Proton exchange membrane non-platinum catalyst using peanut as raw material and preparation method thereof

A technology of proton exchange membrane and platinum catalyst, which is applied in the direction of fuel cells, electrochemical generators, electrical components, etc., can solve the problems that hinder the application of proton exchange membrane fuel cells, low reserves, high price of platinum, etc., and achieve excellent oxygen storage/ Effect of release ability, improvement of oxygen reduction activity, enrichment of nitrogen and carbon elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A kind of preparation method of the cathode non-platinum catalyst of proton exchange membrane fuel cell with peanut as raw material, comprises the following steps:

[0019] 1) Mix peanuts with water at a ratio of 100 g:100-1000 mL and make peanut slurry;

[0020] 2) Add cerium oxide precursor and iron precursor and stir evenly;

[0021] The mass ratio of peanut, cerium oxide precursor and iron precursor is 1-100:1-50:1-35, and the molar ratio of carbon, nitrogen, iron and cerium oxide in the catalyst is 1-10:0.3-3:0.1 -5:0.1-5;

[0022] The cerium oxide precursor is cerium nitrate or ammonium cerium nitrate; the iron precursor is ferric nitrate, ferric sulfate, ferric chloride, ferrocene, ferric hydroxide, ferric sulfide, ferric halide or ferric perchlorate;

[0023] 3) Add a sodium hydroxide solution with a concentration of 0.5-15mol / L and stir evenly to obtain a mixed solution;

[0024] 4) Put the above mixed solution into a high-pressure reactor and seal it, and h...

Embodiment 1

[0027] A method for preparing a proton exchange membrane fuel cell cathode catalyst with good oxygen reduction activity, the specific steps are:

[0028] 1. Mix 100 g peanuts with 100 ml water and put them in a blender to prepare peanut slurry;

[0029] 2. Take 0.7 ml of the peanut slurry prepared in step 1, mix with 4.34 g of cerium nitrate and 4.04 g of ferric nitrate, and stir for 60 minutes;

[0030] 3. Add a NaOH aqueous solution with a concentration of 0.5 M to the mixed solution prepared in step 2, and stir for 30 min;

[0031] 4. Put the mixed liquid prepared in step 3 into the autoclave, seal it, and keep it warm at 180 ºC for 1 hour;

[0032] 5. Cool the high-pressure reactor after heat preservation, pour out the liquid therein, filter and dry;

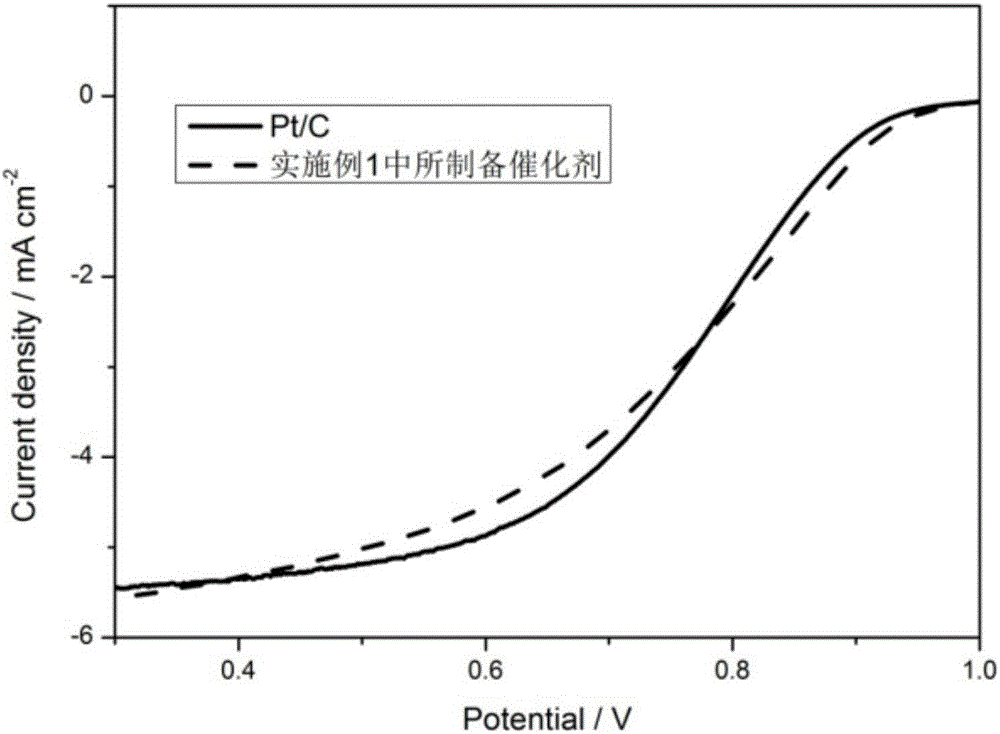

[0033] 6. Place the product obtained in step 5 in a hydrogen atmosphere, heat and hold it at 300°C for 6 h, and obtain a non-platinum catalyst for the cathode of a proton exchange membrane fuel cell with good oxygen reduct...

Embodiment 2

[0037] A method for preparing a proton exchange membrane fuel cell cathode catalyst with good oxygen reduction activity, the specific steps are:

[0038] 1. Mix 100 g peanuts with 1000 ml water and put them in a blender to prepare peanut slurry;

[0039] 2. Take 15 ml of the peanut slurry prepared in step 1, mix with 4.3 g of cerium nitrate and 4 g of ferric sulfate, and stir for 60 min;

[0040] 3. Add a NaOH aqueous solution with a concentration of 15 M to the mixed solution prepared in step 2, and stir for 30 min;

[0041] 4. Put the mixture prepared in step 3 into the autoclave, seal it, and keep it warm at 80 ºC for 24 hours;

[0042] 5. Cool the high-pressure reactor after heat preservation, pour out the liquid therein, filter and dry;

[0043] 6. Place the product obtained in step 5 in an atmosphere of carbon monoxide, and heat it at 500°C for 1 h. After cooling, a proton exchange membrane fuel cell cathode catalyst with good oxygen reduction activity is obtained.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com