Naphthyl ultrahigh-refractive-index LED packaging silicone

A technology of LED packaging and silica gel, applied in adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of optical resins such as unsatisfactory transparency, poor stability, and long polymerization induction period, and achieve visible light transmittance Good, excellent vulcanization resistance, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

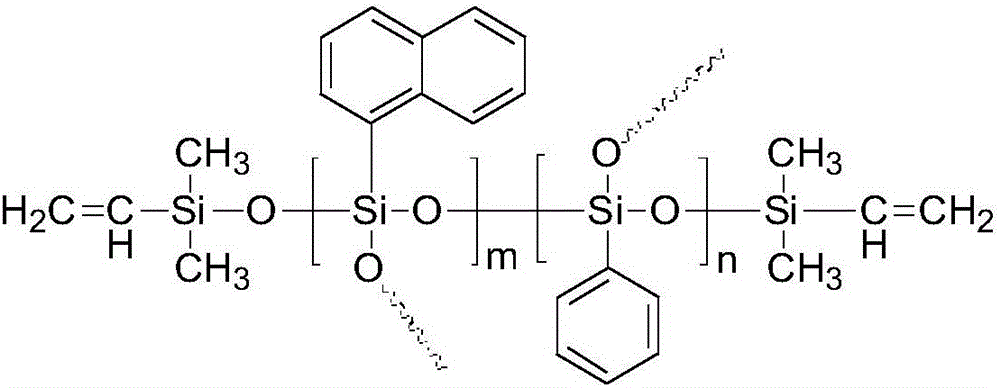

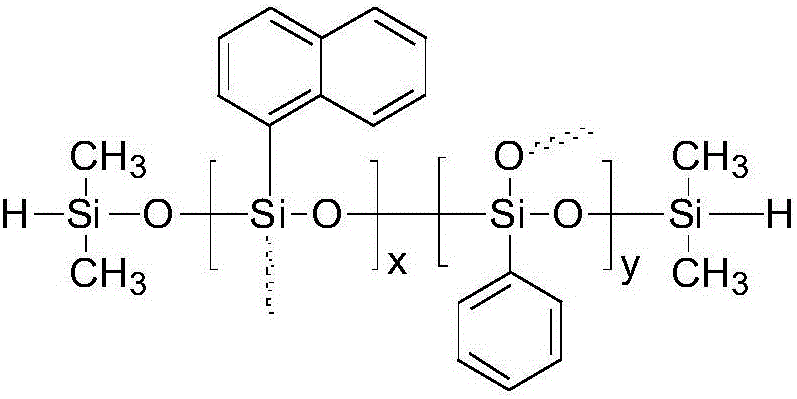

[0036] Preparation of component A: Weigh 24g of vinyl resin (m=6, n=0 in structural formula), 17g of crosslinking agent (x=0, y=3.5 in structural formula), 0.10g of inhibitor ethynyl cyclohexanol, Adhesive (n in the structural formula 1 = 2, n 2 =0,n 3 =2) 1.82g was added into the blender one by one, flushed with nitrogen, mixed and stirred evenly, and the A component was obtained.

[0037] Preparation of component B: Weigh 6 g of methylphenyl-terminated vinyl silicone oil with a viscosity of 1200 mPa.s, 2 g of vinyl resin (m=6, n=0 in the structural formula), platinum-vinyl siloxane complex ( Platinum content is 5000ppm) 0.10g, add into the mixer one by one, flush with nitrogen, mix and stir evenly, and obtain the B component.

[0038] When in use, mix the above-mentioned components A and B evenly in a weight ratio of 10:1, remove the air bubbles in the glue in a vacuum, dispense or pour glue on the parts to be packaged, and heat at 80°C for 1 hours, and then heated at 15...

Embodiment 2

[0041] Preparation of component A: Weigh 60 g of vinyl resin (m=3, n=2 in structural formula), 55 g of crosslinking agent (x=1, y=2 in structural formula), 0.15 g of inhibitor ethynyl cyclohexanol, Adhesive (n in the structural formula 1 = 2, n 2 =0,n 3 = 2) 4.00g was added into the mixer in turn, flushed with nitrogen, mixed and stirred evenly, and the A component was obtained.

[0042] Preparation of component B: Weigh 15 g of methylphenyl-terminated vinyl silicone oil with a viscosity of 500 mPa.s, 5 g of vinyl resin (m=3, n=2 in the structural formula), platinum-vinyl siloxane complex ( Platinum content is 3000ppm) 0.20g, add into the mixer one by one, flush with nitrogen, mix and stir evenly, and obtain the B component.

[0043] When in use, mix the above-mentioned components A and B evenly in a weight ratio of 10:1, remove the air bubbles in the glue in a vacuum, dispense or pour glue on the parts to be packaged, and heat at 80°C for 1 hours, and then heated at 150°C...

Embodiment 3

[0046]Preparation of component A: Weigh 38g of vinyl resin (m=8, n=0 in structural formula), 15g of crosslinking agent (x=1.5, y=0.5 in structural formula), 0.10g of inhibitor ethynyl cyclohexanol, Adhesive (n in the structural formula 1 = 2, n 2 =0,n 3 =0) 1.5g, put into the blender one by one, flush with nitrogen, mix and stir evenly to obtain the A component.

[0047] Preparation of component B: Weigh 6 g of methylphenyl-terminated vinyl silicone oil with a viscosity of 300 mPa.s, 3 g of vinyl resin (m=8, n=0 in the structural formula), platinum-vinyl siloxane complex ( Platinum content is 5000ppm) 0.10g, add into the mixer one by one, flush with nitrogen, mix and stir evenly, and obtain the B component.

[0048] When in use, mix the above-mentioned components A and B evenly in a weight ratio of 10:1, remove the air bubbles in the glue in a vacuum, dispense or pour glue on the parts to be packaged, and heat at 80°C for 1 hours, and then heated at 150°C for 3 hours.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com