A kind of preparation method and application of hollow spherical nickel sulfide positive electrode material

A positive electrode material, nickel sulfide technology, applied in the direction of battery electrodes, electrochemical generators, structural parts, etc., to improve cycle performance, increase initial charge and discharge capacity, and solve the effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Prepare 1.5mM Na 2 The ethylene glycol solution of S;

[0024] (2) Prepare 1mM NiCl 2 ·6H 2 Ethylene glycol solution of O;

[0025] (3) Dissolve 0.3g of glucose in 2ml of distilled water to obtain a glucose solution

[0026] (4) the glucose solution that step (3) obtains and the NiCl that 45ml step (2) obtains 2 ·6H 2 The ethylene glycol solution of O was mixed evenly,

[0027] (5) 30ml of Na obtained in step (1) 2 The ethylene glycol solution of S was slowly added dropwise to the mixed solution obtained in step (4), stirred vigorously for 10 minutes to mix evenly, and reacted hydrothermally at 180°C for 8 hours,

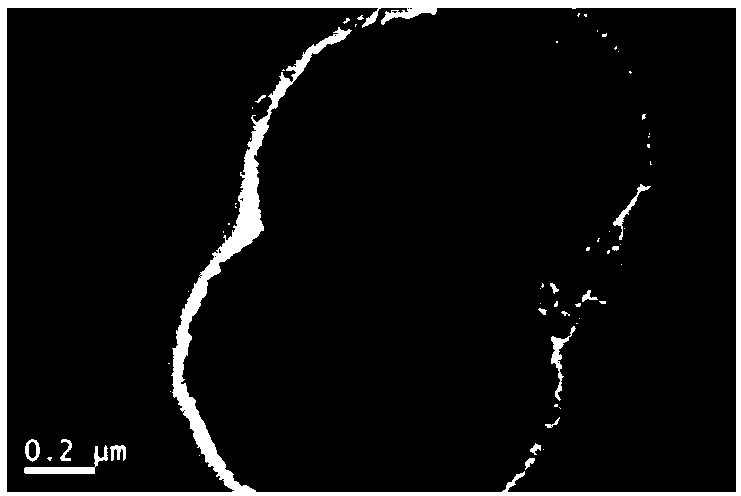

[0028] (6) Centrifuge the reaction system in step (6), wash the filter cake three times with distilled water and twice with ethanol, then dry it at 60°C for 24 hours, and then sinter at 500°C for 2 hours to obtain a hollow spherical nickel sulfide positive electrode material , TEM pictures are attached figure 1 as shown,

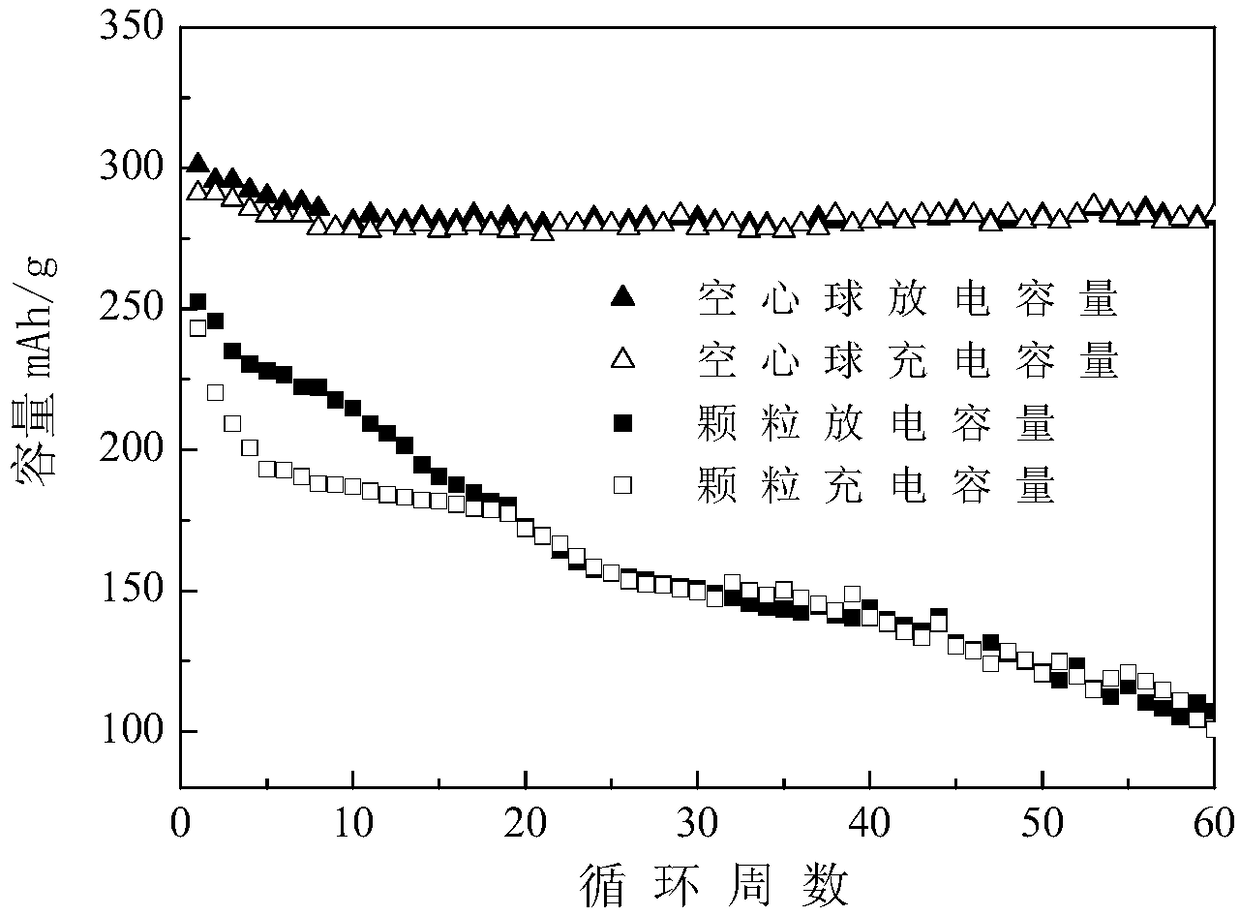

[0029] Wherein, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com