Polycarbonate composite and product thereof

A composite material and polycarbonate technology, applied in the field of materials, can solve the problems of high toughness of composite materials, and achieve the effect of good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

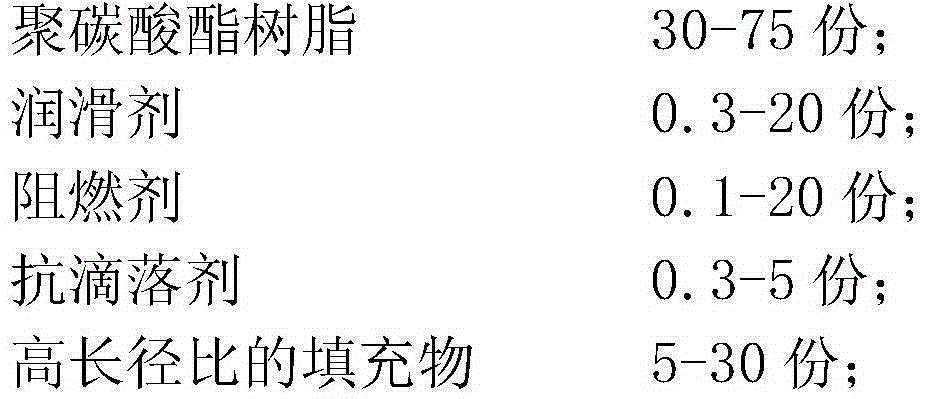

Method used

Image

Examples

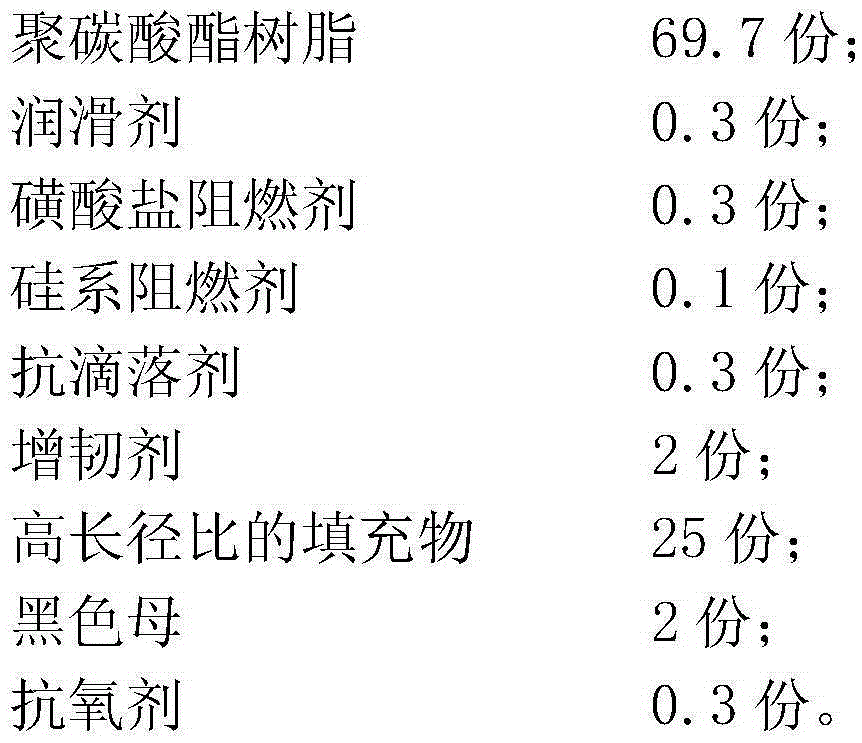

Embodiment 1

[0033]

[0034] The polycarbonate resin in Example 1 was stirred for 10 minutes using a single-shaft mixing bucket, and the remaining components were stirred for 10 minutes using a single-shaft mixing bucket; finally, the above mixture was added to a twin-screw extruder for melt extrusion and granulation , to produce polycarbonate composites.

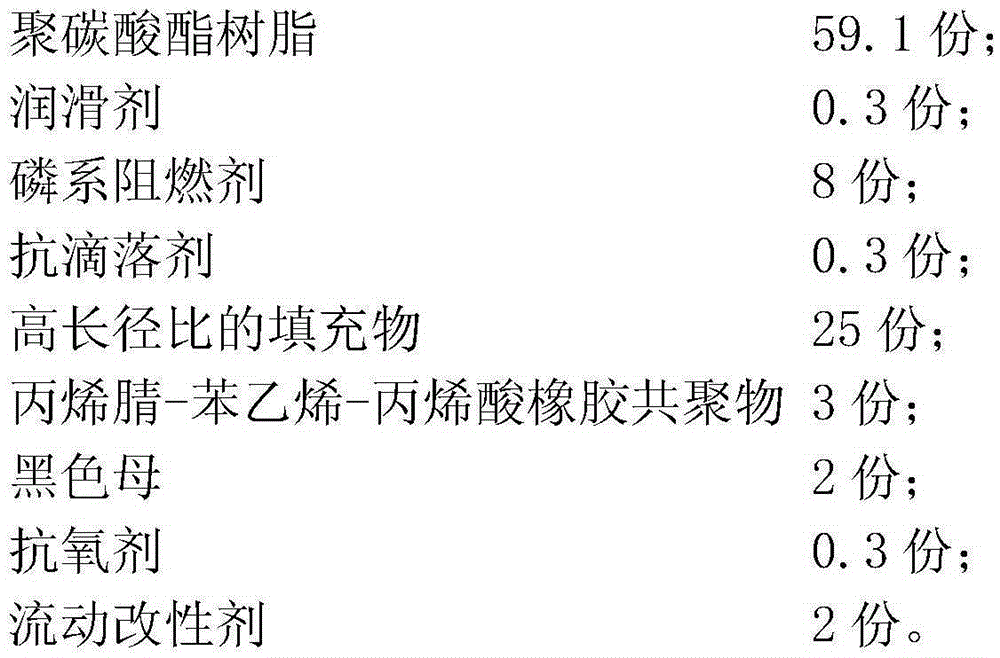

Embodiment 2

[0037]

[0038] The polycarbonate resin in Example 1 was stirred for 10 minutes using a single-shaft mixing bucket, and the remaining components were stirred for 10 minutes using a single-shaft mixing bucket; finally, the above mixture was added to a twin-screw extruder for melt extrusion and granulation , to produce polycarbonate composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com