Space stacking light beam distributed phase delayer and speckle elimination method thereof

A phase retarder, stacking technology, applied in optics, instruments, optical components, etc., can solve the problems of high manufacturing cost and large structure, and achieve the effects of low cost, simple device structure and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

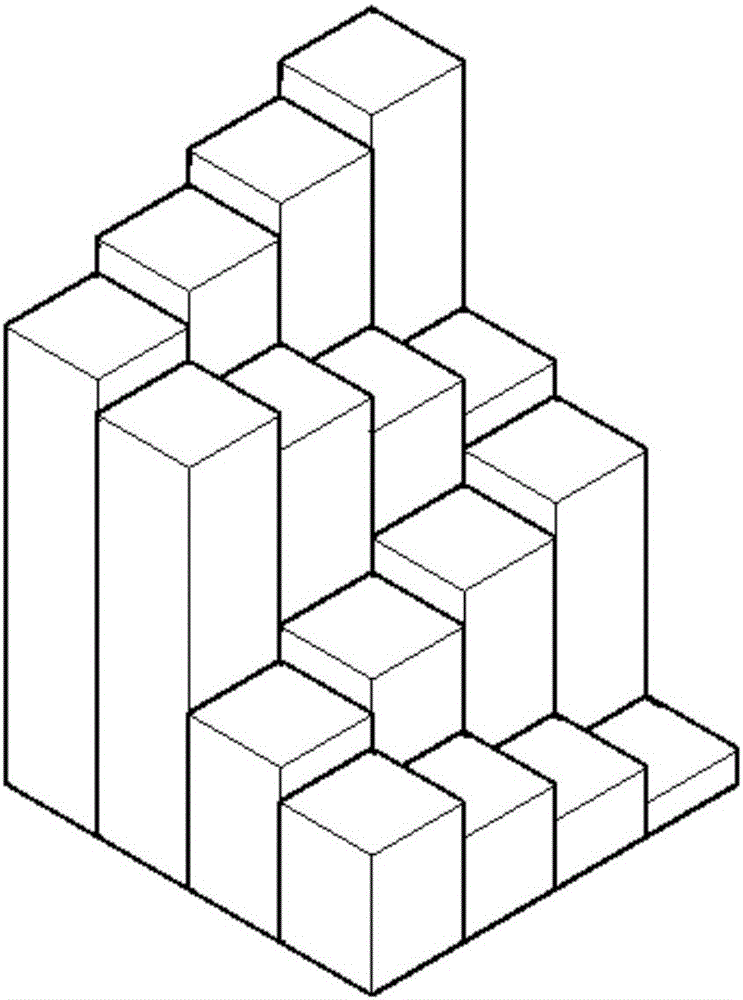

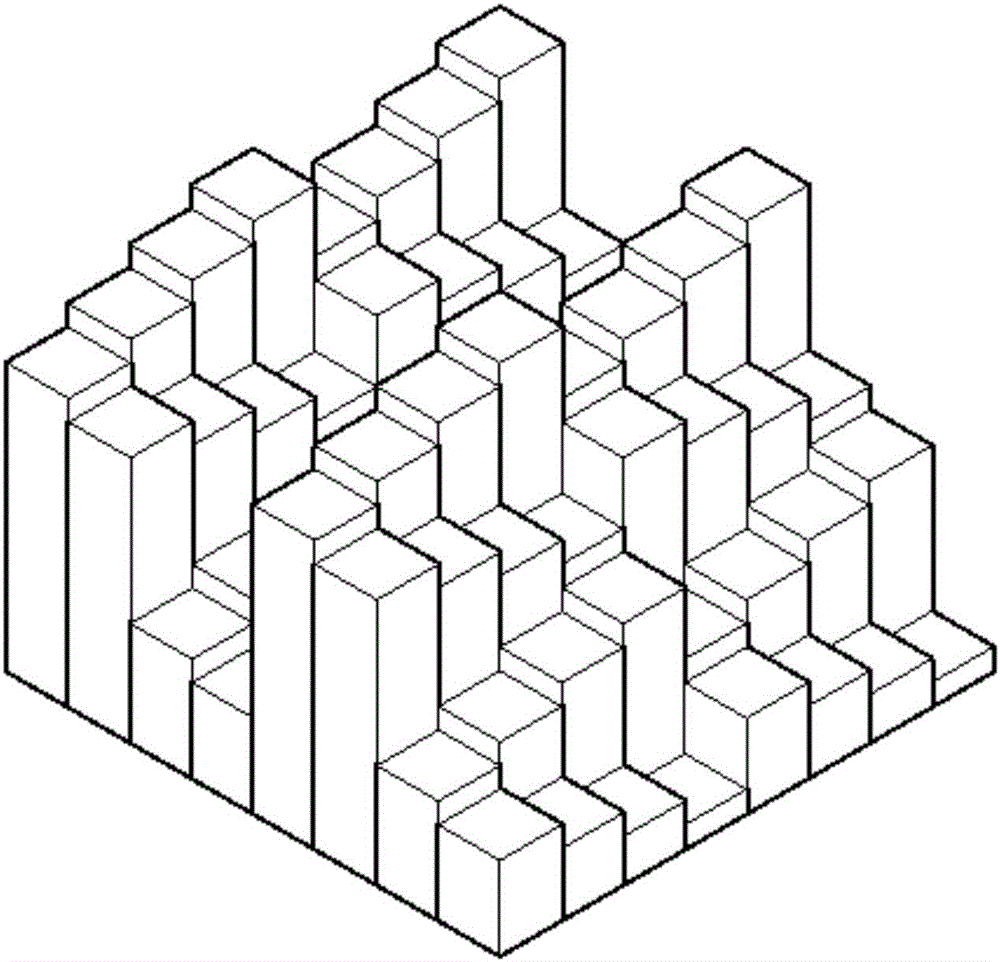

[0018] Such as figure 1 , 2 As shown, a two-dimensional space-stacked beam distributed phase retarder, wherein: the space-stacked beam distributed phase retarder is a polymer micro-processing element. Taking the SU8 photoresist micromachining element as an example, its structure is: an m×n matrix composed of SU8 photoresist micromachining elements with a certain height difference (see figure 1 ), m=n=4 in this embodiment, the polymer microprocessing element itself is a two-dimensional phase modulator, which can directly realize phase modulation in two-dimensional spatial distribution. The described two-dimensional polymer microfabricated element repeats 2 * 2 times speckle elimination device (see figure 2 ), into an 8×8 matrix.

[0019] A speckle elimination method using a two-dimensional space stacked beam distributed phase retarder, the steps of which are: expand the laser beam emitted by the laser light source, and pass through the 4×4 polymer micro-processing component...

Embodiment 2

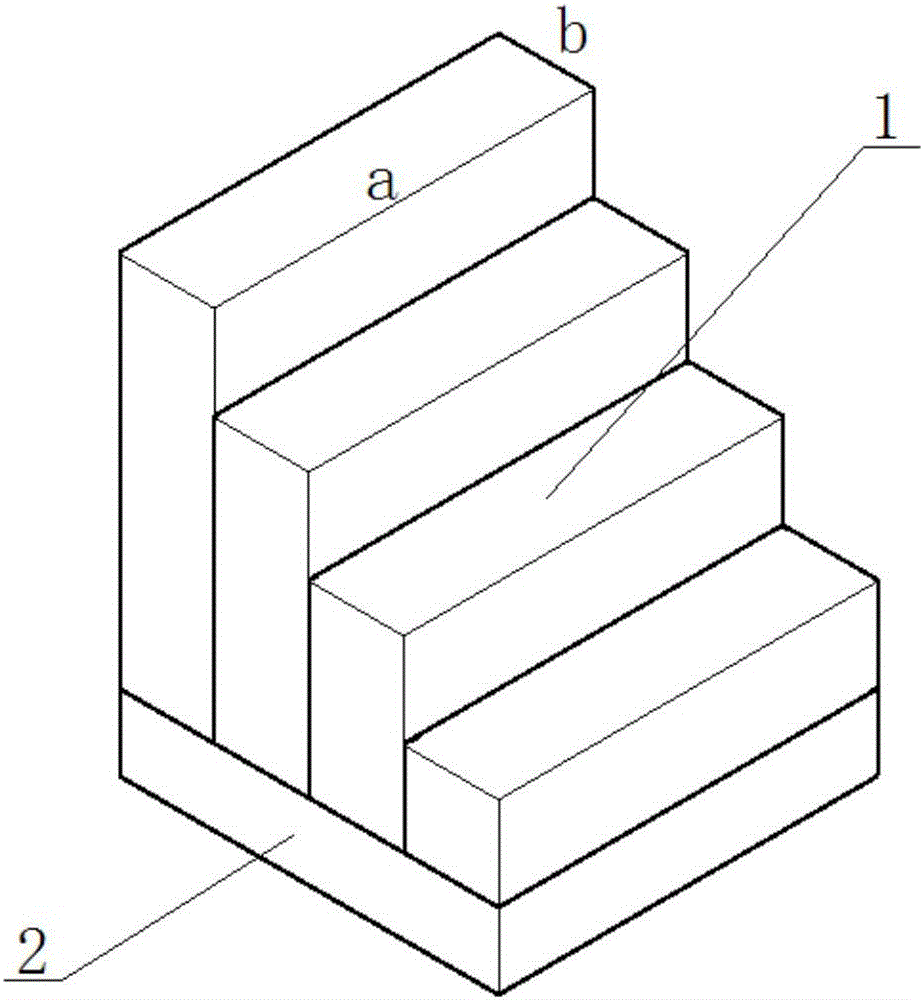

[0022] Such as image 3 , 4 As shown, a one-dimensional space-stacked beam distributed phase retarder, wherein: the space-stacked beam distributed phase retarder is a plurality of machined light-transmitting elements whose refractive index is not equal to the refractive index of air, Its structure is: machined light-transmitting elements with a certain height difference and a refractive index not equal to the refractive index of air are bonded together.

[0023] The machined light-transmitting element is, for example, glass. It consists of a glass layer 1 and a glass base 2 with a certain height difference (see image 3 ), the present embodiment is 4 layers. The length of each layer is a, the width is b, and a=4b is taken here, and then the one-dimensional machined light-transmitting elements are superimposed and assembled (see Figure 4 ), so as to realize the phase modulation of two-dimensional spatial distribution.

[0024] A speckle elimination method using a one-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com