Method for improving production capacity of acid producing bacteria by adopting Vc two-step fermentation

A production capacity, two-step fermentation technology, applied in fermentation and other directions, can solve problems such as difficulty in further improving production capacity, unbalanced growth of acid-producing bacteria and associated bacteria, and suppression of the number and activity of acid-producing bacteria. The effect of production efficiency, short fermentation cycle, standardized management and regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

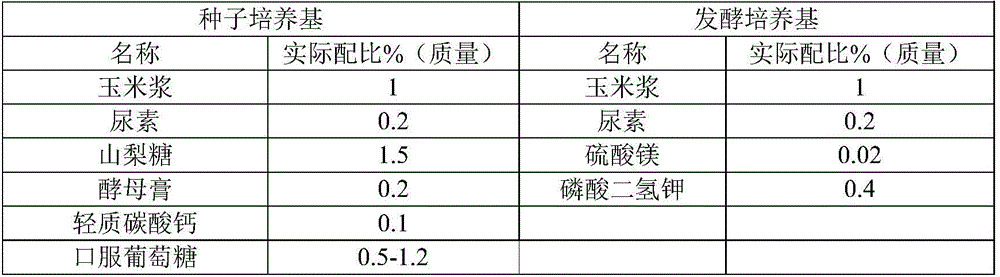

Method used

Image

Examples

Embodiment 1

[0024] (1) choose 5L fermenter, inject 3L glucose mass content and be the seed culture medium of 0.5%, insert 150ml concentration and be 2 * 10 8 CFU / ml of Bacillus megaterium suspension was used as companion bacteria, and the concentration of companion bacteria reached 3.6×10 8 CFU / ml, and then ultrasonically disrupted at 25KHz to obtain active protein solution.

[0025] (2) Take 100ml of the above-mentioned active protein solution, insert it into a 20L fermentation tank containing 15L of fermentation medium, and then insert 400ml of it into a bacterium concentration of 3×10 9 CFU / ml suspension of acid-producing bacteria (acid-producing bacteria is ketogenic cologne), fermented until the bacterial concentration reaches 4.5×10 9 CFU / ml to obtain the acidogenic bacteria fermentation seed liquid. (3) Get 15L of the above-mentioned acidogenic bacteria fermentation seed solution and insert it into a 500L fermenter containing 300L of fermentation medium and 1.5L of the active pro...

Embodiment 2

[0028] (1) Select a 5L fermenter, inject 3L of seed culture medium with a glucose mass content of 0.5%, and insert 150ml of bacteria with a concentration of 2×10 8 CFU / ml of Bacillus megaterium suspension was used as companion bacteria, and the concentration of companion bacteria reached 3.6×10 8 CFU / ml. 25KHz ultrasonic crushing to obtain active protein liquid.

[0029] (2) Take 100ml of the active protein solution obtained above, insert it into a 20L fermenter containing 15L of fermentation medium, and then insert 400ml of it into a bacterium concentration of 3×10 9 CFU / ml suspension of acid-producing bacteria (acid-producing bacteria is ketogenic cologne), fermented until the bacterial concentration reaches 4.5×10 9 CFU / ml to obtain the acidogenic bacteria fermentation seed liquid.

[0030] (3) Take 15L of the above-mentioned acidogenic bacteria fermentation seed liquid and insert it into a 500L fermenter containing 300L fermentation medium and 1.5L of the active protein...

Embodiment 3

[0033] (1) Choose a 5L fermenter, inject 3L of a seed medium with a glucose mass content of 0.6%, and insert 200ml of a concentration of 3 × 10 8 CFU / ml of Bacillus cereus suspension was used as companion bacteria, and the concentration of companion bacteria reached 5.5×10 8 CFU / ml. 25KHz ultrasonic crushing to obtain active protein liquid.

[0034] (2) Get 100ml of the active protein solution obtained above, insert it into a 20L fermentation tank containing 15L of fermentation medium, and then insert 400ml of it with a concentration of 2.5×10 9 CFU / ml suspension of acid-producing bacteria (acid-producing bacteria is ketogenic cologne), fermented until the bacterial concentration reaches 4×10 9 CFU / ml to obtain the acidogenic bacteria fermentation seed liquid.

[0035] (3) Take 15L of the above-mentioned acidogenic bacteria fermentation seed solution and insert it into a 500L fermenter containing 300L of fermentation medium and 1.5L of the active protein solution obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com