Porous aluminum-foil cathode, preparation method of porous aluminum-foil cathode and lithium secondary battery

A lithium secondary battery, aluminum foil technology, applied in the direction of secondary batteries, lithium storage batteries, battery electrodes, etc., can solve the problems of aluminum foil volume expansion, electrolyte compatibility, affecting charge and discharge efficiency, cycle performance and safety performance, etc. The effect of decomposition, improvement of stability and safety, and improvement of charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of a porous aluminum foil negative electrode, comprising the following steps:

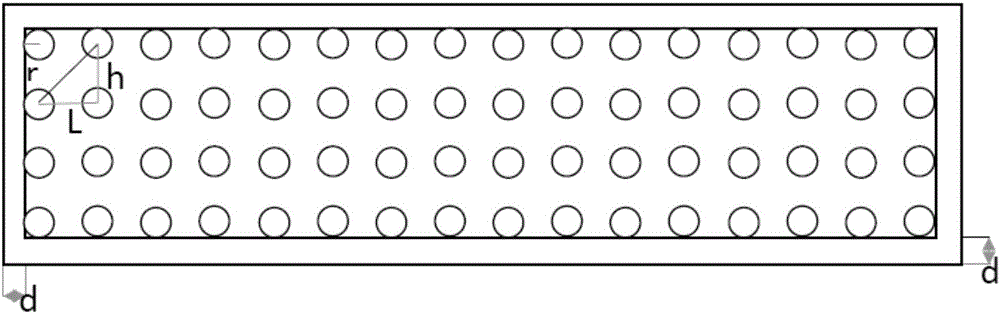

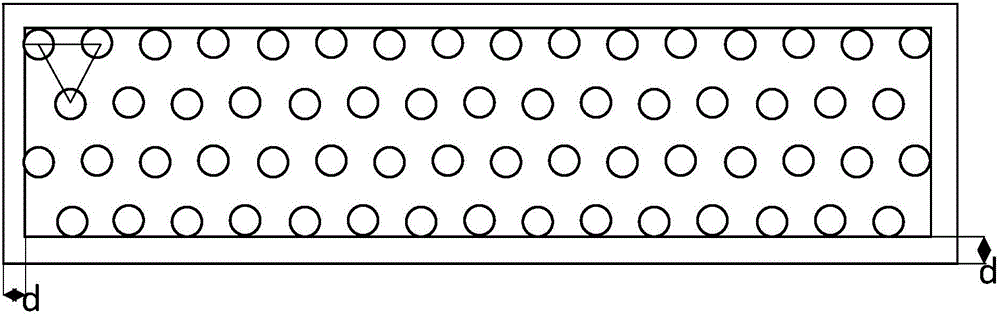

[0053] (1) The aluminum foil with a thickness of 50 microns is designed according to the design parameters that the area of the holes in each minimum unit is 25%, the diameter of the holes is 1 mm, the hole shape is a round hole, and the distance between the edge of the outermost hole and the edge of the aluminum foil is 2 mm, The porous aluminum foil is processed and manufactured by mechanical molding, and the burrs are removed by purging with compressed air;

[0054] (2) The porous aluminum foil was then immersed in an aqueous solution containing 20% polyvinylpyrrolidone for 10 minutes, and then the above-mentioned porous aluminum foil was placed in a sintering furnace filled with nitrogen and heated to 400°C at a rate of 3°C / min, and heated to 400°C at a rate of 3°C / min. The porous aluminum foil negative electrode can be obtained by carbonization treatment at a co...

Embodiment 2-38

[0061] Referring to the specific steps of Embodiment 1, different Embodiments 2-38 can be obtained by adjusting the relevant parameters. Specific embodiment parameters and test results are shown in Table 1:

[0062] Table 1

[0063]

[0064]

[0065]

Embodiment 39

[0067] A preparation method of a porous aluminum foil negative electrode, comprising the following steps:

[0068] (1) The aluminum foil with a thickness of 20 microns is designed according to the design parameters that the area ratio of the holes in each smallest unit is 25%, the diameter of the holes is 1 mm, the shape of the holes is round holes, and the distance between the edge of the outermost hole and the edge of the aluminum foil is 2 mm, The porous aluminum foil is processed and manufactured by mechanical molding, and the burrs are removed by purging with compressed air;

[0069] (2) The porous aluminum foil was then soaked in an aqueous solution containing 20% polyvinylpyrrolidone for 10 minutes, and then the above-mentioned porous aluminum foil was placed in a sintering furnace with an inert gas or a reducing gas and heated to 400°C at a rate of 3°C / min , and carbonized at a constant temperature of 400 °C for 4 hours to obtain a porous aluminum foil negative elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com