Anode material for lithium sulfur batteries and method for preparing anode material

A lithium-sulfur battery and cathode material technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problem of active sulfur loss and other problems, and achieve the effects of preventing volume expansion, increasing capacity, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

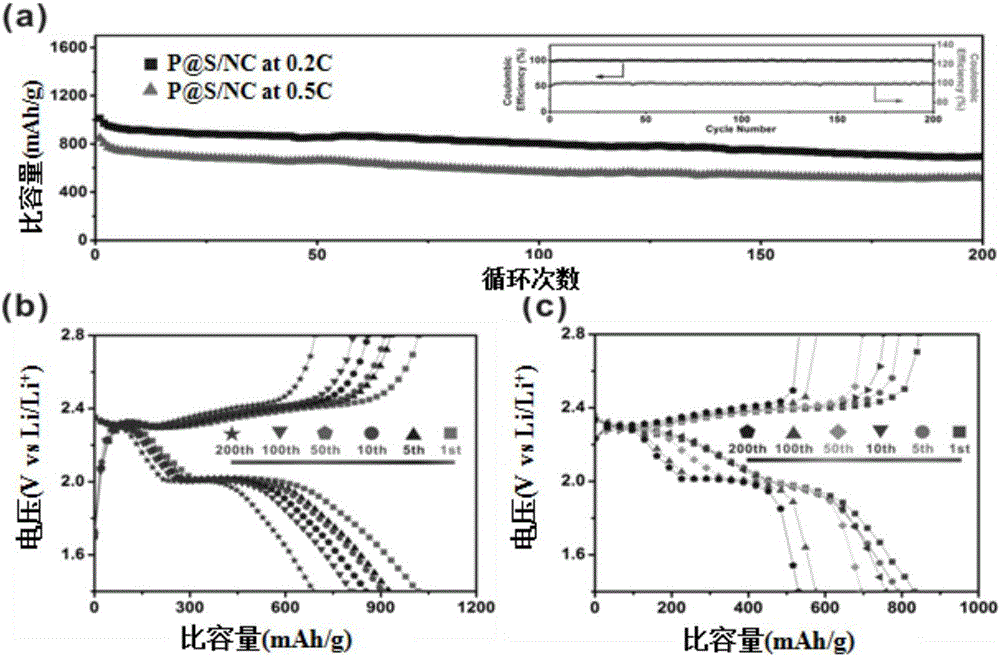

[0035] A lithium-sulfur battery cathode material, the preparation method of which comprises the following steps:

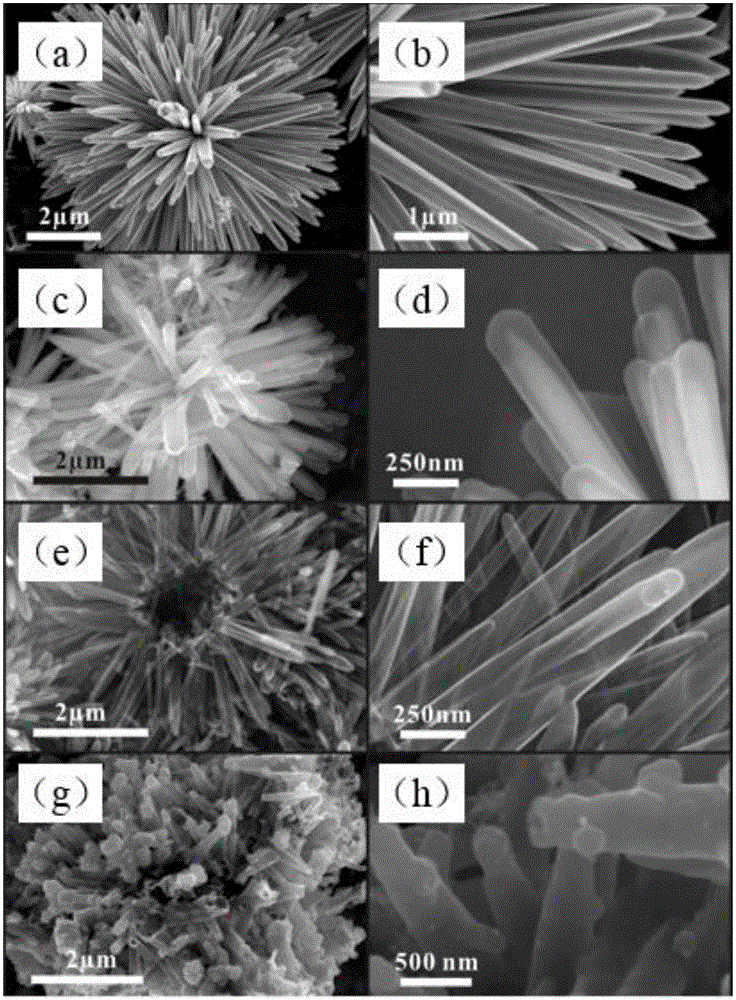

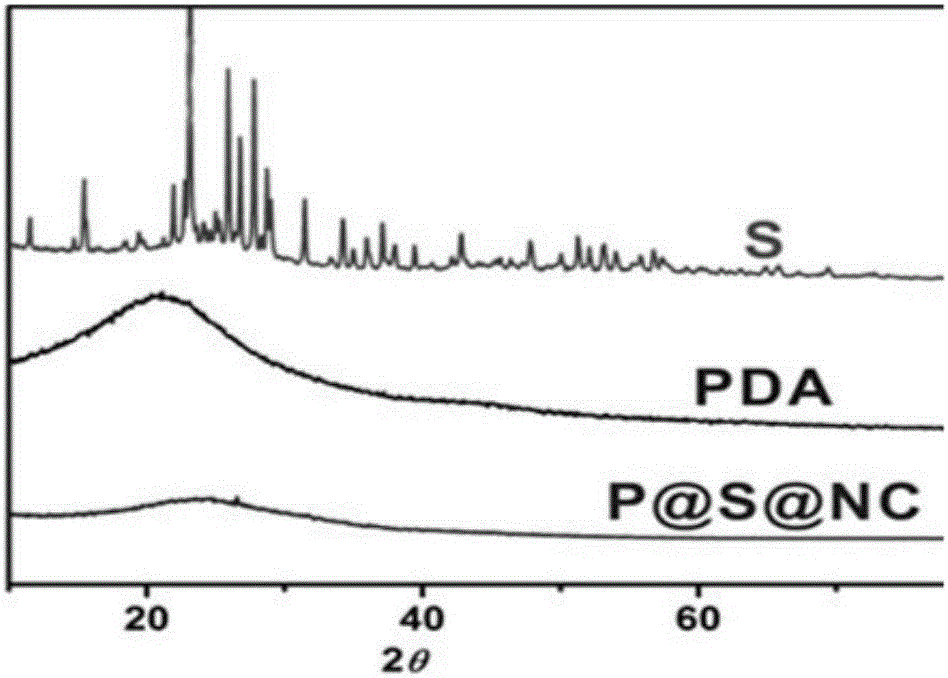

[0036] 1) First weigh 19.8g of zinc acetate dihydrate and dissolve it in 300ml of water. Take another 30.6g of sodium hydroxide and dissolve it in 255ml of water. After cooling, mix and stir the two solutions. After the mixed solution is clarified, put it in the reaction kettle , heated to 90°C for 20 minutes, removed, filtered and dried to obtain flower-shaped zinc oxide (flower-shaped ZnO);

[0037] 2) Put 1g of mesoporous pore-forming agent P123 and 1g of flower-shaped zinc oxide into 500ml of water for ultrasonic dispersion for 15min, then add 0.6g of Tris, stir for 20min, then add 1g of dopamine hydrochloride, stir for 12h Mixing coating reaction (temperature is 24°C), suction filtration and drying to obtain solid product I;

[0038] 3) Dissolve 1g of solid product I in 500ml of water, add 0.05g of microporous template agent SDS and mix well by ultrasonicati...

Embodiment 2

[0044] A lithium-sulfur battery cathode material, the preparation method of which comprises the following steps:

[0045] 1) First weigh 13.2g of zinc acetate dihydrate and dissolve it in 200ml of water. Take another 20.4g of sodium hydroxide and dissolve it in 170ml of water. After cooling, mix and stir the two solutions. After the mixed solution is clarified, put it in the reaction kettle , heated to 90°C for 20 minutes, removed, filtered and dried to obtain flower-shaped zinc oxide (flower-shaped ZnO);

[0046] 2) Put 1g of mesoporous template agent P123 and 1g of flower-like zinc oxide into 500ml of water for ultrasonic dispersion for 15min, then add 0.6g of Tris, stir for 20min, then add 1g of dopamine hydrochloride, stir for 13h to mix Coating reaction (temperature is 24°C), suction filtration and drying to obtain solid product I;

[0047] 3) Dissolve 1g of solid product I in 500ml of water, add 0.05g of microporous template agent SDS and ultrasonically mix for 15min, the...

Embodiment 3

[0053] A lithium-sulfur battery cathode material, the preparation method of which comprises the following steps:

[0054] 1) First weigh 6.6g of zinc acetate dihydrate and dissolve it in 100ml of water. Take another 10.2g of sodium hydroxide and dissolve it in 85ml of water. After cooling, mix and stir the two solutions. After the mixed solution is clarified, put it in the reaction kettle , heated to 90°C for 20 minutes, removed, filtered and dried to obtain flower-shaped zinc oxide (flower-shaped ZnO);

[0055] 2) Put 1g of mesoporous pore-forming agent P123 and 1g of flower-like zinc oxide into 500ml of water for ultrasonic dispersion for 15min, then add 0.6g of Tris, stir for 20min, then add 1g of dopamine hydrochloride, stir for 13h Mixing coating reaction (temperature is 23°C), suction filtration and drying to obtain solid product I;

[0056] 3) Dissolve 1g of solid product I in 500ml of water, add 0.05g of microporous template agent SDS and ultrasonically mix for 15min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com