Water-based colored asphalt paint, its preparation method and usage

A technology for colored asphalt and asphalt coatings, applied in rosin coatings, fire-resistant coatings, coatings, etc., can solve the problems of high cost of resin glued materials, loss of color effect of black stones, and easy wear off of colored pigments, so as to reduce road surface water. The effect of infiltrating into the roadbed, helping to guide traffic, prolonging service life and maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

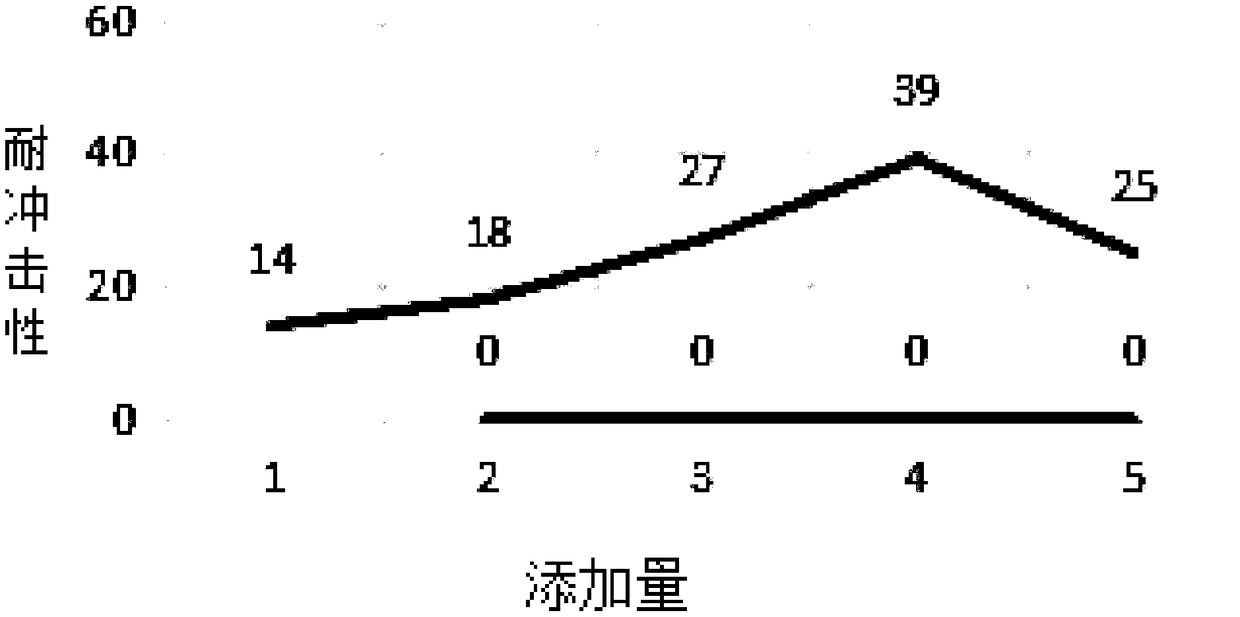

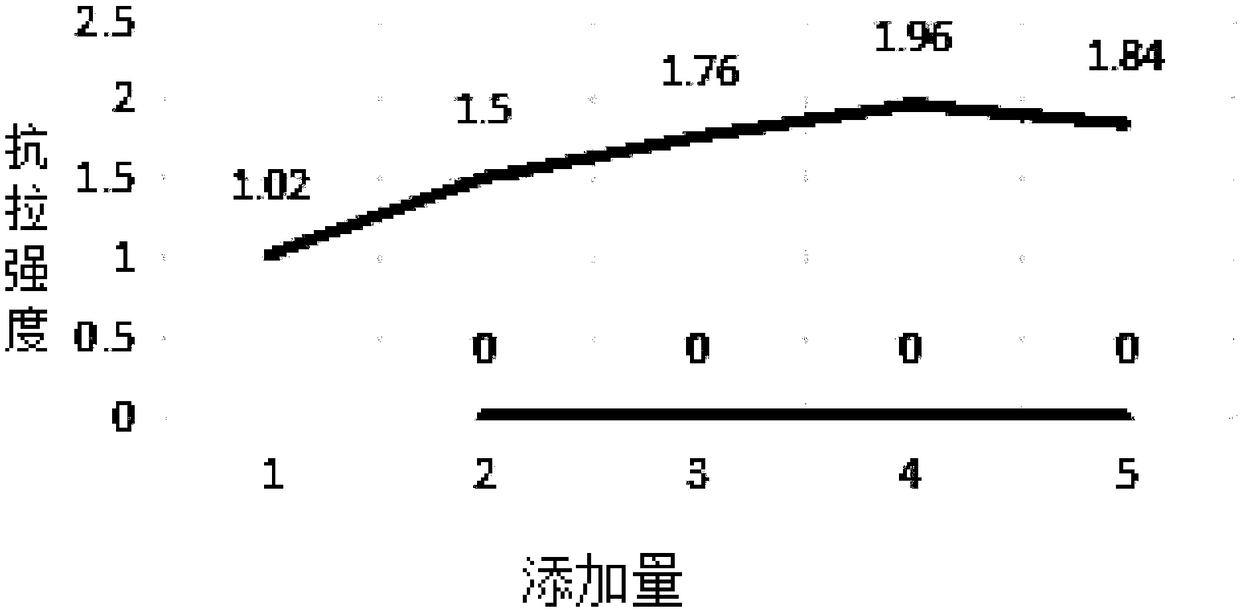

[0036] The preparation method of the water-based colored asphalt paint of the present invention is obtained by uniformly mixing the water-based modified asphalt with pigments (iron oxides), reinforcing fibers, fillers and sand; the water-based modified asphalt is mixed with pigments (iron oxides), The filler and the gravel are mixed in a weight ratio of 45-55:5-10:15-25:20-25; the amount of the reinforcing fiber is 4‰ of the total weight of the dry base material of the asphalt paint.

[0037] The preparation method of the water-based colored asphalt paint also includes the preparation of water-based modified asphalt, mixing 60-65 parts by weight of modified resin, 30-35 parts by weight of water, and 2-2.5 parts by weight of surfactant Made by high-speed shear colloid mill.

[0038] The preparation method of the described water-based colored asphalt paint also includes the preparation of modified resin, 40-50 parts by weight of modified c9 petroleum resin, 10-15 parts by weight...

Embodiment 1

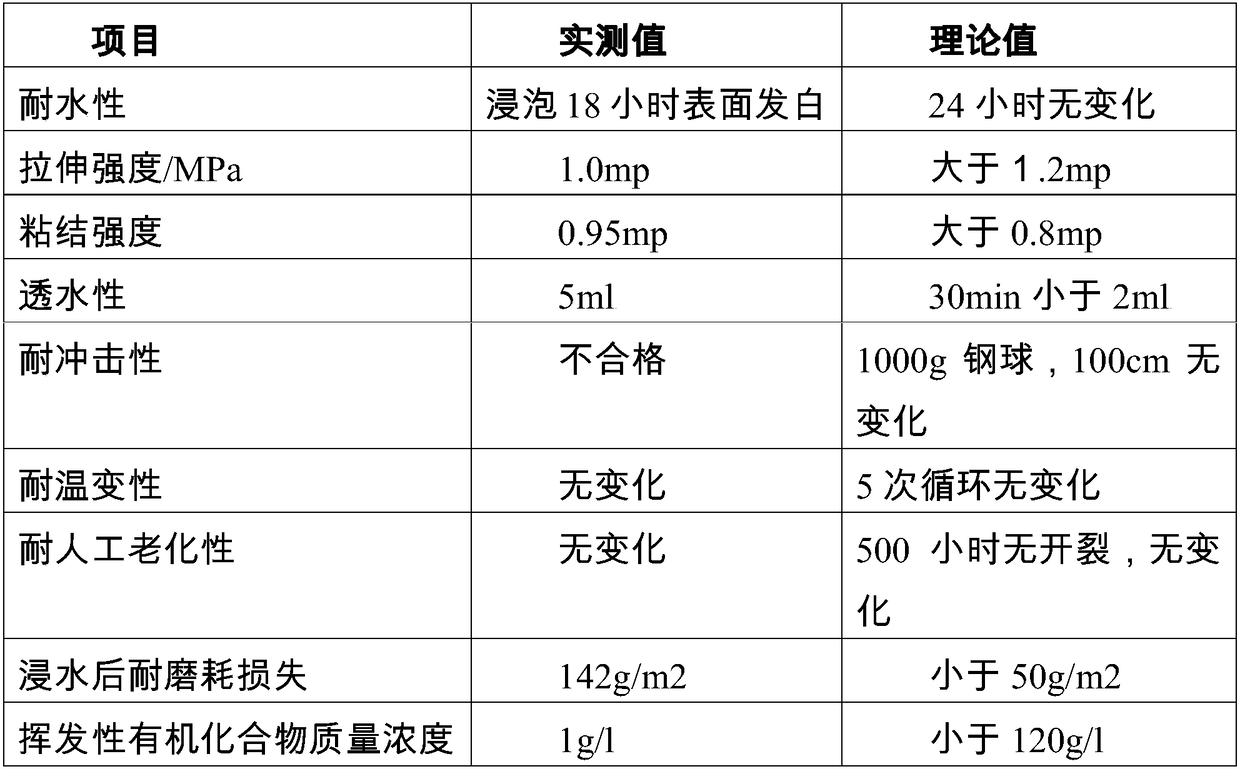

[0047] 40 parts by weight of modified c9 petroleum resin, 10 parts by weight of polyacrylic acid methyl resin, 150 parts by weight of modified rosin resin, 20 parts by weight of aromatic hydrocarbon oil, 4 parts by weight of styrene-butadiene rubber, 1 part by weight of 300 type antioxidant and 531 parts by weight 2 parts by weight of type anti-ultraviolet agent were added together and heated at 140°C for 2 hours, then mixed uniformly through a high-speed shear mill, and 60 parts of modified resin, 30 parts of water, and 2 parts of surfactant were mixed together and passed through a high-speed shear colloid mill to prepare into water-based modified asphalt emulsion. After the material is dehydrated, it has the properties of heat resistance, weather resistance, fatigue resistance, high bond strength and ability to withstand large loads. Water-based modified asphalt and pigments (iron oxides), fillers and sandstones are mixed in a ratio of 50:6:20:24 The ratio is mixed evenly, a...

Embodiment 2

[0053] It is basically the same as Example 1, except that water-based modified asphalt is mixed with pigments (iron oxides), fillers and sand in a ratio of 45:5:15:20, and reinforced short glass fibers (with a length of 3 ~4mm), the reinforcing fiber accounts for 2‰ of the total weight of the dry base material of the asphalt paint.

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com