Road coating material capable of adsorbing tail gas as well as preparation method and application of road coating material

A coating material and road technology, applied in the direction of coating, separation methods, chemical instruments and methods, etc., can solve the problems of road surface skid resistance, water stability damage, affecting the performance of asphalt pavement, and slowing down the service life of asphalt pavement, etc. , to achieve the effect of abundant mineral resources, high mechanical and chemical stability, and great utilization potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

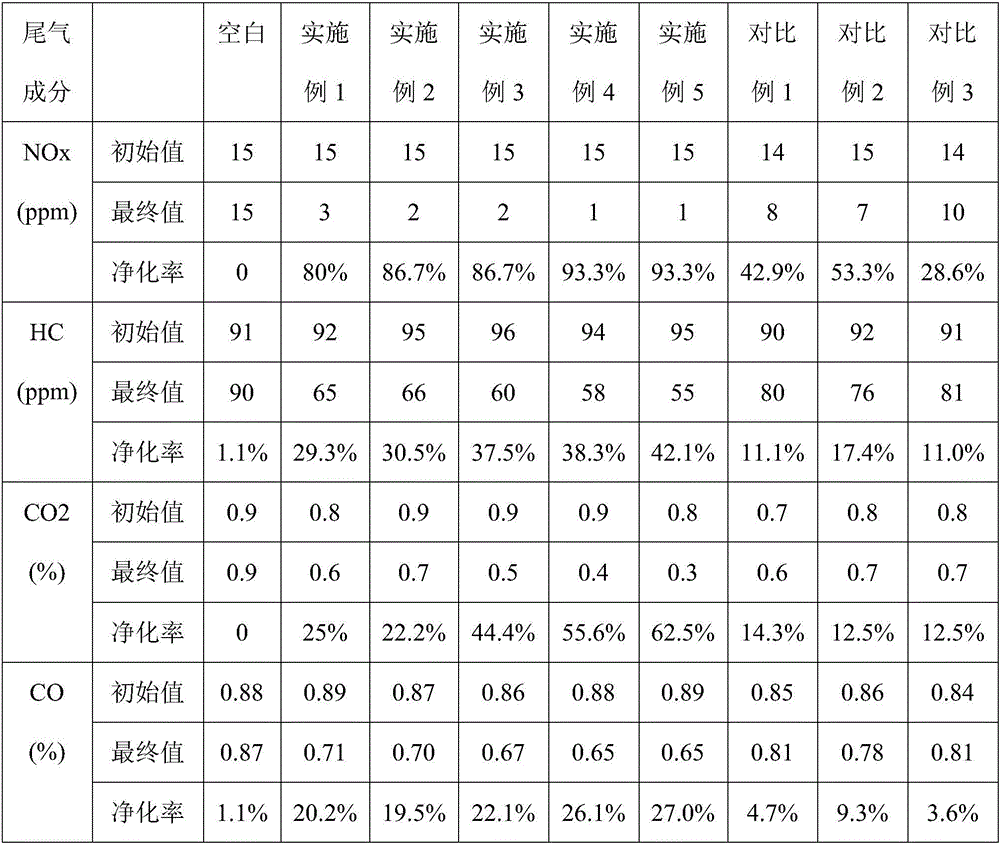

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a road coating material for absorbing tail gas is composed of the following raw materials in parts by weight: 42 parts of illite, 17 parts of vermiculite, 5 parts of cocamidopropyl betaine, 11 parts of triethanolamine, 3 parts citric acid.

[0019] Triethanolamine is mixed with deionized water whose mass is 5.5 times to prepare triethanolamine solution; cocamidopropyl betaine is mixed with deionized water whose mass is 3.2 times to prepare cocamidopropyl betaine solution. Mix and grind illite and citric acid, pass through a 150-mesh sieve, mix with triethanolamine solution, place in a polytetrafluoroethylene reactor, heat and stir at 126°C for 82 minutes, then lower it to 75°C to prepare mixture A . The vermiculite was pulverized and passed through a 150-mesh sieve, then mixed with cocamidopropyl betaine solution, and stirred at 92°C for 52 minutes to obtain mixture B. Mix mixture A and mixture B, stir at 75°C for 45 minutes...

Embodiment 2

[0021] In the embodiment of the present invention, a road coating material for absorbing tail gas is composed of the following raw materials in parts by weight: 50 parts of illite, 25 parts of vermiculite, 13 parts of cocamidopropyl betaine, 19 parts of triethanolamine, 7 parts of citric acid.

[0022] Triethanolamine is mixed with deionized water whose mass is 5.5 times to prepare triethanolamine solution; cocamidopropyl betaine is mixed with deionized water whose mass is 3.2 times to prepare cocamidopropyl betaine solution. Mix and grind illite and citric acid, pass through a 150-mesh sieve, mix with triethanolamine solution, put it into a polytetrafluoroethylene reactor, heat and stir at 126°C for 85 minutes, then lower it to 75°C to prepare mixture A . The vermiculite was pulverized and passed through a 150-mesh sieve, then mixed with cocamidopropyl betaine solution, and stirred at 92°C for 52 minutes to obtain mixture B. Mix mixture A and mixture B, stir at 75°C for 45 ...

Embodiment 3

[0024] In an embodiment of the present invention, a road coating material for absorbing tail gas is composed of the following raw materials in parts by weight: 44 parts of illite, 19 parts of vermiculite, 7 parts of cocamidopropyl betaine, 13 parts of triethanolamine, 4 parts citric acid.

[0025] Triethanolamine is mixed with deionized water whose mass is 5.5 times to prepare triethanolamine solution; cocamidopropyl betaine is mixed with deionized water whose mass is 3.2 times to prepare cocamidopropyl betaine solution. Mix and grind illite and citric acid, pass through a 150-mesh sieve, mix with triethanolamine solution, put it into a polytetrafluoroethylene reactor, heat and stir at 126°C for 83 minutes, then lower it to 75°C to prepare mixture A . The vermiculite was pulverized and passed through a 150-mesh sieve, then mixed with cocamidopropyl betaine solution, and stirred at 92°C for 52 minutes to obtain mixture B. Mix mixture A and mixture B, stir at 75°C for 45 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com