Industrial storage and reutilization method of anaerobic ammonia oxidizing bacteria

A kind of anammox bacteria and anaerobic ammonium oxidation technology, applied in the direction of anaerobic digestion treatment, bacteria, preserved microorganisms, etc., to achieve the effect of simple control conditions, few control factors, and reliable recovery of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

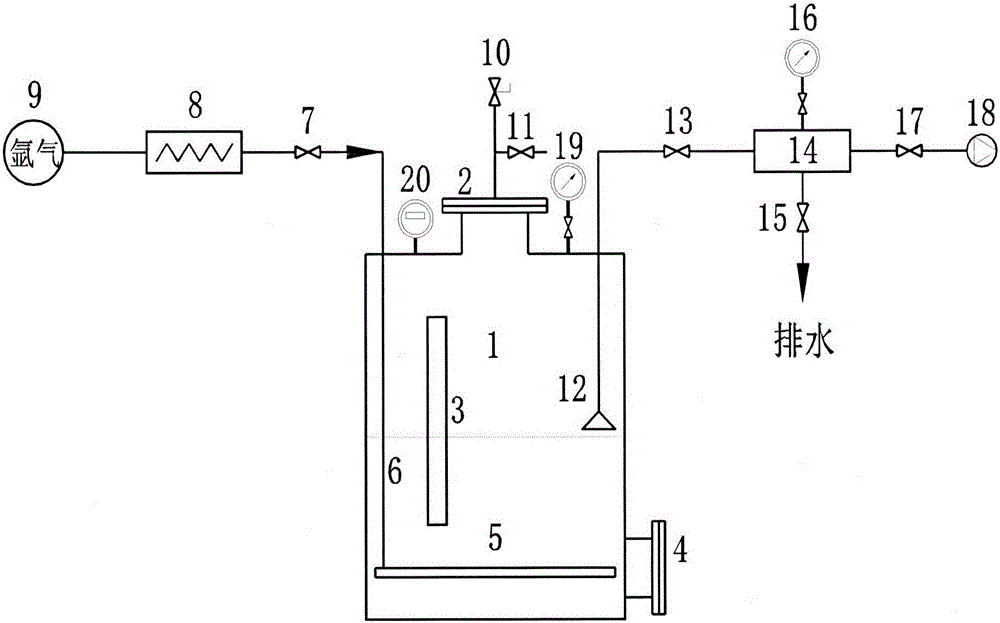

[0041] The anammox strain storage container in the present embodiment is as figure 1 shown. The strain storage container 1 is a cylindrical stainless steel tank with an effective volume of 1000L. The top of the strain storage container 1 is provided with a flange feed port 2, and the bottom is provided with a flange discharge port 4. The tank body of the strain storage container 1 is provided with a plate frame sight glass 3, which can observe the liquid level and the mud level in the tank. The inner bottom of the strain storage container 1 is provided with a ring-shaped microporous aeration pipe 5, which is connected to a high-purity argon gas source 9 through an air inlet pipe 6, and an air inlet valve 7 and a gas heating device 8 are arranged on the air inlet pipe 6 . The middle part of the strain storage container 1 is provided with a drain pipe 12 on which a drain ball valve 13 is arranged. A vacuum pumping system is provided on the drain pipe 12, including a negative...

Embodiment 2

[0057] The anammox strain storage container in the present embodiment is as figure 1 shown. The strain storage container 1 is a cylindrical pressure-resistant glass fiber reinforced plastic tank with an effective volume of 1000L. The top of the strain storage container 1 is provided with a flange feed port 2, and the bottom is provided with a flange discharge port 4. The tank body of the strain storage container 1 is provided with a plate frame sight glass 3, which can observe the liquid level and the mud level in the tank. The inner bottom of the strain storage container 1 is provided with a ring-shaped microporous aeration pipe 5, which is connected to a high-purity argon gas source 9 through an air inlet pipe 6, and an air inlet valve 7 and a gas heating device 8 are arranged on the air inlet pipe 6 . The middle part of the strain storage container 1 is provided with a drain pipe 12 on which a drain ball valve 13 is arranged. A vacuum pumping system is provided on the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com