Mn<4+> doped fluoride red light fluorescent powder for high color rendering and warm white light LED (Light Emitting Diode) and preparation method of Mn<4+> doped fluoride red light fluorescent powder

A technology of red fluorescent powder and warm white light, which is applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., and can solve unfavorable large-scale industrial production, low phosphor yield and light efficiency, and difficult control of the preparation process, etc. problems, to achieve the effects of easy industrial production, low equipment requirements, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

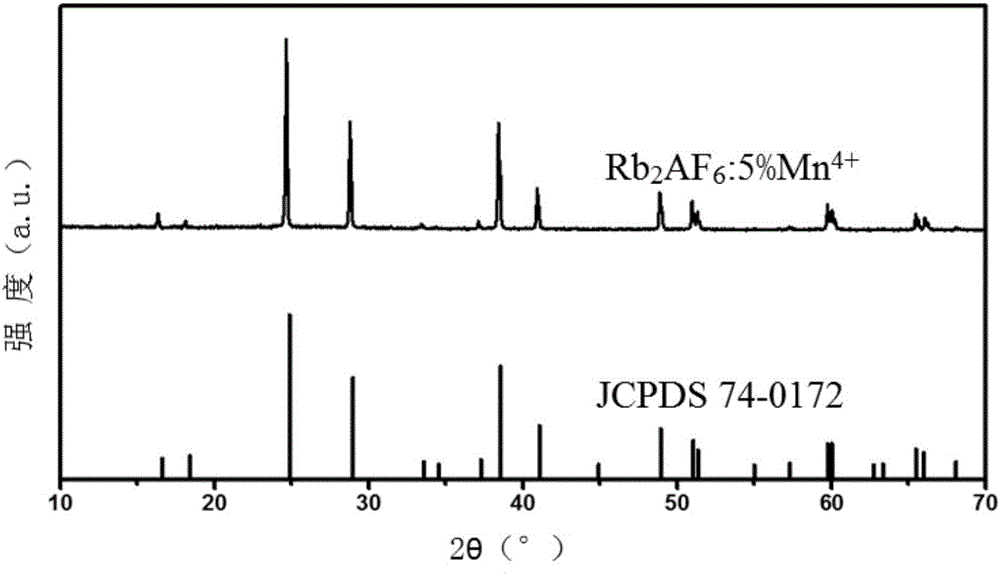

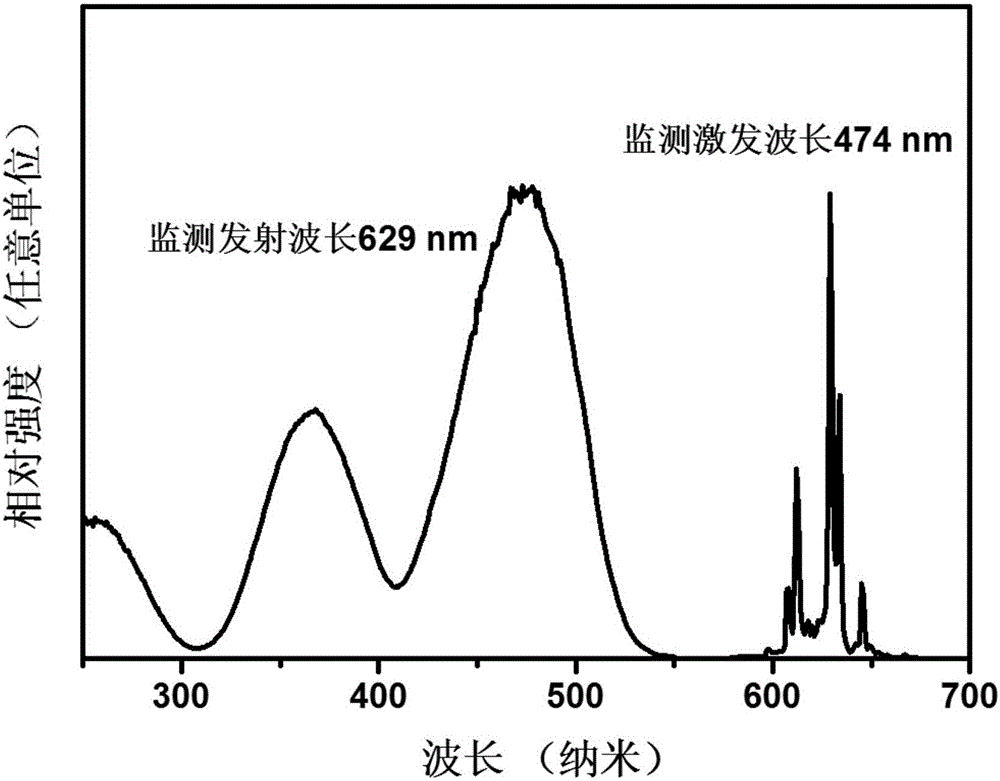

[0035] Rb 2 ZrF 6 :xMn 4+ (1.25%≤x≤20%) Preparation of Fluoride Phosphor Powder

[0036] 0.0077g K 2 MnF 6 Powder dissolved in 1.2ml H 2 O, stirred for 5 minutes (stirring speed is 1000r / min), to obtain a yellow solution; then 0.92g RbF powder and 0.383ml H 2 ZrF 6 Aqueous solution (concentration is 45wt%) joins in the yellow solution, continues stirring rapidly at room temperature for 60 minutes (stirring speed is 1000r / min), then centrifuges wash with water 3 times (centrifugal speed is 2000r / min), bakes at 80 ℃ again Dry for 6 hours to obtain the red phosphor material Rb 2 ZrF 6 :1.25%Mn 4+ , namely sample 1.

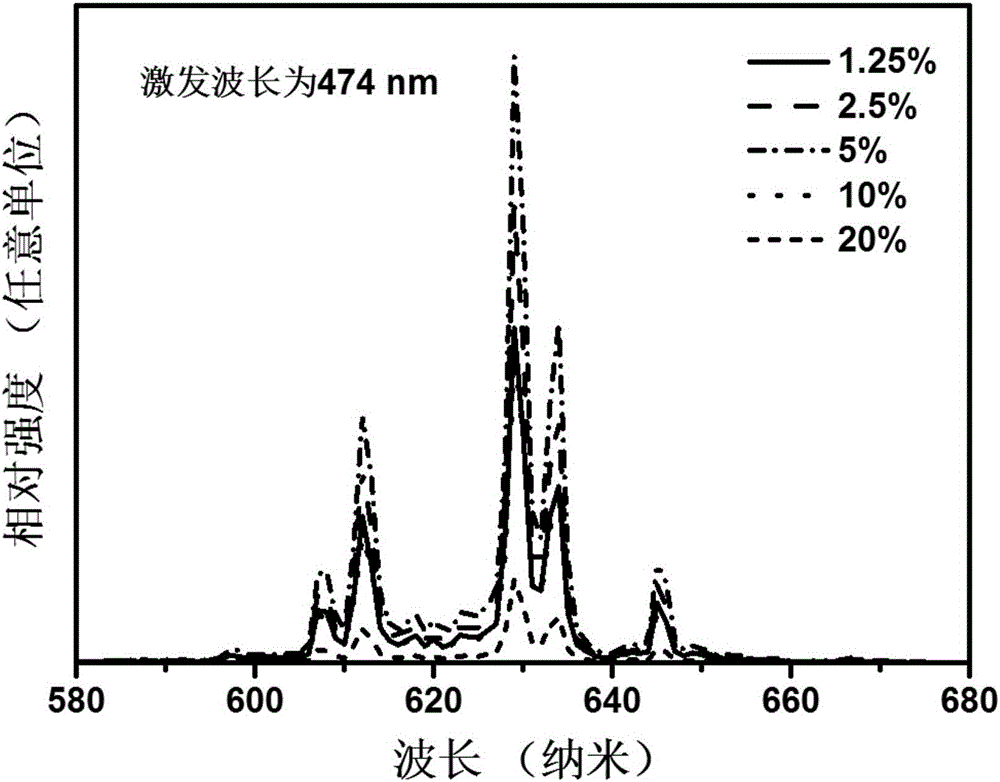

[0037] By changing the K in the raw material 2 MnF 6 The mass of different Mn 4+ Table 1 shows the specific ratio of raw materials and the properties of the prepared phosphors for samples 2 to 5 with doping amounts.

[0038] Table 1Rb 2 ZrF 6 :xMn 4+ Raw material ratio and relative luminous intensity of red phosphor

[0039]

[0040]

[0041] ...

Embodiment 2

[0047] Rb 2 TiF 6 :xMn 4+ (1.25%≤x≤20%) Preparation of Fluoride Phosphor Powder

[0048] 0.0077g K 2 MnF 6 Powder dissolved in 1.5ml H 2 O, stirred for 5 minutes (stirring speed is 1000r / min), to obtain a yellow solution; then 1.306g RbF powder and 0.245ml H 2 TiF 6 Aqueous solution (concentration: 50wt%) was added to the yellow solution, continued stirring at room temperature for 60 minutes (stirring speed was 1000r / min), then centrifugally washed with water for 3 times (centrifugal speed was 2000r / min), and then dried at 80°C 6h, get the red phosphor material Rb 2 TiF 6 :1.25%Mn 4+ , namely sample 6.

[0049] By changing the K in the raw material 2 MnF 6 The mass of different Mn 4+ Table 2 shows the specific ratio of raw materials and the properties of prepared phosphors for samples 7-10 with doping amount.

[0050] Table 2Rb 2 TiF 6 :xMn 4+ Raw material ratio and relative luminous intensity of red phosphor

[0051]

[0052] It can be seen from Table 2 t...

Embodiment 3

[0057] Rb 2 TiF 6 :10%Mn 4+ Encapsulated LED

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com