remove the solvent by rotary evaporation to obtain the crude product of 2-bromo-5,6-diphenylpyrazine , the crude product was recrystallized with methanol to obtain 1.10 g of pure product 2-bromo-5,6-diphenylpyrazine, the product yield was 88%, and the product purity was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com