Preparation method of natural macromolecular hollow microspheres

A technology of natural macromolecules and hollow microspheres is applied in the field of preparation of natural macromolecular hollow microspheres. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

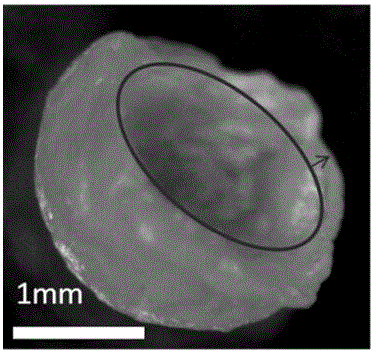

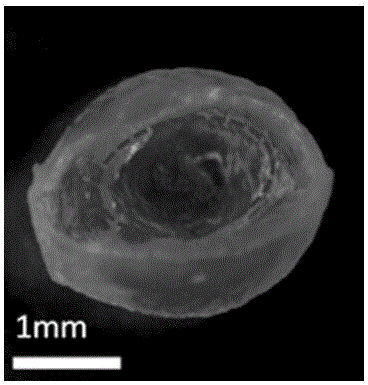

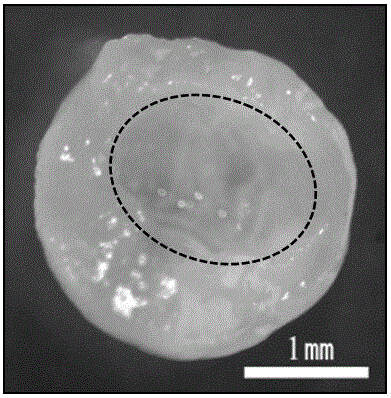

[0027] Disperse chitin powder in a mixture of 20 wt% KOH, 50 wt% NaOH, and 12 wt% urea, freeze it at -30°C, place it for 12 hours, and then thaw it into a solution at room temperature with a concentration of 0.001 wt %. Put the chitin solution into the syringe, the distance between the needle tip and the receiving device is 3 cm, the voltage between the needle tip and the receiving device is 0Kv, and the driving speed of the pump is 0.1mlh -1 , the coagulation liquid is liquid nitrogen, and the chitin balls are dried in a freeze dryer at -20°C. The freeze-dried microspheres are put into water and rinsed until neutral, and freeze-dried again to obtain neutral chitin hollow microspheres.

Embodiment 2

[0029] Disperse chitin powder in a mixture of 20 wt% KOH, 50 wt% NaOH, and 12 wt% thiourea, freeze it at -30°C, place it for 12 hours, and then thaw it into a solution at room temperature with a concentration of 8 wt%. Put the chitin solution into the syringe, the distance between the needle tip and the receiving device is 3 cm, the voltage between the needle tip and the receiving device is 0Kv, and the driving speed of the pump is 0.1 ml h -1 , the coagulation liquid is liquid nitrogen, and the chitin balls are dried in a freeze dryer at -20°C. The freeze-dried microspheres are put into water and rinsed until neutral, and freeze-dried again to obtain neutral chitin hollow microspheres.

Embodiment 3

[0031] Disperse chitin powder in a mixture of 20 wt% KOH, 20 wt% LiOH, and 12 wt% urea, freeze it at -30°C, place it for 12 hours, and then thaw it into a solution at room temperature with a concentration of 0.001 wt %. Put the chitin solution into the syringe, the distance between the needle tip and the receiving device is 100 cm, the voltage between the needle tip and the receiving device is 0Kv, and the driving speed of the pump is 0.1ml h -1 , the coagulation liquid is liquid nitrogen, and the chitin balls are dried in a freeze dryer at -20°C. The freeze-dried microspheres are put into water and rinsed until neutral, and freeze-dried again to obtain neutral chitin hollow microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com