Preparation method of cement superplasticizer

A high-efficiency water reducer, water reducer technology, applied in the field of water reducer, can solve the problems of crystallized water reducer particles are too large, cannot be fully mixed, and the effect of the water reducer cannot be exerted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

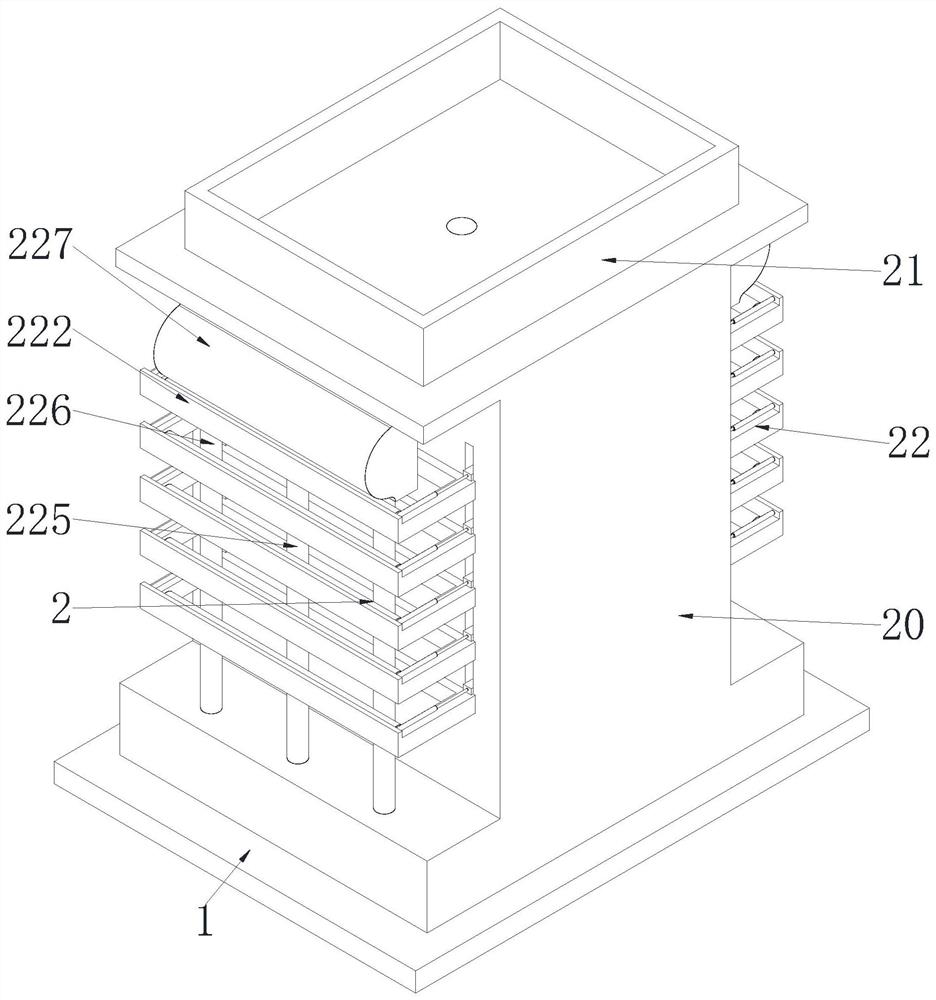

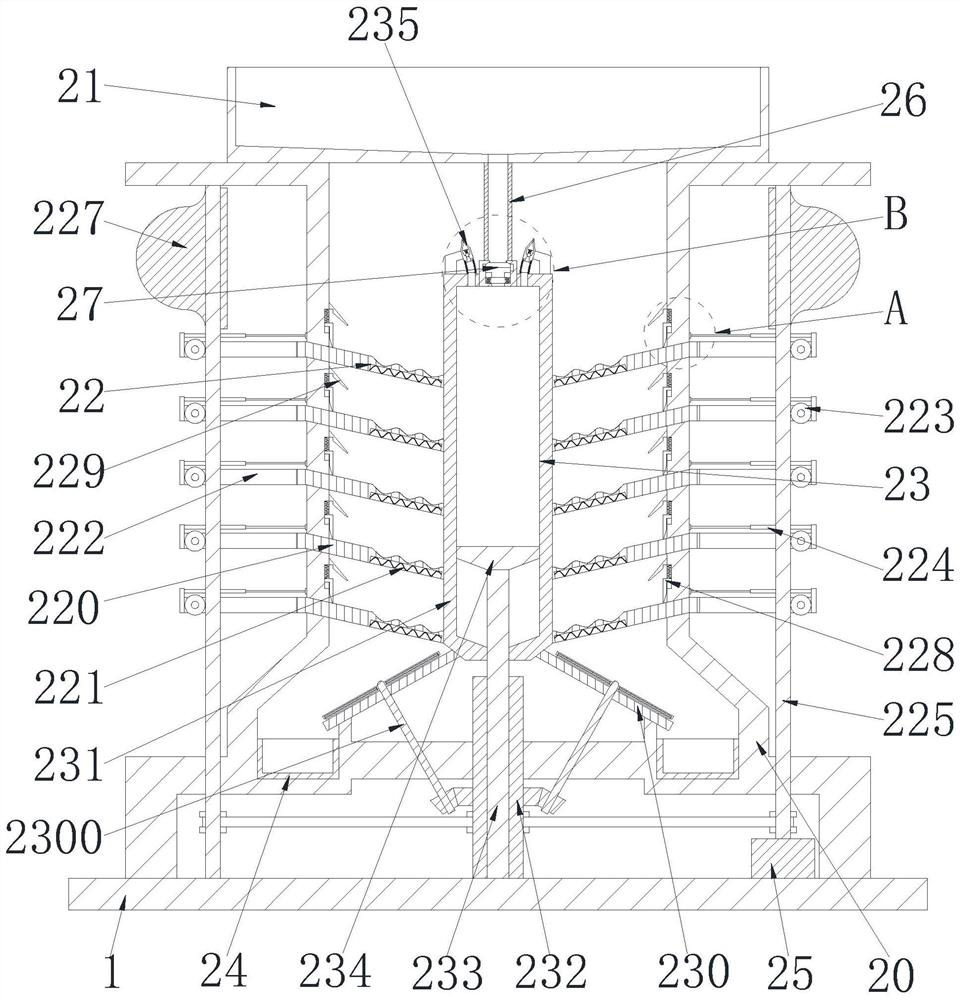

[0031] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0032] A method for preparing a high-efficiency cement water-reducing agent, which uses a preparation equipment for a high-efficiency cement water-reducing agent. The equipment for preparing a high-efficiency cement water-reducing agent includes a base 1 and a drying device 2. The specific method for the preparation of high-efficiency water reducer is as follows:

[0033] Step 1. Preparatory work: debugging the cement high-efficiency water reducer preparation equipment of the present invention;

[0034] Step 2. Extraction of liquid water reducing agent: use sulfite pulp waste liquid as raw material, first undergo biological fermentation treatment to desugar and then extract alcohol, and concentrate the alcohol waste liquid with a concentration of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com