A method of photocatalytic synthesis of a jackfruit filament polysaccharide antibacterial membrane

A technology of jackfruit shreds and antibacterial film, applied in the field of photocatalytic synthesis of jackfruit shredded polysaccharide antibacterial film, to achieve the effects of extending shelf life, improving dispersibility, and eliminating white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

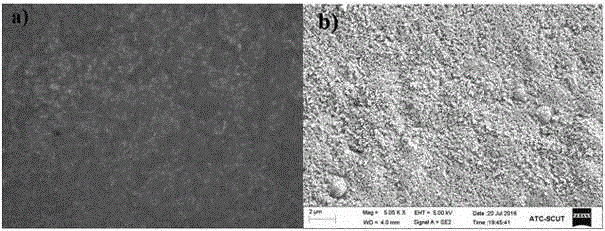

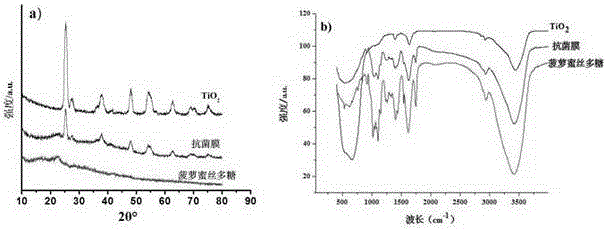

Image

Examples

Embodiment 1

[0035] The jackfruit silk degreasing powder and distilled water (80℃) were mixed and extracted at a ratio of 1:30 (v / v) for 3 hours, then concentrated by rotary evaporation to 1 / 3 to 1 / 4 of the original volume, and then 2.5 times of absolute ethanol was added. Leave it for 12 hours, centrifuge (8000r / min, 10min) to separate, freeze-dry the resulting precipitate to obtain jackfruit shredded polysaccharide; then dissolve the jackfruit shredded polysaccharide powder in deionized water to prepare approximately 50% polysaccharide solution, and mix with glycerin at a ratio of 1: The mass ratio of 0.016 was mixed and stirred for 1 hour, and then the water bath was heated to 80°C for 30 minutes, followed by vacuum degassing; the titanium dioxide (TiO 2 ) The particles are added to deionized water and ultrasonically dissolved; then 0.5% (w / w) TiO 2 The solution was slowly added to the heat-treated polysaccharide solution, stirred moderately for 30 minutes, and then placed in a photocataly...

Embodiment 2

[0040] The jackfruit silk degreasing powder and distilled water (80℃) were mixed and extracted at a ratio of 1:30 (v / v) for 3 hours, then concentrated by rotary evaporation to 1 / 3 to 1 / 4 of the original volume, and then 2.5 times of absolute ethanol was added. Leave it for 12 hours, centrifuge (8000r / min, 10min) to separate, freeze-dry the resulting precipitate to obtain jackfruit shredded polysaccharide; then dissolve the jackfruit shredded polysaccharide powder in deionized water to prepare approximately 50% polysaccharide solution, and mix with glycerin at 1: The mass ratio of 0.016 is mixed and stirred for 1 hour, and then the water bath is heated to 70°C for 45 minutes, followed by vacuum degassing; the titanium dioxide (TiO 2 ) The particles are added to deionized water and ultrasonically dissolved; then 1% (w / w) TiO 2 The solution was slowly added to the heat-treated polysaccharide solution, stirred moderately for 30 minutes, and then placed in a photocatalytic reactor (50...

Embodiment 3

[0045] The jackfruit silk degreasing powder and distilled water (80℃) were mixed and extracted at a ratio of 1:30 (v / v) for 3 hours, then concentrated by rotary evaporation to 1 / 3 to 1 / 4 of the original volume, and then 2.5 times of absolute ethanol was added. Leave it for 12 hours, centrifuge (8000r / min, 10min) to separate, freeze-dry the resulting precipitate to obtain jackfruit shredded polysaccharide; then dissolve the jackfruit shredded polysaccharide powder in deionized water to prepare approximately 50% polysaccharide solution, and mix with glycerin at 1: The mass ratio of 0.016 was mixed and stirred for 1 hour, and then the water bath was heated to 90°C for 20 minutes, followed by vacuum degassing; the titanium dioxide (TiO 2 ) The particles are added to deionized water and ultrasonically dissolved; then 2% (w / w) TiO 2 The solution was slowly added to the heat-treated polysaccharide solution, stirred moderately for 30 minutes, and then placed in a photocatalytic reactor (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com