A kind of preparation method and application of modified titanium dioxide as photoinitiator

A titanium dioxide and modification technology, which is applied in the field of preparation of modified titanium dioxide, can solve the problems of poor loading modification efficiency, insufficient efficiency of titanium dioxide photoinitiator, and efficiency that cannot meet the requirements of the application, and achieve the goal of improving the initiation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Fluorinated titanium powder (FTIO 2 Preparation

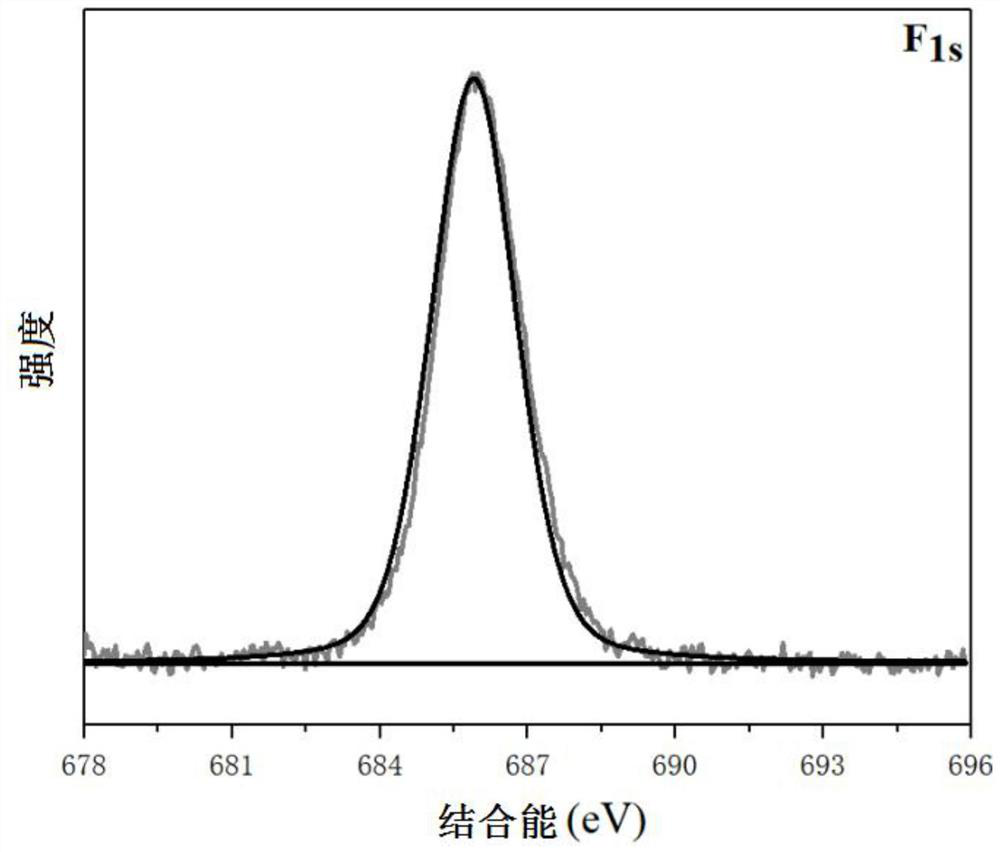

[0045] Accurate weighing 10.00g TiO 2 (Naked the surface of the particles, there is no surface-containing anatase-containing modified substance, Di-titanium titanium dioxide, D 50 The original particle size is 0.3-1.2 μm), 10.00GNH 4 F, dissolved in 150 ml of deionized water, ultrasound (200W) oscillation of dispersed TiO 2 Particles until the titanium white powder scraper particle diameter is less than 2.5 μm. The medium temperature magnetic force was then stirred (960 rpm) for 6 h, and the white lasu liquor cence (10500 rpm) was taken for 5 min, poured down, washed with deionized water, after washing (200W) oscillated for 10 min, then centrifugation (10500 rpm) for 5 min, fell To the supernatant, washed with deionized water, the above-mentioned ultrasound-centrifugal operation was repeated 3 times to remove unscapable NH 4 F; Finally, the above product was dried in a 65 ° C oven for 6 h to give a fluorinated TiO ...

Embodiment 2

[0048] Example 2 Male uric acid @ftio 2 Preparation

[0049] Exactly weighs 10.00 g of fluorinated TiO 2 , 15.00g of mission, dissolved in 150 ml of deionized water, ultrasound (200W) oscillation dispersion reunion TiO 2 Particles until the titanium white powder scraper particle diameter is less than 2.5 μm. Then 60 ° C magnetic stir (960 rpm) for 6 h, and the white lasu liquor centrifugation (10500 rpm) was taken for 5 min, and the supernatant was poured, washed with deionized water. After washing, the ultrasound (200W) was oscillated for 10 min, and then centrifuged (10500 rpm) was separated for 5 min. Pour the supernatant, washed with deionized water, the above ultrasound-centrifugal operation was repeated 3 times to remove unscaded glycine; 2 .

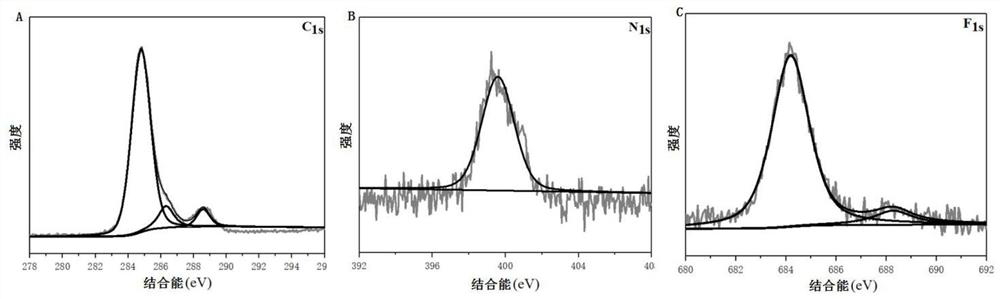

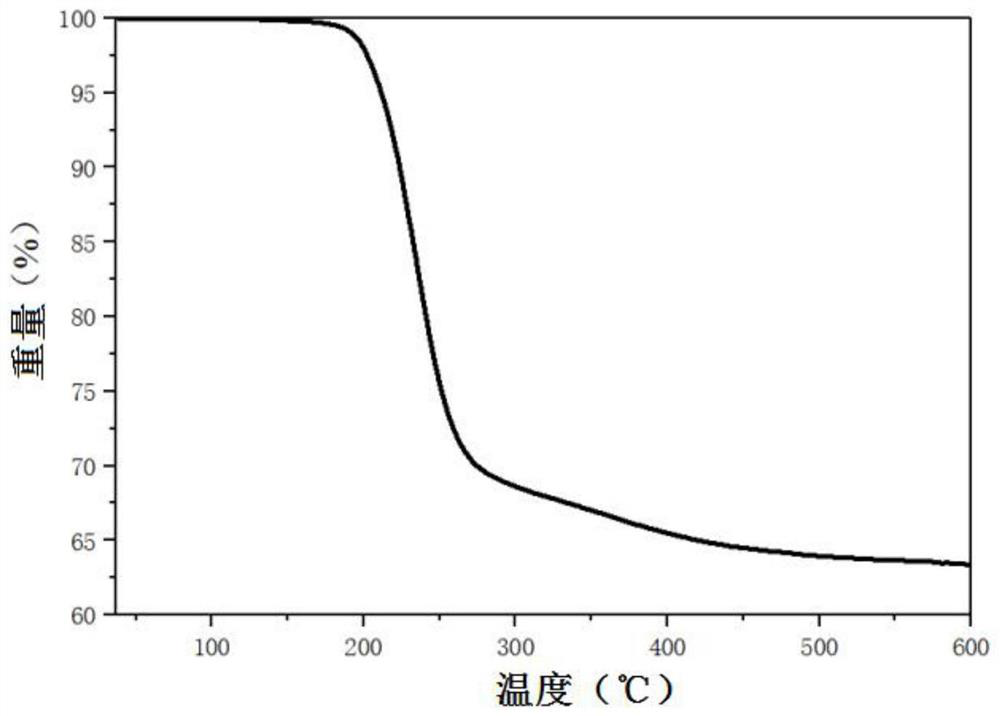

[0050] Get the acquired murret @ftio 2 Perform XPS detection, the particle surface element binding energy signal analysis shows that 1s Performing a peak fitting, a C-C signal appears at 284.8EV, a C-O signal appears at 286.3EV, and a...

Embodiment 3

[0051] Example 3 Citric acid @ftio 2 Preparation

[0052] Accurate weighing 10.00 g of the fluorinated TiO 2 , 15.00g of citric acid, dissolved in 150 mL deionized water, ultrasound (200W) oscillating dispersion reunion TiO 2 Particles until the titanium white powder scraper particle diameter is less than 2.5 μm. Then 60 ° C magnetic stir (960 rpm) for 6 h, and the white lasu liquor centrifugation (10500 rpm) was taken for 5 min, and the supernatant was poured, washed with deionized water. After washing, the ultrasound (200W) was oscillated for 10 min, and then centrifuged (10500 rpm) was separated for 5 min. The supernatant was pressed, washed with deionized water, and the above ultrasound-centrifugal operation was repeated 3 times to remove unscaptive carboxylic acids. Finally, the above product was vacuum 6 h in a 65 ° C oven to give citric acid @ftio 2 .

[0053] Getting citric acid @ftio 2 Perform XPS detection, the particle surface element binding energy signal analysis show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com