Method for preparing oil-soluble selenium or telluride semiconductor quantum dot without phosphine through dissolving chalcogenide oxide by alkanethiol

A technology of alkyl thiols and oxides, applied in chemical instruments and methods, nanotechnology, nano optics, etc., can solve problems such as long reflow time, unfavorable industrial production of quantum dots, and reaction temperature limitations, etc., to achieve good performance, The effect of reducing the preparation cost and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

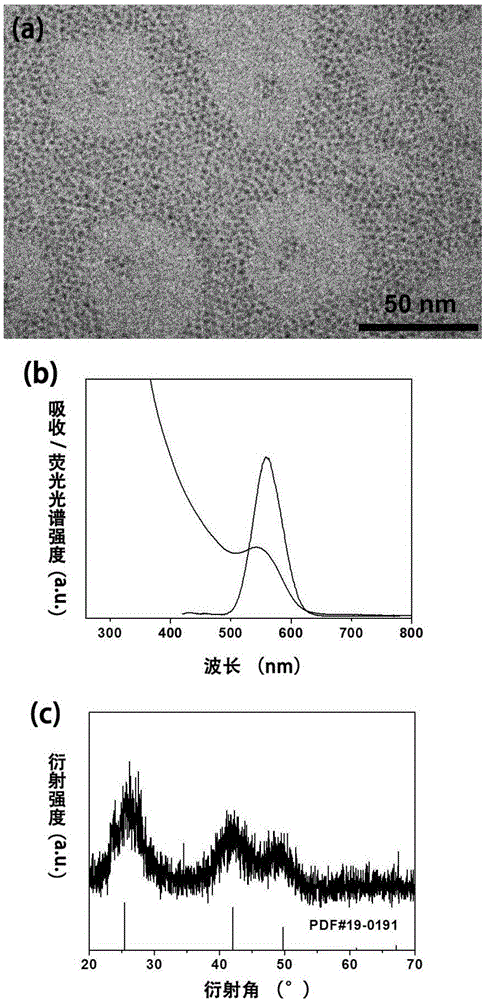

[0036] 0.11g (1mmol) SeO 2 The powder was added to 2 mL of dodecyl mercaptan, the system was vacuumed for 10 minutes, and then nitrogen gas was introduced, and the operation was repeated 3 times. Stir at room temperature under the protection of nitrogen until SeO 2 The powder is completely dissolved to obtain a light yellow solution, which is used as a selenium precursor to synthesize semiconductor quantum dots from selenide.

[0037] 0.27g (1mmol) Cd (AC) 2 2H 2 O was added to a mixed solution of 1 mL oleic acid and 9 mL octadecene. The reaction system was evacuated and nitrogen was blown 3 times, 10 minutes each time. Then heated to 100°C under vacuum for 30 minutes, until Cd(AC) 2 2H 2 O dissolved. then in N 2 Under the protection of air, the solution was heated to 150°C, the selenium precursor prepared earlier was added, and the reaction was continued at 150°C for 10 minutes, as figure 1 As shown, CdSe semiconductor quantum dots were obtained.

Embodiment 2

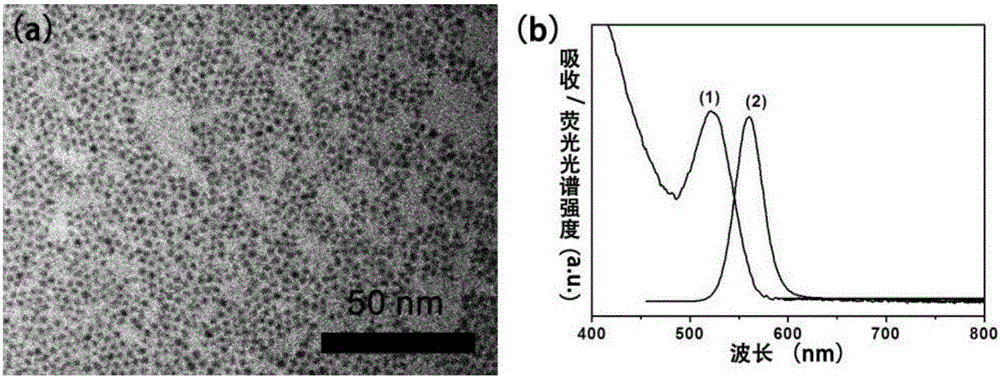

[0039] 0.06g (0.5mmol) SeO 2 The powder was added to 5 mL of dodecyl mercaptan, the system was vacuumed for 10 minutes, and then nitrogen gas was introduced, and the operation was repeated 3 times. Stir at room temperature under the protection of nitrogen until SeO 2 The powder is completely dissolved to obtain a light yellow solution, which is used as a selenium precursor to synthesize semiconductor quantum dots from selenide.

[0040] 0.14g (0.5mmol) Cd (AC) 2 2H 2 O was added to a mixed solution of 1 mL oleic acid and 9 mL octadecene. The reaction system was evacuated and nitrogen was blown 3 times, 10 minutes each time. Then heated to 100°C under vacuum for 30 minutes, until Cd(AC) 2 2H 2 O dissolved. then in N 2 Under gas protection, the temperature of the solution was raised to 200° C., the previously prepared selenium precursor was added, and the reaction was continued at 200° C. for 30 minutes to obtain CdSe semiconductor quantum dots.

Embodiment 3

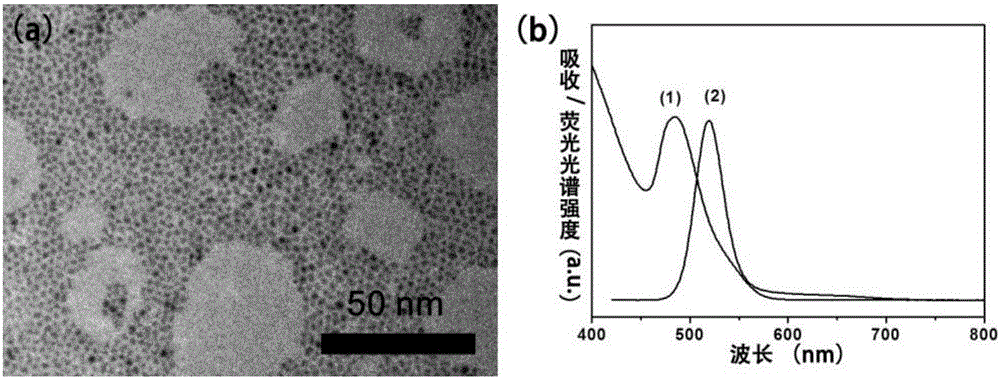

[0042] 0.16g (1mmol) TeO 2 The powder was added to 2 mL of dodecyl mercaptan, the system was vacuumed for 10 minutes, and then nitrogen gas was introduced, and the operation was repeated three times. Stirring at 100°C under the protection of nitrogen, the TeO 2 The powder was completely dissolved to obtain an orange solution, which was cooled to room temperature. This solution is used as a tellurium precursor for the synthesis of semiconductor quantum dots.

[0043] 0.32g (1.4mmol) CdCl 2 2H 2 O was added to a mixed solution of 5 mL oleylamine and 5 mL octadecene. The reaction system was evacuated and nitrogen was blown 3 times, 10 minutes each time. Then heated to 100°C under vacuum for 30 minutes, the CdCl 2 2H 2 O dissolved to give a milky white solution. then in N 2 Inject the previously prepared tellurium precursor under gas protection, and stop heating after 10 minutes of reaction, such as figure 2 As shown, CdTe semiconductor quantum dots with green fluoresce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com