Highly dispersed zwitterionic dispersant for cementing pad fluid, and preparation method thereof

A cementing prefluid and amphoteric ion technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of incomplete replacement of drilling fluid in narrow annulus, reduced sealing capacity of cement sheath, and interface cementation quality Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] It is determined that the mass ratio of the reaction monomer is AS:MA:DMDAAC=2.2:1.5:0.2, the amount of ammonium persulfate (APS) in the initiator is 1.3% of the monomer mass ratio, and the amount of reducing agent sodium bisulfite 2.0% of the monomer mass ratio, the reaction temperature was 85 °C, and the reaction time was 3 h. Add isopropanol accounting for 3% of the total amount of monomers, take it out after constant temperature for 0.5 h, and adjust its pH value to 5~6 with a pH regulator to obtain 1# zwitterionic dispersant.

[0022] Put 100 parts of clear water into the slurry cup, add 0.4 parts of viscosifier, stir and dissolve for 4 hours, then add 0.3 parts of defoamer and 5 parts of 1# amphoteric ionic dispersant in order to reach the required density of pre-liquid 45 parts of solid phase material, and 1.0 part of composite surfactant, formulated to a density of 1.2 g / cm 3 preflux. Refer to API Specification 10 B to measure the oil-based drilling fluid (den...

Embodiment 2

[0024] Determined that the mass ratio of the reaction monomer is AS:MA:DMDAAC=4.0:1.2:0.3, the amount of potassium persulfate in the initiator is 2.5% of the monomer mass ratio, and the amount of the reducing agent sodium bisulfite is 2.5% of the monomer mass ratio. 1.3% by weight, the reaction temperature was 55 °C, and the reaction time was 5 h. Add isopropanol accounting for 5% of the total amount of monomers, take it out after constant temperature for 0.5 h, adjust its pH value to 5~6 with a pH regulator, and obtain 2# zwitterionic dispersant.

[0025] Put 100 parts of clear water in the slurry cup, add 0.4 parts of viscosifier, stir and dissolve for 4 hours, then add 0.3 parts of defoamer and 5 parts of 2# zwitterionic dispersant in order to reach the required density of the front liquid 45 parts of solid phase material, and 1.0 part of composite surfactant, formulated to a density of 1.2 g / cm 3 preflux. Refer to API Specification 10 B to measure the oil-based drilling ...

Embodiment 3

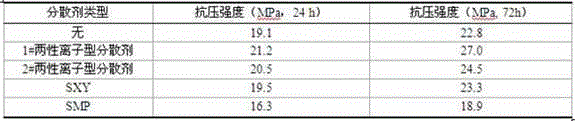

[0027] The zwitterionic dispersant, SXY, and SMP synthesized in Example 1 and Example 2 were respectively added to the cement slurry, and the formed cement stone was cured at 90°C for 24 h and 72 h to test its compressive strength. Test The results are shown in Table 5. It can be seen from Table 5 that the compressive strength of cement stone added with zwitterionic dispersant is higher than that of cement stone containing SXY or SMP.

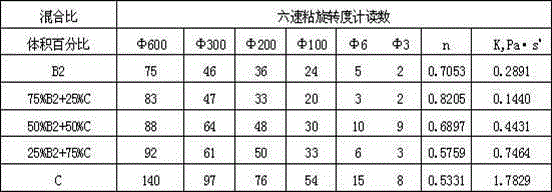

[0028] From Table 1 to Table 4, it can be seen that the pad fluid containing zwitterionic dispersant has good compatibility and dispersibility to drilling fluid and cement slurry, and the mixed slurry has no thickening and flocculation. Has good rheology.

[0029] It can be seen from Table 5 that zwitterionic dispersants with different component contents can improve the compressive strength of cement stone to varying degrees, and the 1# product has a strong ability to improve the compressive strength value of cement stone.

[0030] Table 1 Ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com