Preparation method and application of modified titanium dioxide serving as photoinitiator

A titanium dioxide, modification technology, applied in applications, home appliances, coatings, etc., can solve the problems of poor load modification efficiency, reduced fire safety and environmental protection, and insufficient efficiency of titanium dioxide photoinitiators to achieve initiation efficiency Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

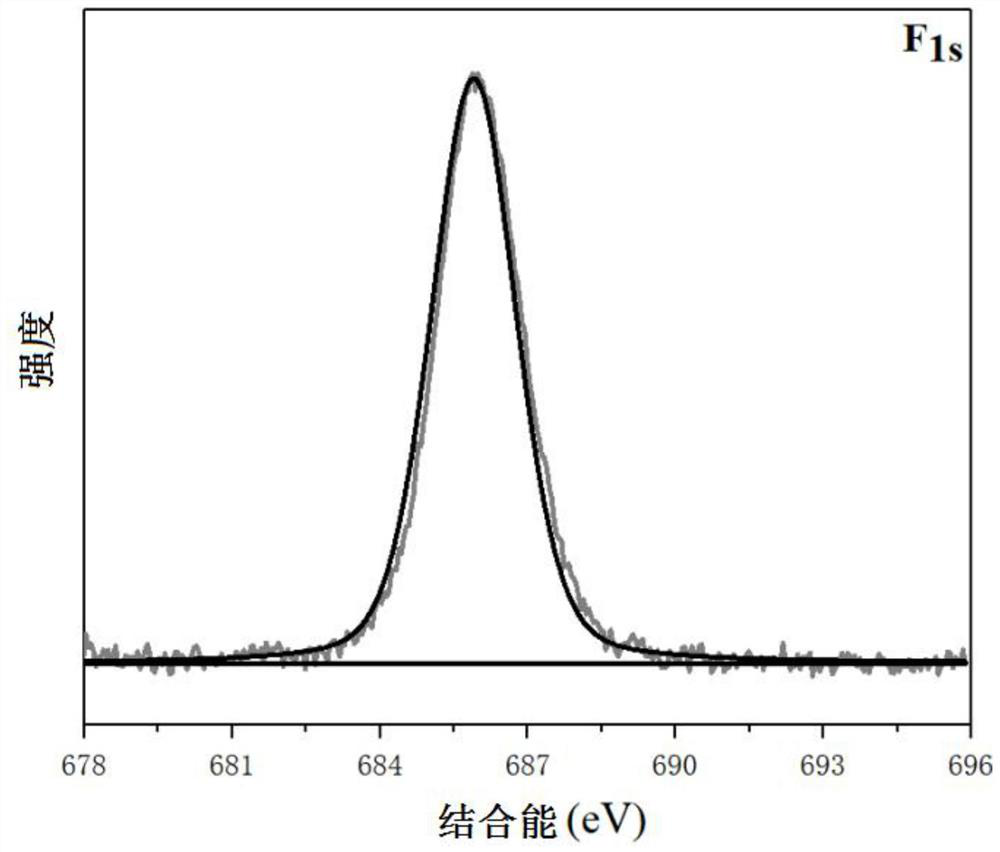

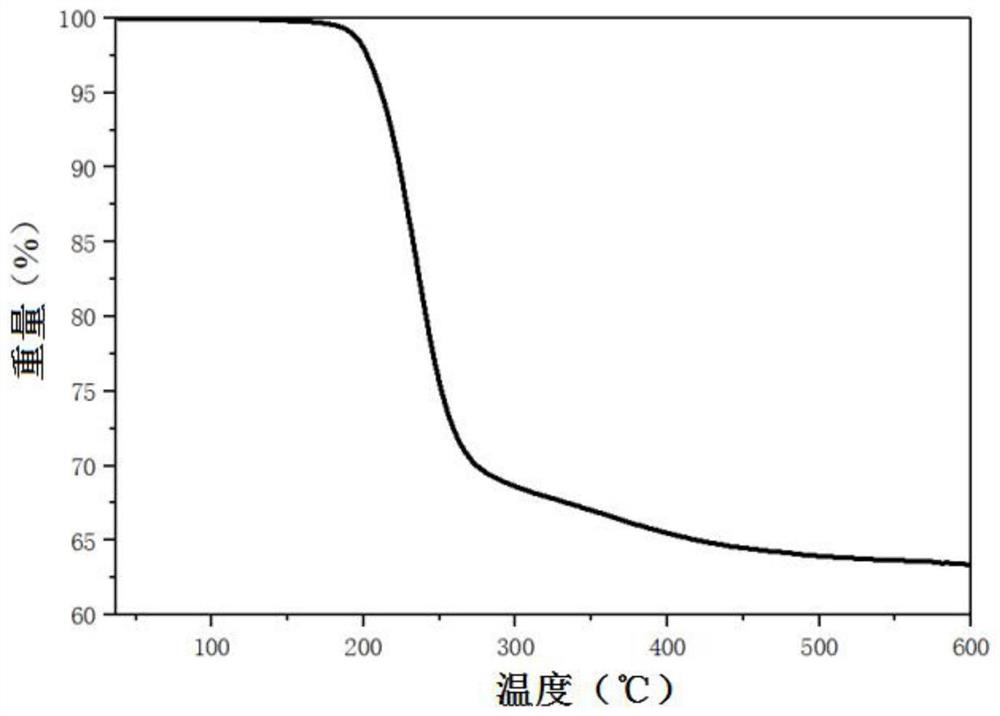

[0044] Embodiment 1 titanium dioxide fluoride (FTiO 2 ) preparation

[0045] Accurately weigh 10.00g TiO 2 (anatase-type titanium dioxide with bare particle surface and without any surface-coated modification substances, D 50 The primary particle size is 0.3-1.2μm), 10.00gNH 4 F, dissolved in 150mL deionized water, ultrasonic (200W) vibration to disperse the agglomerated TiO 2 Particles until the particle size of the titanium dioxide scraper is less than 2.5 μm. Then magnetically stir (960rpm) at room temperature for 6h, absorb the white milk slurry and centrifuge (10500rpm) for 5min, pour off the supernatant, wash with deionized water, and ultrasonically (200W) shake for 10min after washing, then centrifuge (10500rpm) for 5min, pour Remove the supernatant, wash with deionized water, and repeat the above ultrasonic-centrifugation operation 3 times to remove unadsorbed NH 4 F; Finally, the above product was vacuum-dried in an oven at 65°C for 6 hours to obtain fluorinated ...

Embodiment 2

[0048] Example 2 hippuric acid @FTiO 2 preparation of

[0049] Accurately weigh the fluorinated TiO of 10.00g embodiment 2 , 15.00g hippuric acid, dissolved in 150mL deionized water, ultrasonic (200W) vibration disperse the agglomerated TiO 2 Particles until the particle size of the titanium dioxide scraper is less than 2.5 μm. Then magnetically stir (960rpm) at 60°C for 6h, absorb the white milk slurry and centrifuge (10500rpm) for 5min, pour off the supernatant, wash with deionized water, and ultrasonically (200W) shake for 10min after washing, then centrifuge (10500rpm) for 5min. Pour off the supernatant, wash with deionized water, and repeat the above ultrasonic-centrifugation operation 3 times to remove unadsorbed glycine; finally, vacuum-dry the above product in an oven at 65°C for 6 hours to obtain hippuric acid@FTiO 2 .

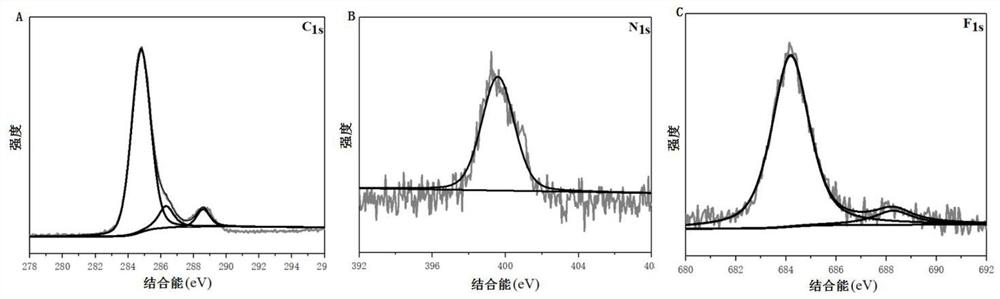

[0050] To get hippurate @FTiO 2 Carried out XPS detection, particle surface element binding energy signal analysis showed that for C 1s Perform...

Embodiment 3

[0051] Example 3 Citric acid@FTiO 2 preparation of

[0052] Accurately weigh the fluorinated TiO of 10.00g embodiment 1 2 , 15.00g citric acid, dissolved in 150mL deionized water, ultrasonic (200W) vibration to disperse the agglomerated TiO 2 Particles until the particle size of the titanium dioxide scraper is less than 2.5 μm. Then magnetically stir (960rpm) at 60°C for 6h, absorb the white milk slurry and centrifuge (10500rpm) for 5min, pour off the supernatant, wash with deionized water, and ultrasonically (200W) shake for 10min after washing, then centrifuge (10500rpm) for 5min. Pour off the supernatant, wash with deionized water, and repeat the above-mentioned ultrasonic-centrifugation operation 3 times to remove unadsorbed carboxylic acid. Finally, the above product was vacuum-dried in an oven at 65°C for 6h to obtain citric acid@FTiO 2 .

[0053] to the resulting citric acid @FTiO 2 Carried out XPS detection, particle surface element binding energy signal analysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com