Wear-resistant super-hydrophobic coating compound

A technology of super-hydrophobic coatings and compositions, applied in the direction of coatings, etc., can solve the problems of no literature reports, super-hydrophobic inconvenience, etc., and achieve the effects of mild conditions, convenient construction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

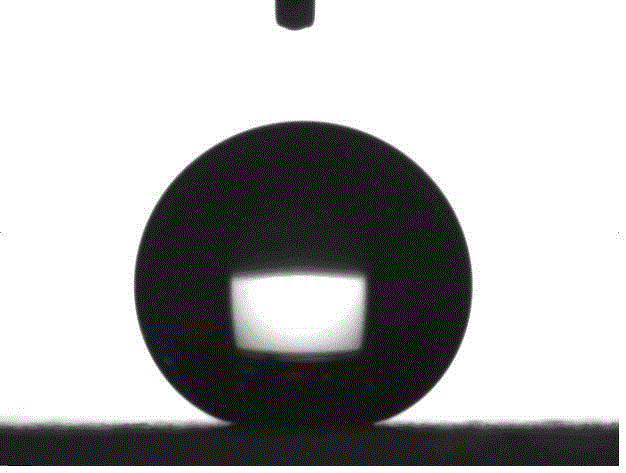

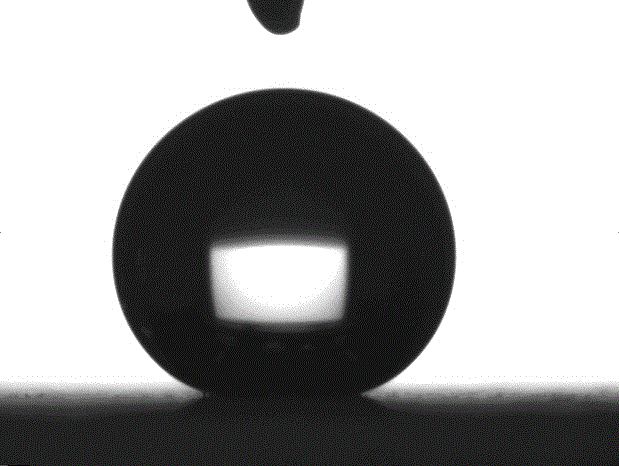

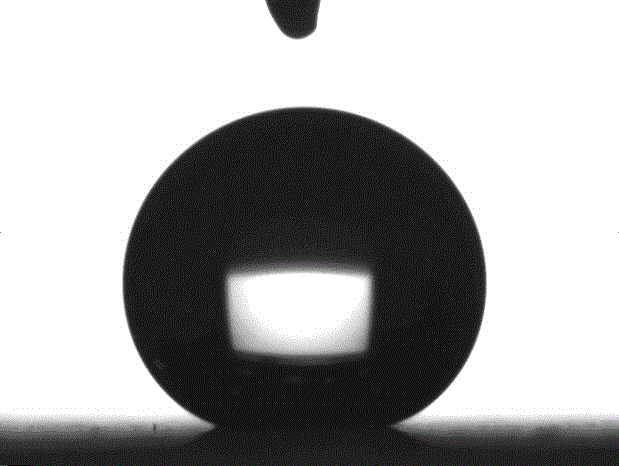

Image

Examples

Embodiment 1

[0046] First, prepare a three-component coating composition with the following formula: (i) 50 g of superhydrophobic nanosol with amino groups, the specific preparation method is as follows: 10 g of tetraethoxysilane is dissolved in 120 ml of isopropanol alcohol , add 10 g of water and 3 g of ammonia water, heat the reaction at 55 ° C for 4 hours to obtain a monodisperse silica solution; adjust the pH to 3.5, and then add 2.5 g of NH 2 (CH 2) 2 NH(CH 2 ) 3 Si(OCH 2 CH 3 ) 3 , after stirring for 4 hours at 50 ℃, add 5 g of tridecafluorooctyltriethoxysilane, and continue stirring for 5 hours to obtain a superhydrophobic sol, (ii) 10 g of wear-resistant silicone resin, (iii) 0.4 g of curing agentγ - Aminopropyltriethoxysilane. Then, 10 g of wear-resistant silicone resin was added to 50 g of superhydrophobic nano-sol with amino groups, stirred for 30 minutes, and then 0.4 g of curing agent γ-aminopropyltriethoxysilane was added, and stirred for 10 minutes. Finally, spread ...

Embodiment 2

[0049] First, prepare a coating composition with the following formula: (i) Take 50 g of superhydrophobic nano-sol with amino groups, the specific preparation method is: dissolve 10 g of tetraethoxysilane in 100 ml of ethanol, add 10 g Water and 2 g ammonia water were reacted by heating at 60°C for 4 hours to obtain a monodisperse silica solution; adjust the pH to 3.5, and then add 3 g NH 2 (CH 2 ) 3 Si(OCH 2 CH 3 ) 3 , Stir at 50 ℃ for 4 hours, add 6 g of n-octadecyltriethoxysilane, and continue stirring for 5 hours to obtain a superhydrophobic sol, (ii) 10 g of silicone-modified silicone resin (solid content 20%). Then, 10 g of silicone-modified silicone resin was added to 70 g of superhydrophobic nano-sols with amino groups, and stirred for 30 minutes. Finally, apply it on a 7 cm*2.5 cm glass slide and cure at 80 ℃ for 0.5 hours.

[0050] After curing, the superhydrophobic coating has good transparency, abrasion resistance and hydrophobicity. Adopt ultraviolet spectr...

Embodiment 3

[0052] First, prepare a coating composition with the following formula: (i) 150 g of superhydrophobic nano-sol with amino group, the specific preparation method is as follows: dissolve 10 g of tetraethoxysilane in 120 ml of isopropanol alcohol, add 10 g water and 3 g ammonia water were heated and reacted at 55°C for 4 hours to obtain a monodisperse silica solution; adjust the pH to 3.5, and then add 2.5 g NH 2 (CH 2 ) 3 Si(OCH 3 ) 3 , Stir at 50 ℃ for 4 hours, add 5 g n-octyltrimethoxysilane, and continue stirring for 5 hours to obtain a superhydrophobic sol, (ii) 10 g fluororesin (solid content 50%). Then, 10 g of fluororesin was added to 70 g of superhydrophobic nano-sols with amino groups, and stirred for 30 minutes. Finally, spread on a 7 cm*2.5 cm glass slide and cure at 120 °C for 2 hours.

[0053] The cured superhydrophobic coating has good wear resistance. The contact angle of the superhydrophobic coating of this example measured by a contact angle measuring inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com