Compound type net taste photoinitiator and UV curing coating

A photoinitiator, composite technology, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the effect of photoinitiator's deodorization effect, which has not been reported yet, less use, and photoinitiation efficiency. Low problems, to achieve the effect of optimizing curing rate and material properties, deodorizing properties, and high initiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

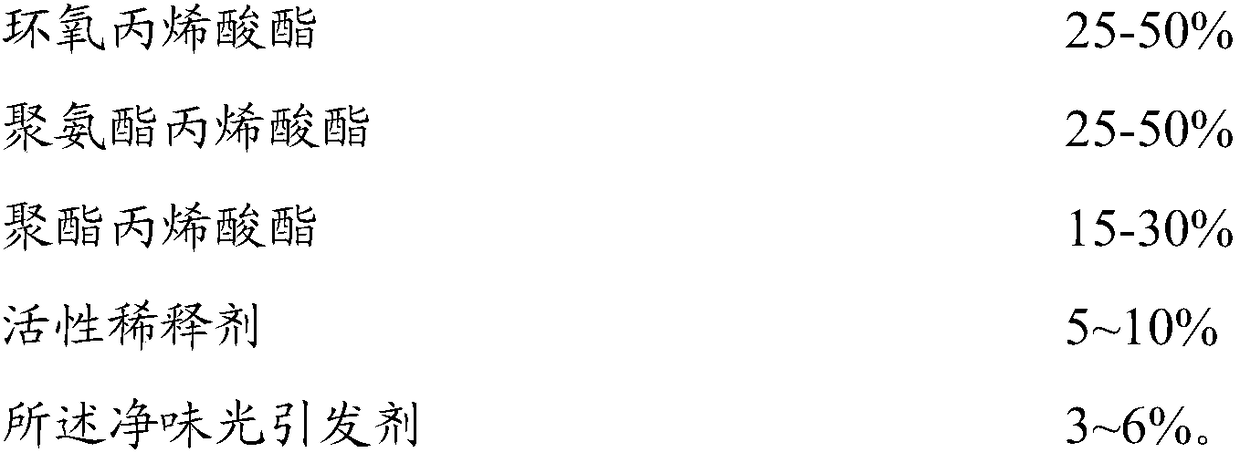

[0044] The present embodiment adopts a kind of compound type net taste photoinitiator, comprises the component of following percentage by weight:

[0045] Nano Zinc Oxide 30%

[0046] Macromolecular photoinitiator 70%.

[0047] The preparation method of the above-mentioned nano-zinc oxide: dry the zinc oxide in a vacuum oven at a temperature of 60° C. and a relative vacuum pressure of about -0.095 MPa for 3 hours, and then use ultrasonic treatment for 10 minutes to obtain a nano-zinc oxide with an average diameter of 127 nanometers. , the purity is greater than 99%;

[0048] Synthesis of macromolecular photoinitiator: Weigh 2-hydroxy-2-methyl-1-phenyl-1-propanone, isophorone diisocyanate and hydroxyethyl acrylate, and the molar ratio is 1.05:1:1; React isophorone diisocyanate with hydroxyethyl acrylate at 50°C for 2 hours, then add 2-hydroxy-2-methyl-1-phenyl-1-propanone and 1-hydroxycyclohexyl phenyl ketone , reacted at 60°C for 4 hours;

[0049] Preparation of odor-free ...

Embodiment 2

[0055] The present embodiment adopts a kind of compound type net taste photoinitiator, comprises the component of following percentage by weight:

[0056] Nano Zinc Oxide 40%

[0057] Macromolecular photoinitiator 60%.

[0058] The preparation method of the above-mentioned nano-zinc oxide: dry the zinc oxide in a vacuum drying oven at a temperature of 60° C. and a relative vacuum pressure of about -0.095 MPa for 3 hours, and then use ultrasonic treatment for 20 minutes to obtain a nano-zinc oxide with an average diameter of 108 nanometers. , the purity is greater than 99%;

[0059] Synthesis of macromolecular photoinitiator: Weigh 1-hydroxycyclohexyl phenyl ketone, isophorone diisocyanate and hydroxyethyl methacrylate, and its molar ratio is 1.1:1:1; The isocyanate and hydroxyethyl methacrylate were first reacted at 30°C for 4 hours, then added 1-hydroxycyclohexyl phenyl ketone, and reacted at 70°C for 3 hours;

[0060] Preparation of odor-free photoinitiator: add the above...

Embodiment 3

[0066] The present embodiment adopts a kind of compound type net taste photoinitiator, comprises the component of following percentage by weight:

[0067] Nano Zinc Oxide 30%

[0068] Macromolecular photoinitiator 70%.

[0069] The preparation method of the above-mentioned nano-zinc oxide: dry the zinc oxide in a vacuum oven at a temperature of 60°C and a relative vacuum pressure of about -0.095MPa for 3 hours, and then use ultrasonic treatment for 30 minutes to obtain a nano-zinc oxide with an average diameter of 82 nanometers. , the purity is greater than 99%;

[0070] Synthesis of macromolecular photoinitiator: Weigh 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, isophorone diisocyanate and hydroxypropyl acrylate, and its molar ratio is 1.05 :1:1; react isophorone diisocyanate and hydroxypropyl acrylate at 50°C for 2 hours, then add 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone , reacted at 80°C for 3 hours;

[0071] Preparation of odor-free photoinitiator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com