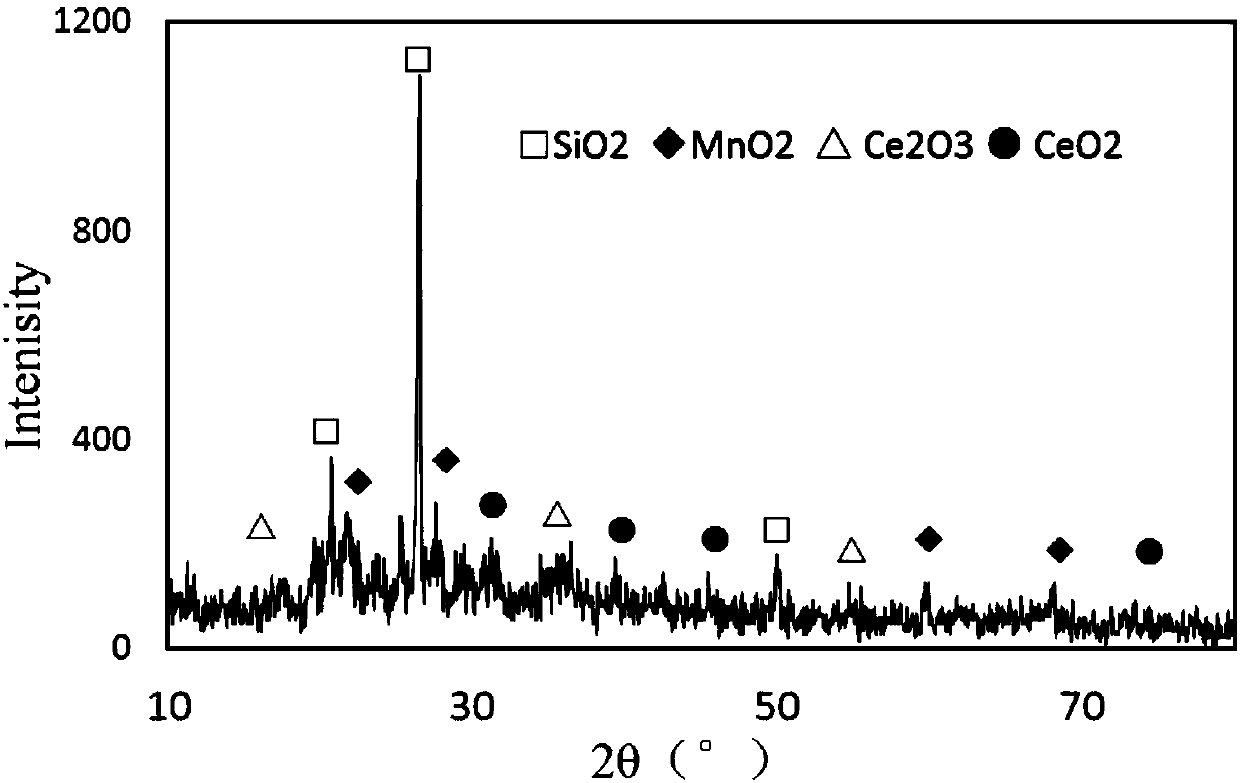

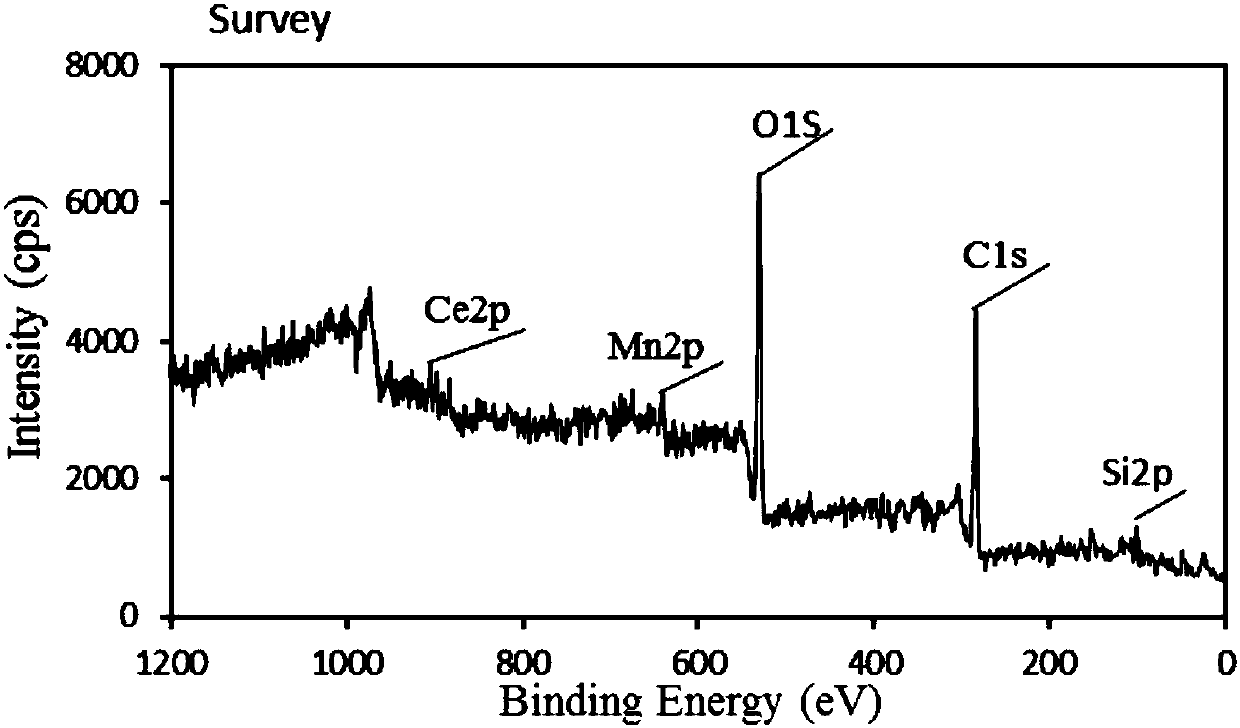

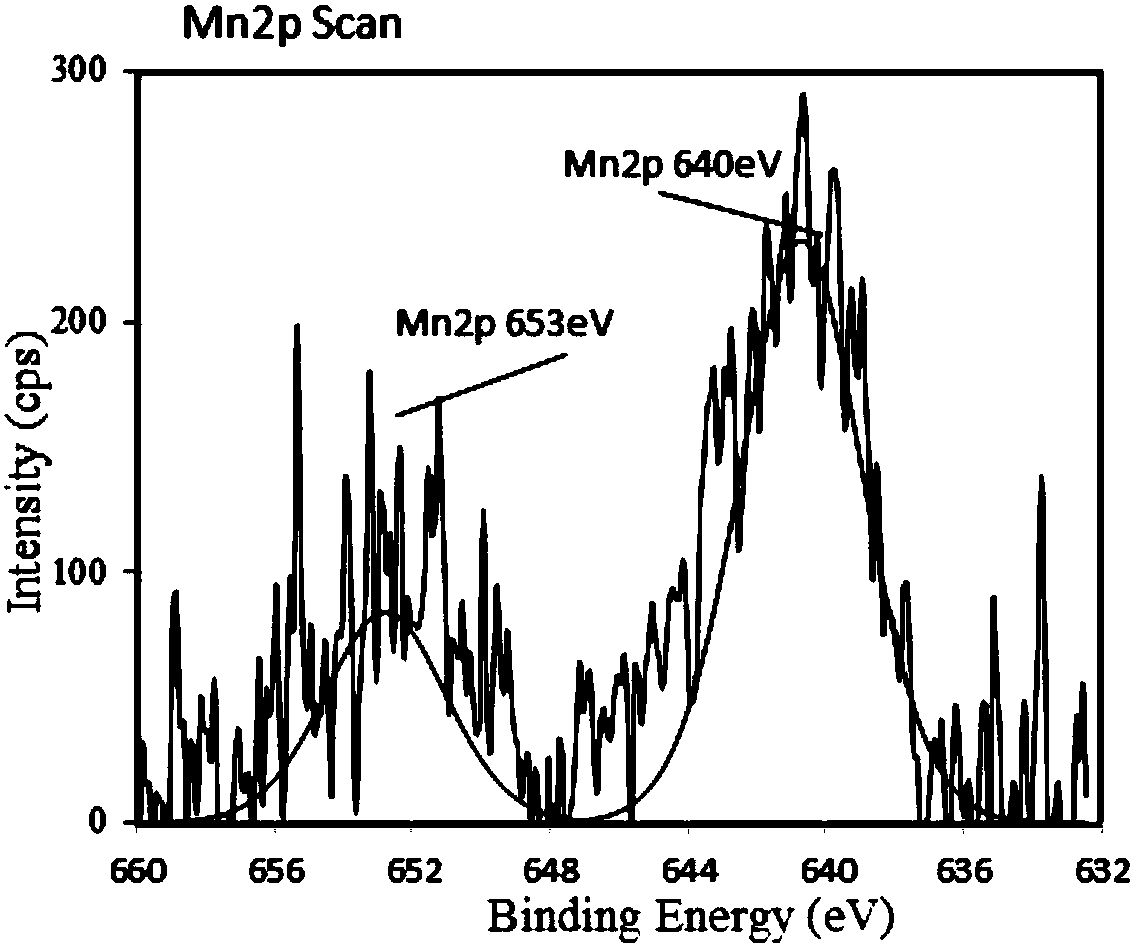

Preparation method of modified fly ash loaded mn-ce bimetallic denitrification catalyst

A denitrification catalyst and fly ash technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve high temperature, long time, easy agglomeration of catalyst, etc. problem, to achieve the effect of increasing the concentration of free electrons, enhancing the conductivity, and enhancing the catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for preparing the modified fly ash loaded Mn-Ce bimetallic denitration catalyst in this embodiment comprises the following steps:

[0034] Step 1. Mix fly ash, bentonite and distilled water evenly, extrude them into strips, place the strips in an oven, and dry them at a temperature of 90°C. Then dry the strips after drying. The material is sheared to obtain fly ash particles; the mass ratio of the fly ash and bentonite is 2:1, and the quality of the distilled water is 67% of the total mass of the fly ash and bentonite;

[0035] Step 2, place the fly ash particles described in step 1 in the plasma reactor, then feed oxygen into the plasma reactor, so that the power of the fly ash particles in the plasma reactor is 45W, the gas The flow rate is 40mL / min under the condition of modification treatment 25min, obtains modified fly ash;

[0036] Step 3. Manganese nitrate is loaded onto the modified fly ash described in step 2 by an equal volume impregnation method t...

Embodiment 2

[0054] The method for preparing the modified fly ash loaded Mn-Ce bimetallic denitration catalyst in this embodiment comprises the following steps:

[0055] Step 1. Mix fly ash, bentonite and distilled water evenly, extrude into strips, place the strips in an oven, and dry them at a temperature of 100°C, and then dry the strips after drying. The material is sheared to obtain fly ash particles; the mass ratio of the fly ash and bentonite is 3:1, and the quality of the distilled water is 70% of the total mass of the fly ash and bentonite;

[0056] Step 2, place the fly ash particles described in step 1 in the plasma reactor, then feed nitrogen into the plasma reactor, so that the power of the fly ash particles in the plasma reactor is 50W, the gas The flow rate is 45mL / min under the condition of modification treatment 20min, obtains modified fly ash;

[0057] Step 3. Manganese chloride is loaded onto the modified fly ash described in step 2 by an equal volume impregnation metho...

Embodiment 3

[0062] The method for preparing the modified fly ash loaded Mn-Ce bimetallic denitration catalyst in this embodiment comprises the following steps:

[0063] Step 1. Mix fly ash, bentonite and distilled water evenly, extrude them into strips, place the strips in an oven, and dry them at a temperature of 80°C. Then dry the strips after drying. The material is sheared to obtain fly ash particles; the mass ratio of the fly ash and bentonite is 1:1, and the quality of the distilled water is 60% of the total mass of the fly ash and bentonite;

[0064] Step 2, place the fly ash particles described in step 1 in the plasma reactor, then feed argon into the plasma reactor, so that the power of the fly ash particles in the plasma reactor is 40W, The gas flow rate is 35mL / min and modified for 30 minutes to obtain modified fly ash;

[0065] Step 3. Manganese sulfate is loaded onto the modified fly ash described in step 2 by an equal volume impregnation method to obtain a manganese-contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com